Imagine getting a flat tire, but instead of swapping it out for a new one you just smear on a chemical that makes the rubber meld seamlessly back together. That’s the kind of breakthrough researchers at Australia’s Flinders University are now reporting, and better yet the material is made of waste products and can be easily recycled itself.

The new material is made up of more than 50 percent sulfur, mixed with some canola cooking oil and a chemical compound called dicyclopentadiene (DCPD). This unusual concoction makes for a versatile and sustainable new form of rubber.

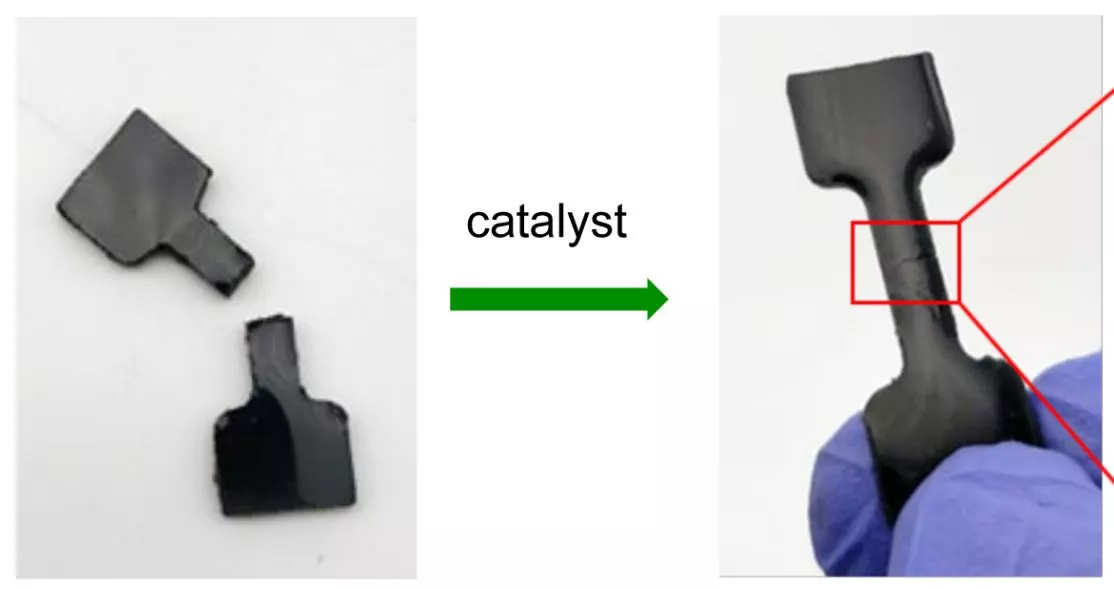

But the weirdest part is that this material is a “latent adhesive” – basically, glue waiting for its cue. The missing ingredient is an amine catalyst, and once that’s applied the rubber becomes sticky again, allowing it to bond with itself so completely that it doesn’t lose any strength.

“The rubber bonds to itself when the amine catalyst is applied to the surface,” says Tom Hasell, an author of the study. “The adhesion is stronger than many commercial glues. The polymer is also resistant to water and corrosion.”

The team says that the bonding can be done at room temperature, and takes just minutes. That could make it useful for repairing rubber objects like tires on the fly, and when their useful life is over, makes them much easier to recycle.

As an added bonus, the three main ingredients used to make the stuff in the first place are all industrial waste products. DCPD, for example, is a by-product of petroleum refining. That means it’s cheap and environmentally friendly to produce the new material.

“This study reveals a new concept in the repair, adhesion and recycling of sustainable rubber,” says Justin Chalker, lead researcher on the study. “It is exciting to see how the underlying chemistry of these materials has such wide potential in recycling, next-generation adhesives, and additive manufacturing.”

The research was published in the journal Chemical Science. The team describes the work in the video below.

Source: Flinders University