Hokkaido University’s ongoing research into hydrogels has borne fresh fruit: a new polymer-based material that, unlike other polymers, hardens when heated – by 1,800 times.

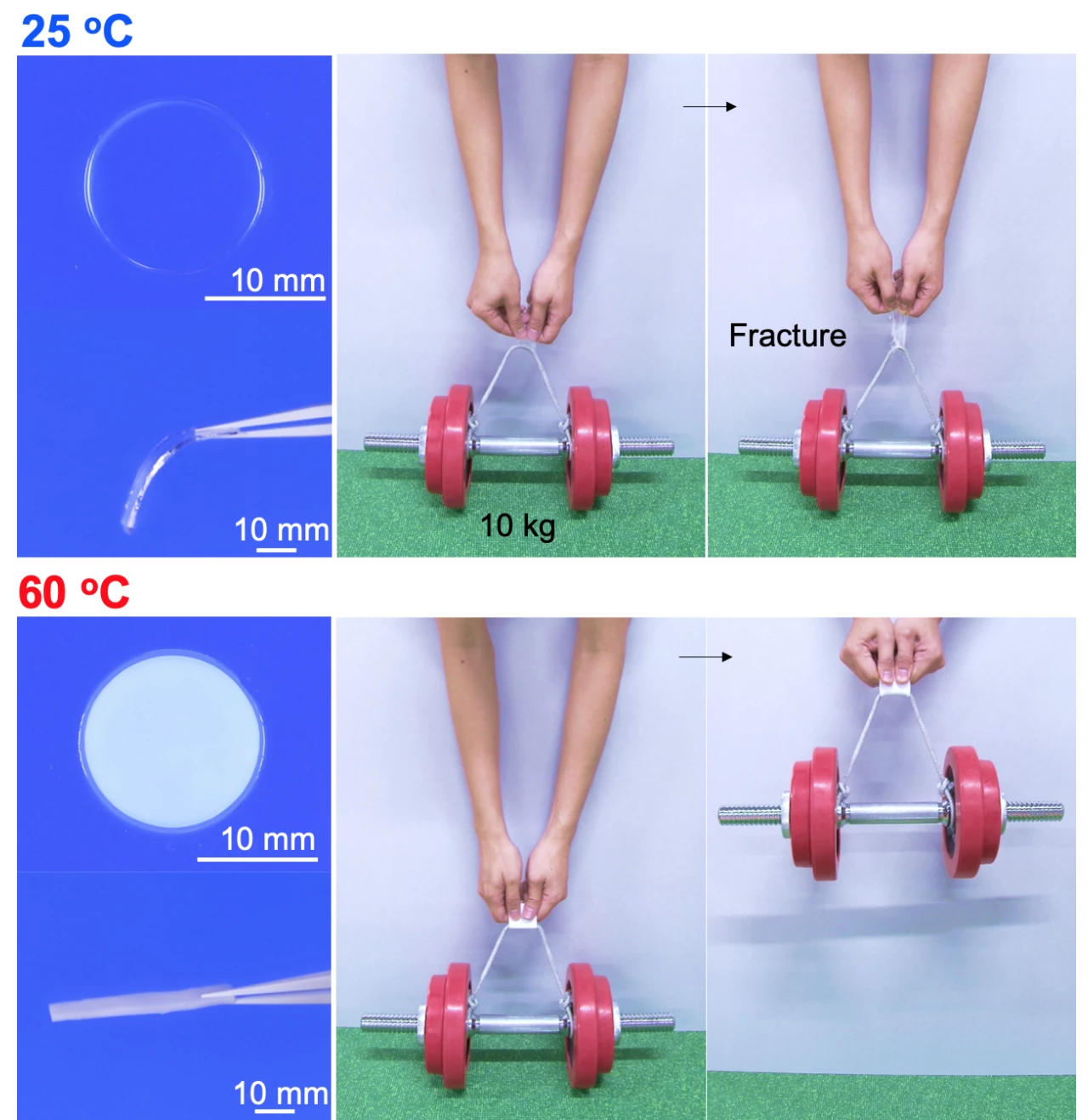

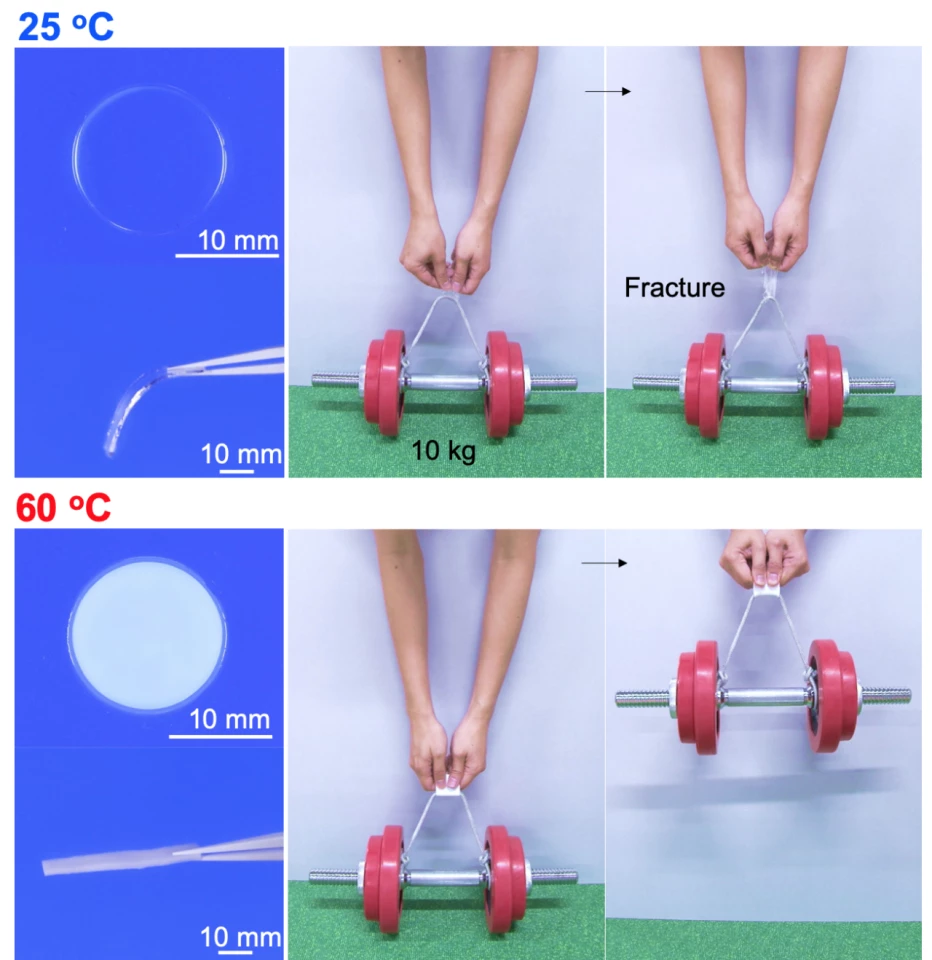

At room temperatures the substance is a soft see-through gel. But heated to 60° C (140° F), it hardens, turns opaque, and becomes strong enough to lift a 10-kg (22-lb) weight.

Hokkaido researchers Takayuki Nonoyama and Jian Ping Gong were apparently inspired by natural proteins that stay stable inside thermophiles – organisms living in extremely hot environments like springs or deep-sea thermal vents. Such proteins would ordinarily denature, but those inside thermophiles have adapted to the high temperatures to stay stable.

The team was able to develop a cheap, safe polyacrylic gel by dunking polyacrylic acid into a calcium acetate solution. "Polyacrylic acids are used in disposable diapers and calcium acetates are used in food additives,” Jian Ping Gong explains in a press release.

Normally, like any polymer-based material, polyacrylic acid gets softer as it gets hotter, but when calcium acetate is applied, it interacts with polyacrylic residues at the surface, having the transformative effect.

At around 60° C, the material effectively dehydrates, strengthening its ionic bonds and becoming a strong hard plastic. As well as hardening 1,800 times, it becomes 80 times stronger and 20 times tougher than the room-temperature gel. (Strength measures a material’s ability to withstand stress, whereas toughness measures the energy needed to fracture it when it’s cracked.)

The researchers went on to combine the gel with a woven glass fabric. The mixture was soft at room temperature, but when pulled along asphalt for five seconds at 80 km/h (50 mph), the material hardened due to the heat caused by the intense friction. The researchers say that only minor marks were evident on the side in contact with the asphalt.

The choice of asphalt is significant, as the researchers say that rapidly-hardening materials of this kind could one day be used to give motorcyclists and racing drivers extra protection in the event of an accident. The researchers also suggest the material could be applied to windows to absorb heat and keep building interiors cool.

Back in 2017, we reported on Jian Ping Gong’s work developing a hydrogel five times stronger than carbon steel. In that case, the gel was combined with woven fiber.

The new research paper, Instant Thermal Switching from Soft Hydrogel to Rigid Plastics Inspired by Thermophile Proteins, has been published in the peer-reviewed journal Advanced Materials. It’s free to read online.

Source: Hokkaido University