A remarkable pilot project installed on a 240-m (787-ft) container ship has proven it's possible to capture at least 78% of emissions from the smokestacks of cargo ships and convert the CO2 into limestone pebbles, which can be offloaded and sold.

London startup Seabound, funded by a US$1.5-million grant from the UK Government, partnered up with global shipping company Lomar to install the carbon capture equipment on one of its older and dirtier-burning ships, a medium-sized vessel capable of carrying more than 3,200 shipping containers.

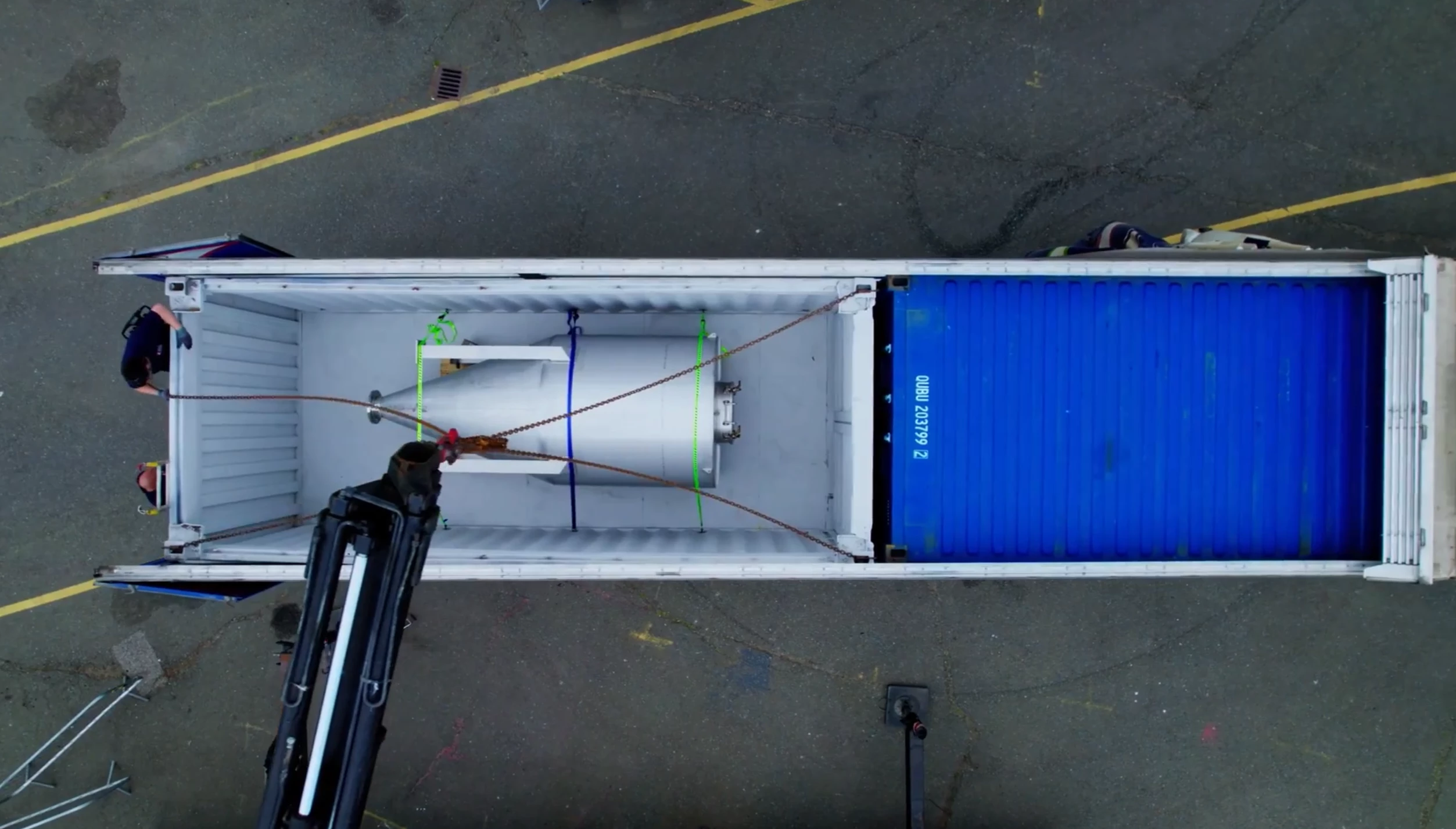

Seabound's small prototype system itself fits in a few shipping containers, taking up very little room aboard the ship. It's designed as a retrofit, attaching to a ship's exhaust to capture the carbon dioxide and sulfur emissions from dirty marine diesel as it burns.

The exhaust gas is pushed through a pile of calcium oxide pebbles – also known as quicklime, and a relatively cheap and abundant material used in building, agriculture and other areas worldwide. Carbon dioxide readily reacts with quicklime at room temperatures to create calcium carbonate, or limestone – so these pebbles securely bind and trap the carbon dioxide.

If you're buying and selling in North America, quicklime cost about $200 per tonne at the end of last year, and calcium carbonate was selling for as much as $727/tonne. Well, food-grade calcium carbonate, anyway; we suspect lime pulled straight out of a marine diesel's exhaust might not quite qualify there. Europe was buying industrial-grade lime for $340/tonne.

The point stands; by capturing smokestack emissions and storing them in pebbles, this system takes a cheap commodity and transforms it into a more valuable one, offering a revenue stream that could help offset the capital and operational costs of running the system.

Over a couple of months on board the container ship, the young Seabound team ran a series of tests, gradually improving the rate of emissions capture until they were managing 78% carbon capture efficiency and more than 90% sulfur capture – but the team says the system will eventually be able to capture anywhere up to 95% of emissions in its most effective form.

The team captured the pilot voyage in a short film, which explains more:

The prototype captured about 1 tonne of CO2 emissions per day during the test – so it certainly wasn't grabbing the entire exhaust plume. A medium-large container ship might carry somewhere around 150,000 tonnes of cargo, and might emit somewhere around 600 tons of CO2 per day on the sea. Capture 95% of that, and it's gonna add up.

Back of the envelope, let's take a nice quick 15-day trip from China to the West Coast of the USA. At a 95% capture rate, you'll end up with 8,550 tons of CO2 captured. At its theoretical maximum, quicklime can capture 78.6% of its weight in carbon dioxide, so you'll need, what, nearly 11,000 tons of quicklime, plus the weight of the containers it's stored in, plus the weight of the system itself ... That could easily add up to around a fifth of the ship's rated tonnage – and there are voyages that sail for three times as long.

That's not to denigrate what Seabound is doing in any way, it's just to illustrate the sheer bulk of the problem here. Cargo ships represent an extremely hard-to-decarbonize source of some 3% of the world's total carbon emissions. Progress is being made with ammonia, methanol and other cleaner solutions, but there are no simple fixes here. Onboard carbon capture solutions like this could play a valuable part in the next few transitional decades, and we wish the Seabound team all the best in bringing this idea to scale.

“Our pilot project demonstrates that we can capture carbon emissions directly onboard ships in a simple and cost-effective way, said Alisha Fredriksson, CEO and Co-Founder of Seabound, in a press release. “This breakthrough demonstrates that the shipping industry doesn’t have to wait for new fuels or solutions to reduce its emissions in the future - we can start to capture carbon from the existing fleet today.”

Source: Seabound