Airborne bacteria and other pathogens can be a real hazard, particularly in environments like hospitals. Now, researchers at Rice University have developed a new air filter made of graphene foam, which can kill captured microbes with small zaps of electricity.

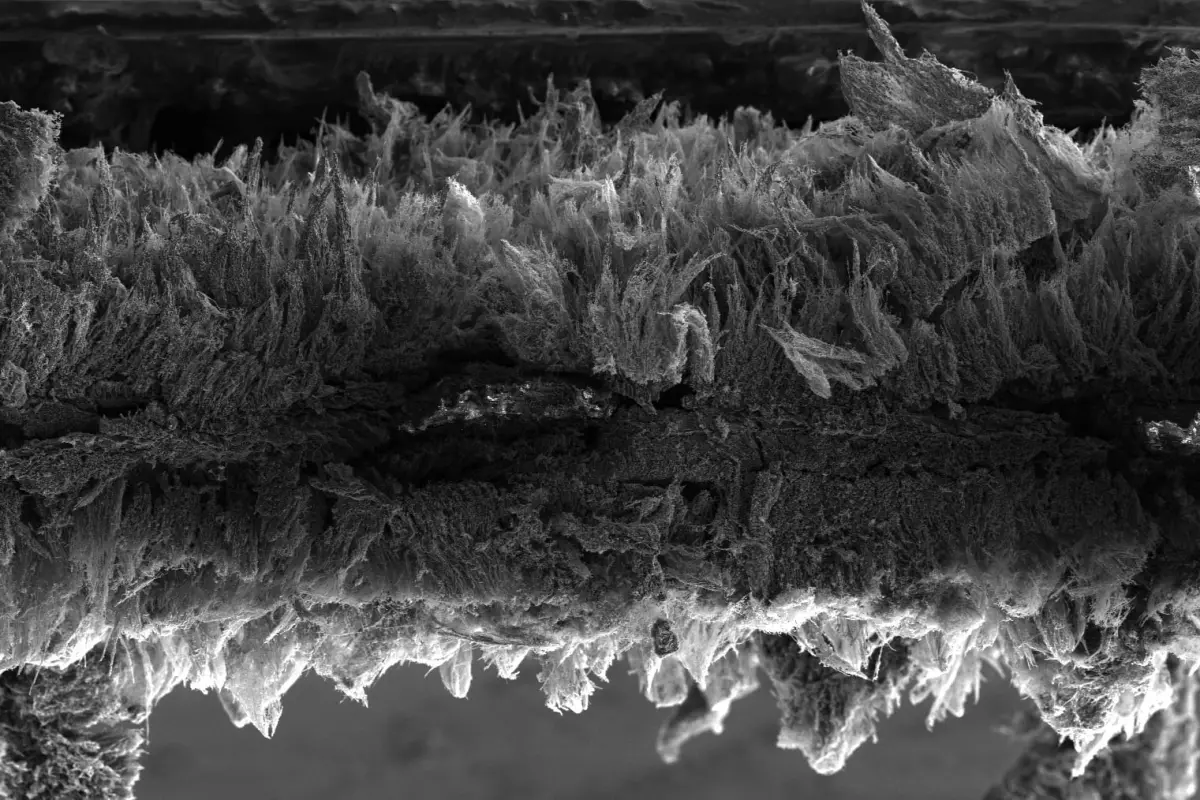

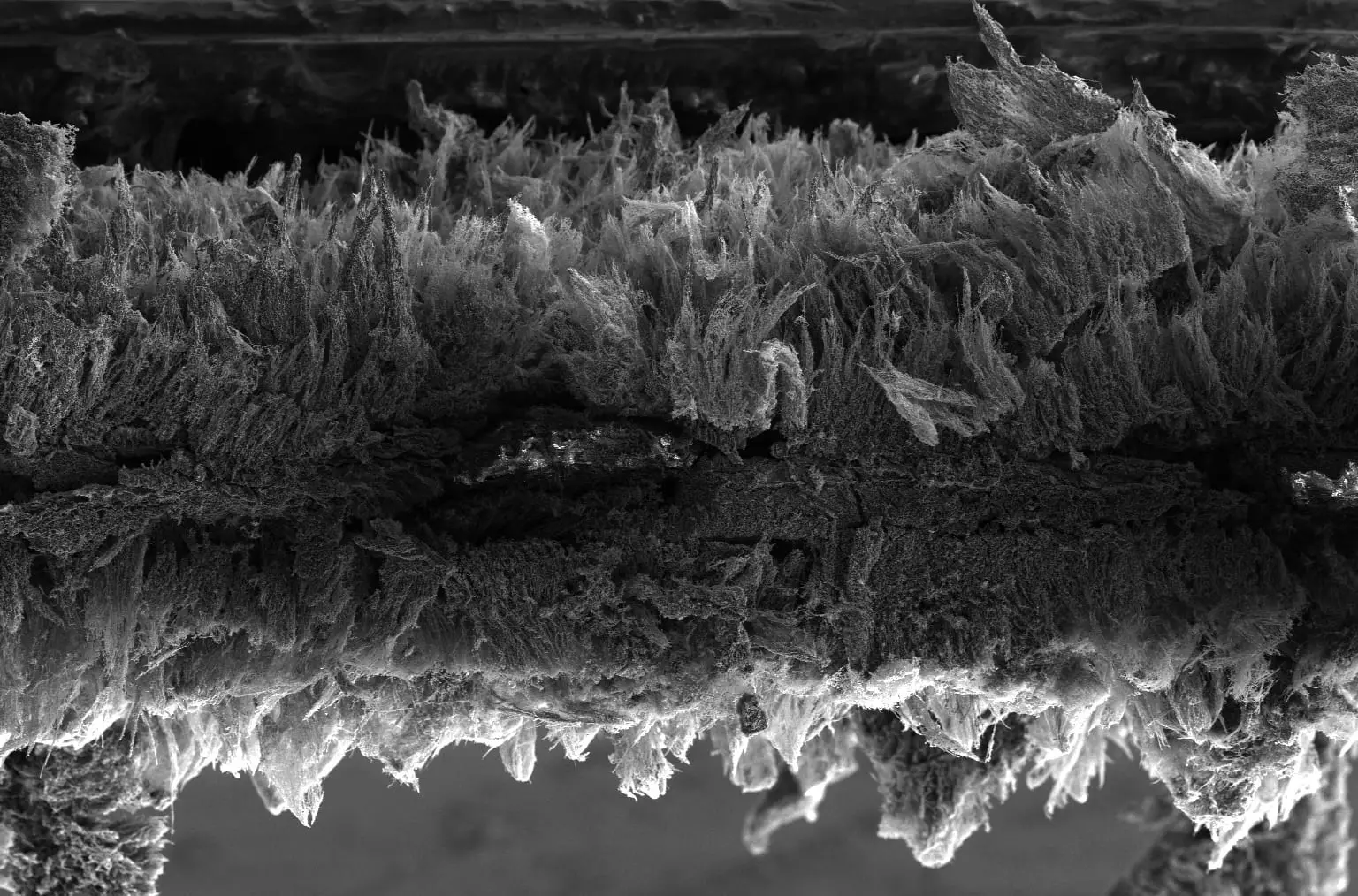

The device is made using a type of graphene previously created at Rice called laser-induced graphene (LIG). As the name suggests, this material is made by zapping a sheet of polyimide with a laser, which causes it to puff out into a foamy form of graphene.

In this case, the team blasted both sides of the polyimide with a laser cutter, leaving a thin lattice of the polymer in the center to reinforce the structure. By using different temperatures of the laser, the team could fluff the graphene fibers out to different extents, creating a thick forest on the outside and smaller interconnected sheets deeper in.

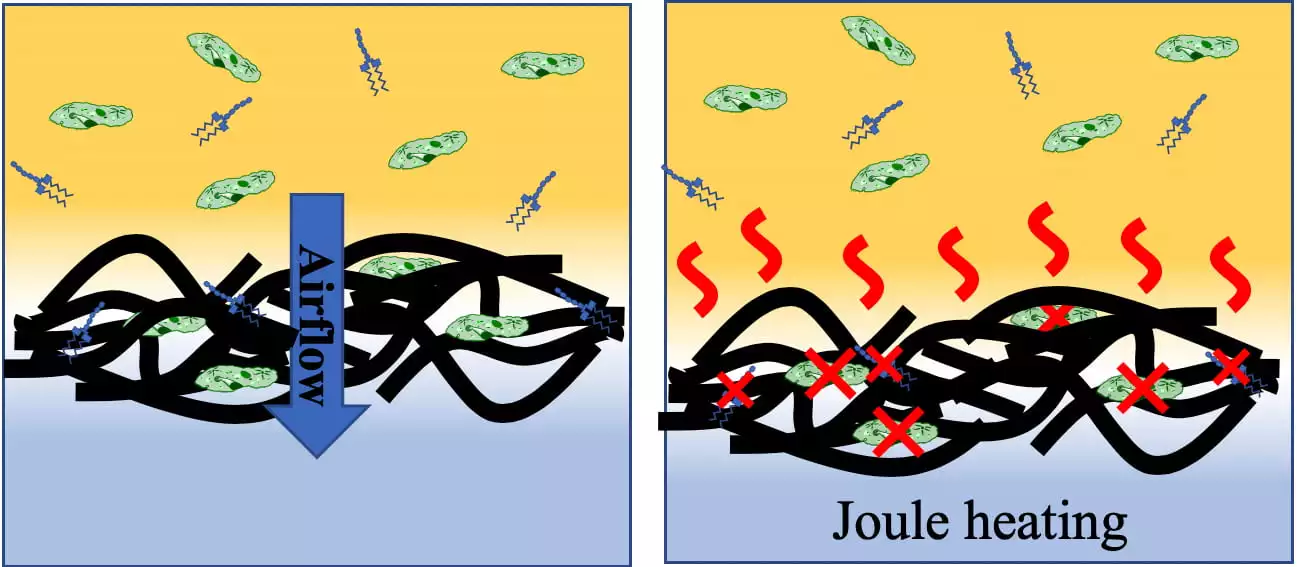

Having this much surface area makes LIG the perfect spot for airborne bacteria, fungi, spores, prions, endotoxins and other biological contaminants to settle. And when they do, they’re in for a shock.

Graphene is famously a great conductor of electricity, and this foamy LIG is no different. A small current is passed through the Rice team’s filter to periodically heat it to 350° C (662° F) and kill anything caught in the trap. According to the team it only takes a few seconds to heat and cool the material, and doesn’t take much power.

The team tested the new filter design in a commercial vacuum filtration system, which cycles through 10 L (2.6 gal) of air per minute. Two groups of the LIG filters were tested for 90 hours in this system – one group was zapped and heated periodically, while the other just passively captured microbes without any self-sterilization.

At the end of the test, the two groups of filters were incubated for 130 hours at temperatures that encouraged bacterial growth. The control filters that hadn’t been zapped showed regular levels of bacterial growth, but those that had been electrified showed none at all.

That’s not to say that the filters are useless without being electrified. In another test the team placed a membrane downstream from a LIG filter, and showed that bacteria didn’t grow on the surface as readily. That indicates that they still have a hard time passing through the filter, so they could still be used as passive filters.

The team says that these LIG filters, electrified or not, could be put to use in filtration systems in places like hospitals or commercial aircraft, where airborne pathogens tend to spread quickly. This could form an important part of our defenses against the rising tide of antibiotic-resistant bacteria.

The research was published in the journal ACS Nano.

Source: Rice University