Using machine learning, a team of researchers in Canada has created ultrahigh-strength carbon nanolattices, resulting in a material that's as strong as carbon steel, but only as dense as Styrofoam.

The team noted last month that it was the first time this branch of AI had been used to optimize nano-architected materials. University of Toronto's Peter Serles, one of the authors of the paper describing this work in Advanced Materials, praised the approach, saying, "It didn’t just replicate successful geometries from the training data; it learned from what changes to the shapes worked and what didn’t, enabling it to predict entirely new lattice geometries."

To quickly recap, nanomaterials are engineered by arranging atoms or molecules in precise patterns, much like constructing structures with extremely tiny LEGO blocks. These materials often exhibit unique properties due to their nanoscale dimensions.

These atoms or molecules are arranged in repeating three-dimensional patterns known as lattices. A lattice consists of regularly spaced points (called lattice points), which define the periodic structure of the material. This ordered arrangement influences the material’s physical, chemical, and electronic properties.

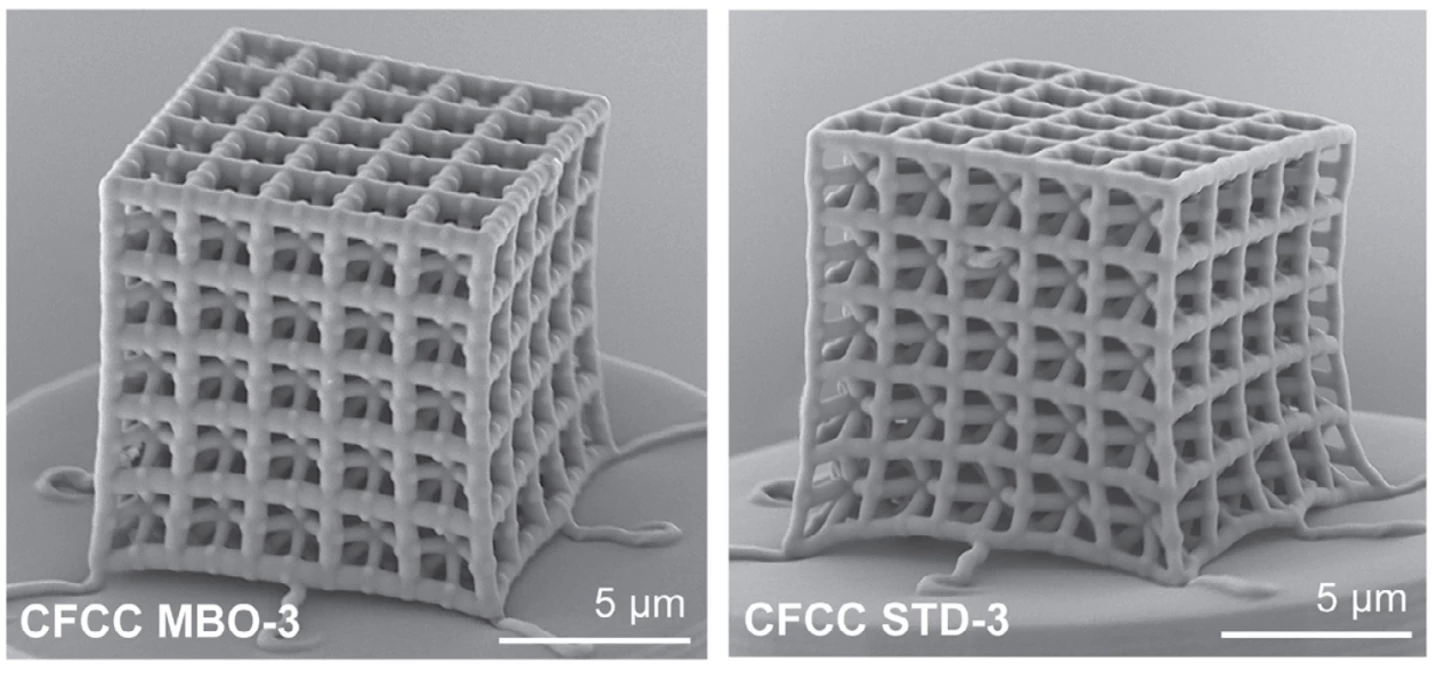

The researchers collaborated with a team in South Korea, and applied what's known as the multi-objective Bayesian optimization machine learning algorithm. Its role was to predict the best possible geometries for enhancing stress distribution and improving the strength-to-weight ratio to arrive at a novel nano-architecture.

Next, they used a two-photon polymerization 3D printer to create a precise nanoscale prototype using a high-resolution additive manufacturing technology. The machine they used – a Nanoscribe Photonic Professional GT2 – is said to cost hundreds of thousands of dollars.

The nanolattices they produced withstood five times the amount of stress that titanium can. That resulted in a strong, stiff, yet light material that could potentially find use in aerospace manufacturing applications.

"If you were to replace components made of titanium on a plane with this material, you would be looking at fuel savings of 80 liters per year for every kilogram of material you replace,” Serles noted.

The team intends to continue its work to develop even stronger and less dense materials in this vein, and also figure out ways to manufacture components with these material designs without breaking the bank.

Source: University of Toronto