According to the London Cycling Campaign (LCC), though only five percent of all motor traffic in the UK's capital are lorries (trucks), they account for half of all cycling deaths in the Greater London area. Last November, the group launched its Safer Lorries, Safer Cycling campaign – which calls on councils to take a pledge that insists on cyclist-aware training for drivers and the use of the latest safety technology in all council-operated lorries and for all lorry contractors. Now LCC has released details of a lorry design overhaul that helps make cyclists more visible to drivers, while also lowering the chances of a rider being dragged underneath the wheels.

In 2011, over 10,000 Londoners signed an LCC petition calling for widespread adoption of a lorry driver training program, which includes giving drivers first-hand experience of riding a bike in London. Transport for London rallied to the call in October 2012 and introduced a strict set of safer lorries conditions for every one of its transport and freight suppliers, including compulsory driver training. While this aspect of the campaign continues to gain momentum, LCC is embarking on the next phase.

Taking inspiration from the open cab design of modern refuse (garbage) trucks, LCC has come up with a new safer lorry proposal that gives the driver improved all-round visibility, and employs a lower front bumper and sideguards to help increase the chances of a cyclist being pushed aside rather than being dragged underneath the wheels.

"Our Safer Urban Lorry design is a challenge to the construction industry to use vehicles that help reduce the terrible number of people on bikes and on foot who are killed by lorries," said LCC's haulage expert (and former lorry driver) Charlie Lloyd. "The restricted view from the cab of many of today’s construction lorries means the driver often has little or no idea who or what is in their immediate vicinity, which is totally unacceptable."

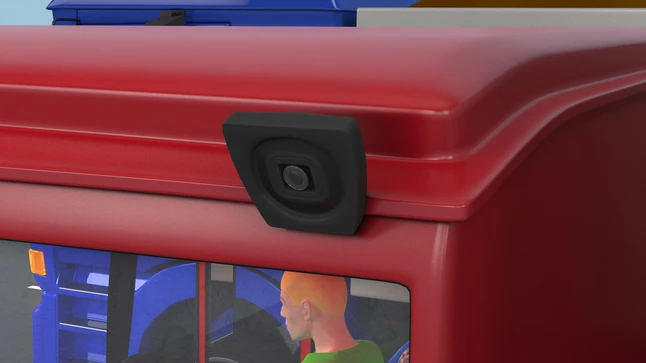

LCC points out that the most common response from lorry drivers after a fatal crash is that they didn't see the victim before the collision. To help address this, the windshield and side windows are much larger in the new design, and a lower chassis puts the driving position about 60 cm (almost two feet) lower than in a conventional construction industry lorry. The installation of a side-mounted camera could also act as an early warning system for drivers, further increasing visibility around the vehicle.

Naturally, any improvements to lorry design resulting from the LCC campaign will be beneficial to pedestrians and motorcyclists, too.

The group has produced a short video comparing the traditional lorry design with LCC's proposal, which can be seen below.

Source: London Cycling Campaign