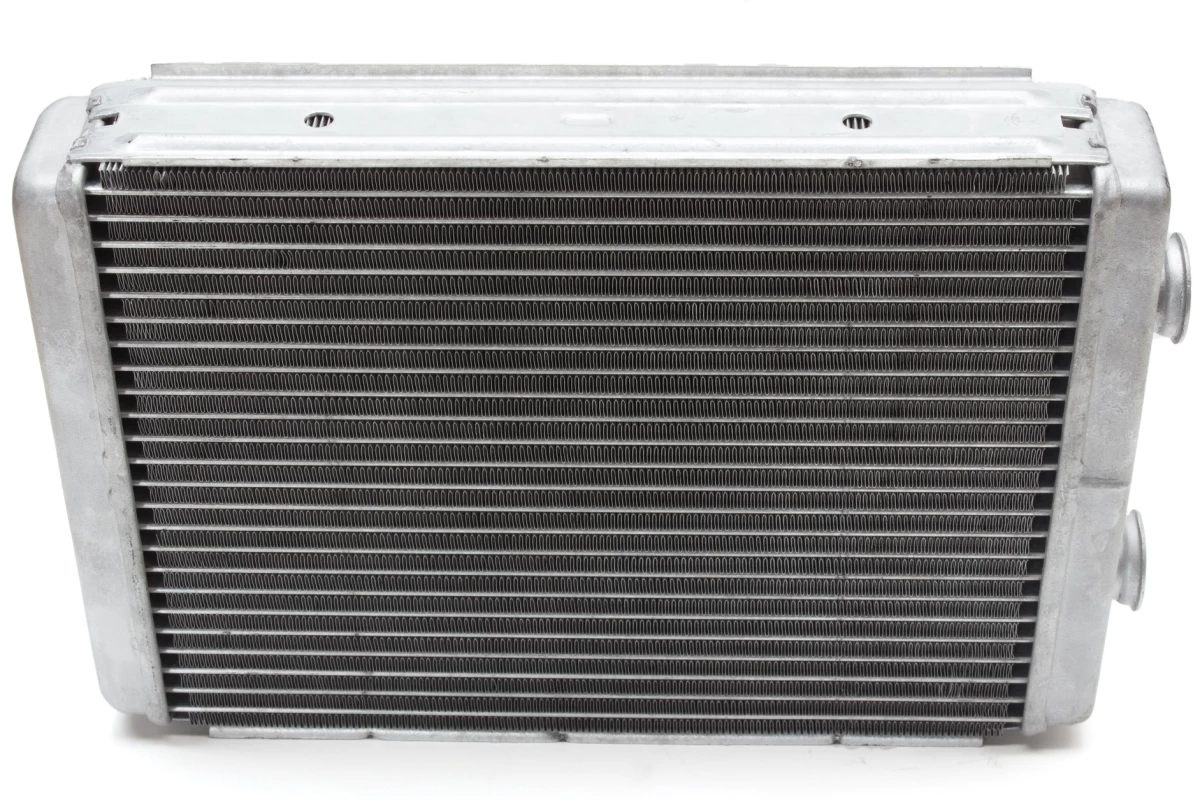

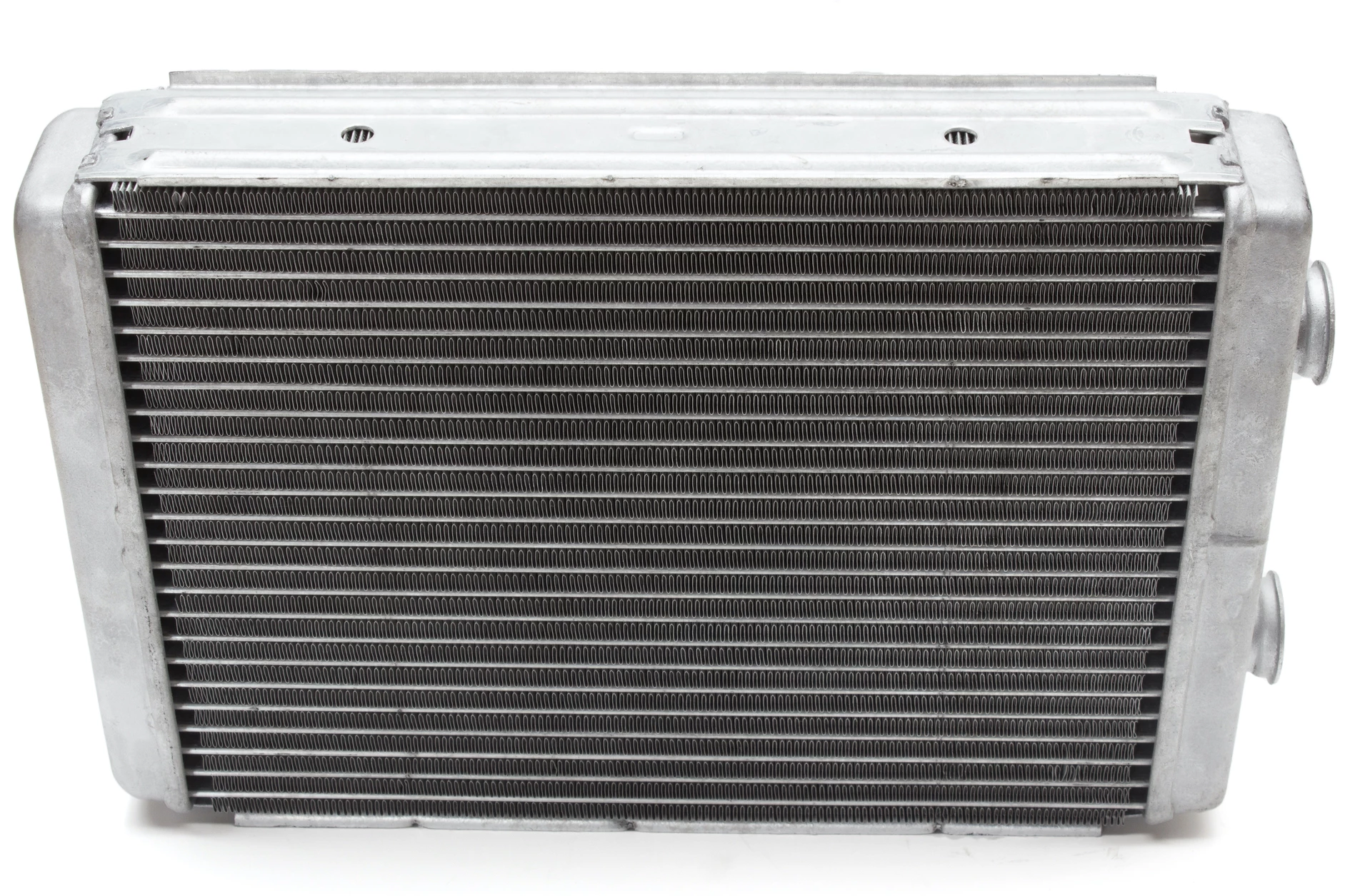

Both cars and electronic appliances require heat removal systems, which are typically made of iron, steel or aluminum. That may soon change, though, as scientists have created two magnesium alloys which they claim can reduce the weight of such systems by a third.

Developed via a collaboration between Russia's National University of Science and Technology (NUST) and LG Electronics, the new alloys could find use in devices like radiators and heat sinks.

In the past, other magnesium alloys have had at least one major drawback: when heated and exposed to air, they've ignited. According to the NUST team members, though, the addition of calcium and yttrium to their alloys gives the materials a much higher ignition temperature – to the point that they're reportedly safe for use "in various gadgets without restrictions."

Additionally, whereas existing magnesium alloys typically contain expensive elements like neodymium, lanthanum and thorium, the NUST alloys incorporate considerably cheaper alternatives.

The least costly of the two combines magnesium with silicon, zinc and calcium, resulting in high thermal conductivity and medium strength. The other, which is a bit pricier, combines magnesium with zinc, yttrium and zirconium, delivering slightly lower thermal conductivity but higher strength.

So far, the university hasn't stated how the cost of the alloys might compare to those of traditional heat-dissipating materials like cast iron, mild steel, stainless steel and aluminum. Use of the alloys, however, is said to "reduce the weight of heat-removing elements by a third without losing efficiency."

LG has registered patents on the less expensive of the two alloys, and on a radiator made of the material.

The research is described in two different papers recently published in the Journal of Magnesium and Alloys.

Source: NUST MISIS