Rare earth elements are a key part of electronic and mechanical devices, but they’re in short supply. Now, scientists have found a way to recreate a promising alternative – a “cosmic magnet” that normally takes millions of years to form in meteorites can now be cooked up in the lab in seconds.

Many of our electronic devices and mechanical components rely on rare earths. That’s especially true for greener technologies – high-performance magnets, which are vital for everything from wind turbines to electric cars, require these elements. But unfortunately, although not actually rare in the Earth's crust, they’re difficult to mine and their production is currently concentrated in China, leading to supply concerns.

“Rare earth deposits exist elsewhere, but the mining operations are highly disruptive: you have to extract a huge amount of material to get a small volume of rare earths,” said Professor Lindsay Greer, lead researcher on the study. “Between the environmental impacts, and the heavy reliance on China, there’s been an urgent search for alternative materials that do not require rare earths.”

As such, scientists have been investigating ways to recycle rare earths from old batteries and electronics, extract them from new sources like wastewater, and find more common minerals that could perform similar functions.

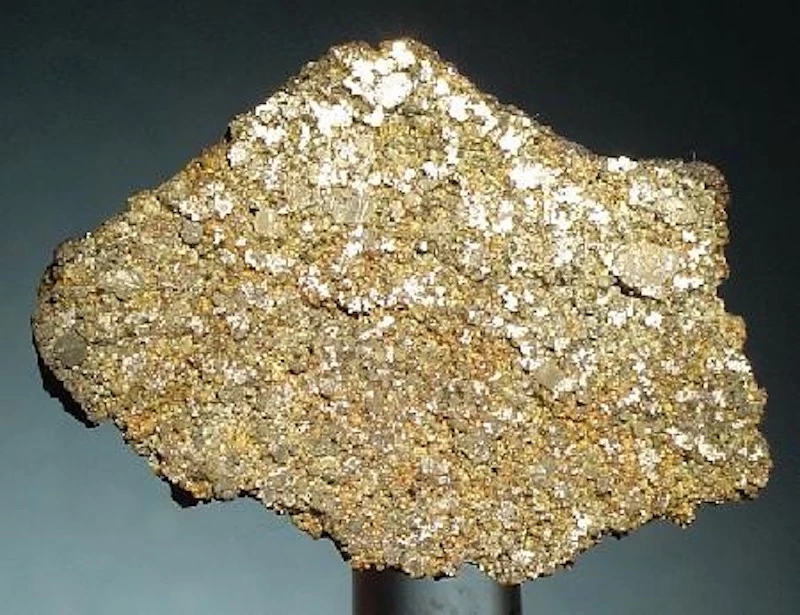

In the new study, researchers from Cambridge investigated a promising alternative called tetrataenite. This mineral is an alloy of iron and nickel arranged in a stacked crystalline structure, which gives it magnetic properties similar to those of rare earth magnets. The advantage of course is that iron and nickel are much easier to come by.

The problem is, tetrataenite is tricky to find – it mostly shows up in meteorite samples, where it’s thought to have taken millions of years to form. Previous attempts to produce it artificially in the lab have shown some success, but the techniques aren’t scalable.

On closer inspection of meteorite samples of tetrataenite, the team found that phosphorus was in the mix, helping to speed up the arrangement of the iron and nickel atoms into the stack structure. So, they mixed iron, nickel and phosphorus together in specific quantities, and found that tetrataenite formed up to 15 orders of magnitude faster – essentially, in seconds.

“What was so astonishing was that no special treatment was needed: we just melted the alloy, poured it into a mold, and we had tetrataenite,” said Greer. “The previous view in the field was that you couldn’t get tetrataenite unless you did something extreme, because otherwise, you’d have to wait millions of years for it to form. This result represents a total change in how we think about this material.”

The team says this discovery could lead to a viable alternative to rare-earth magnets – although more work will be required to check whether tetrataenite created this way will work in these magnets.

The research was published in the journal Advanced Science.

Source: University of Cambridge