Although lumber does show promise as a renewable alternative to structural materials such as steel and concrete, it still tends to be a bit weaker than those substances. Scientists have now set about addressing that shortcoming, by strengthening wood with added iron.

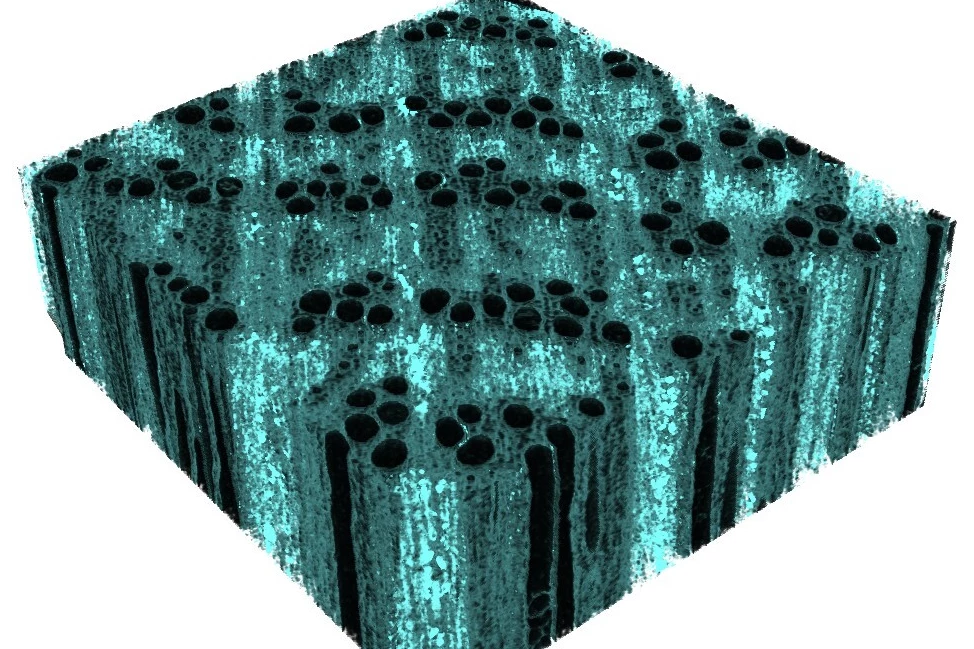

Led by Asst. Prof. Vivian Merk, a team of researchers at Florida Atlantic University (FAU) started out with cubes of untreated red oak hardwood. Red oak – along with hardwoods like maple, cherry and walnut – is an example of what's known as ring-porous wood. In a nutshell, this means that it utilizes large ring-shaped internal vessels to draw water up from the tree's roots to its leaves.

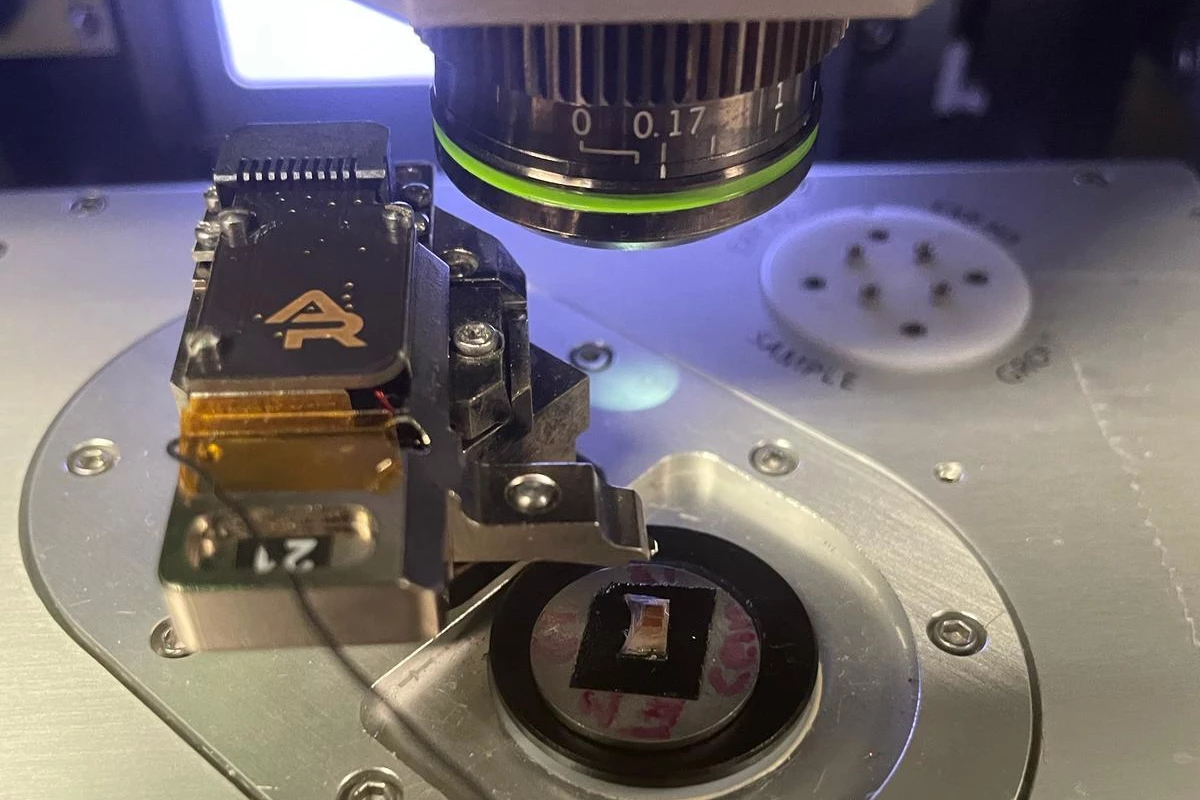

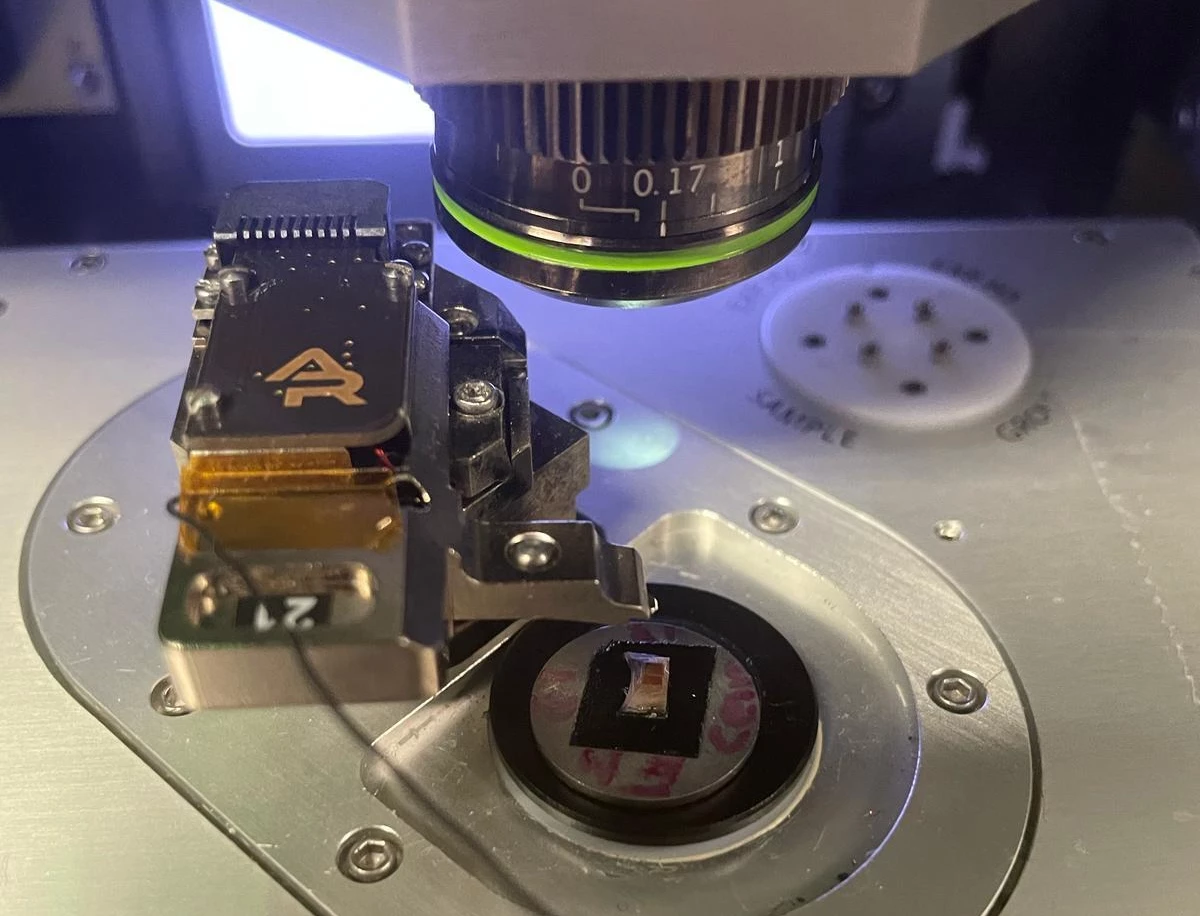

The scientists proceeded to mix ferric nitrate with potassium hydroxide, creating a hard iron oxide mineral called nanocrystalline ferrihydrite, which occurs naturally in soil and water. Utilizing a vacuum impregnation process, nanoparticles of that ferrihydrite were drawn into the wood and deposited inside of its individual cell walls.

This action served to strengthen those walls, thus increasing the stiffness and hardness of the wood by 260.5% and 127%, respectively. That said, when the modified red oak wood did bend or break, it did so in a manner much like that of unmodified test samples. This is likely due to the fact that although the wood's cell walls had been strengthened, the bonds between the cells had not.

Importantly, the addition of the ferrihydrite nanoparticles increased the weight of the wood by only a small amount. Additionally, because the particles are nontoxic, they shouldn't pose a threat to the environment when the wood is eventually discarded or recycled.

"Our researchers are laying the groundwork for a new generation of bio-based materials that have the potential to replace traditional materials like steel and concrete in structural applications," says Dr. Stella Batalama, dean of FAU's College of Engineering and Computer Science.

"The impact of this work reaches far beyond the field of engineering – it contributes to global efforts to reduce carbon emissions, cut down on waste, and embrace sustainable, nature-inspired solutions for everything from buildings to large-scale infrastructure."

A paper on the research – which also involved scientists from the University of Miami and Oak Ridge National Laboratory – was recently published in the journal ACS Applied Materials and Interfaces.

In a previous study, a team at Georgia Tech determined that impregnating wood with different types of metal oxide additionally helped keep it from rotting.

Source: Florida Atlantic University