Bamboo plastic sounds like a compelling eco-friendly material for a variety of applications, but its questionable durability and recyclability leave a lot to be desired.

Researchers at Northeast Forestry University in Harbin, China have a solution: their new method for producing bamboo-based plastic results in a stronger material that can compete with traditional plastics, and can also degrade in soil in less than two months.

That's a big step up over bamboo plastic composites used to make household items like serveware and cutlery that you might have seen in a local store.

These usually feature a bamboo fiber-based filler surrounded by an epoxy resin or similar polymer matrix. Those may look like more sustainable options over regular plastic, but the use of plastic matrices make them hard to recycle.

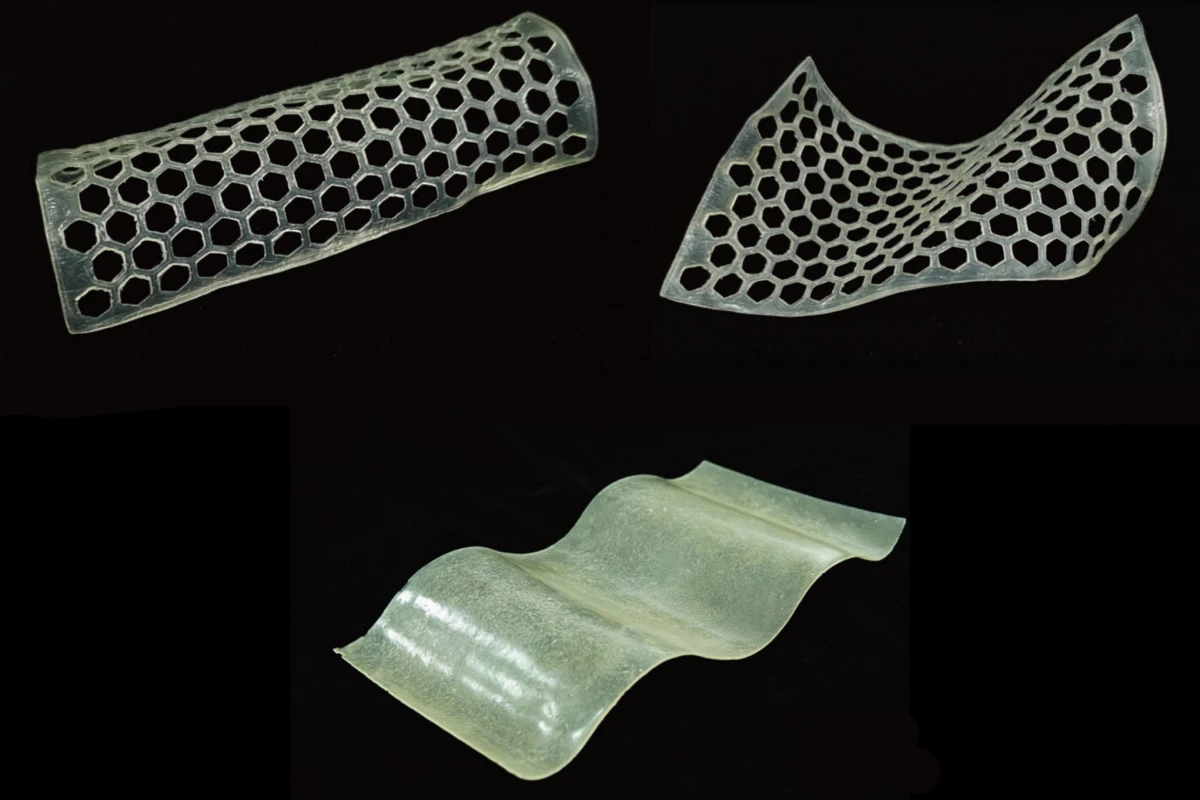

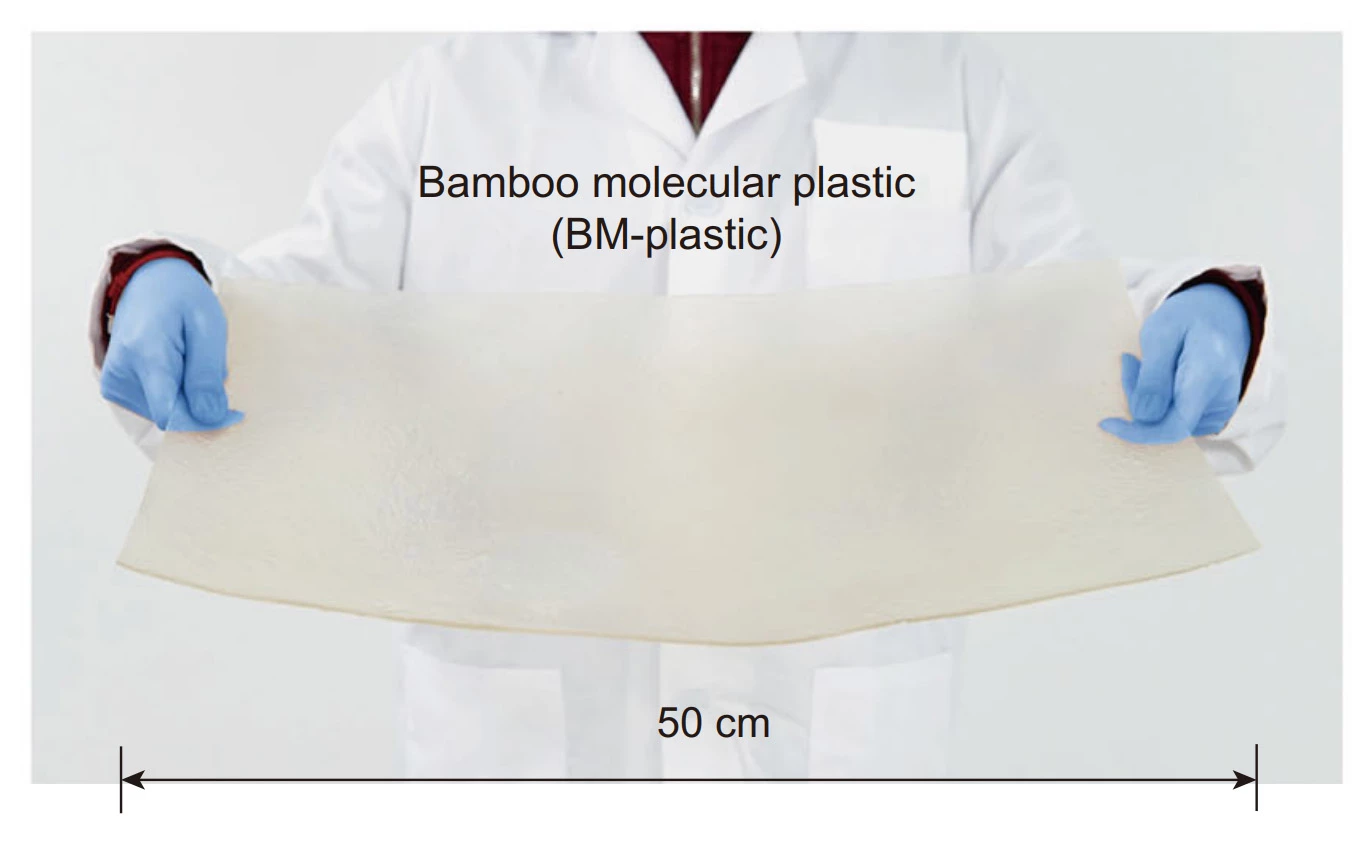

The scientists' new solvent-mediated molecular engineering strategy uses a two-step process to create a better bamboo molecular plastic. First, bamboo cellulose is dissolved using a non-toxic alcohol solvent. Then it's treated to trigger the cellulose chains to pack tightly together, producing a strong and stable plastic that can be shaped and formed in many different ways for use in automotive and infrastructure applications.

Indeed, the team's study, which appeared in Nature Communications this week, notes the bamboo plastic displays a tensile strength and work of fracture (force required to fracture a material) higher than that of traditional plastics. Plus, it fully breaks down in soil, and can alternatively be recycled in a closed loop so you get a material with 90% of the strength of the original. How's that for a sustainable alternative to oil-based plastics?

Source: Northeast Forestry University via Scimex