Scientists experimenting with next-generation plastics at Finland's University of Turku have developed a form of the material with some impressive capabilities, most notably an ability to quickly break down after use. The eco-friendly "supramolecular" plastic is therefore highly recyclable and, with careful tuning of its water content, can be turned into an adhesive or even instantly self-heal when damaged.

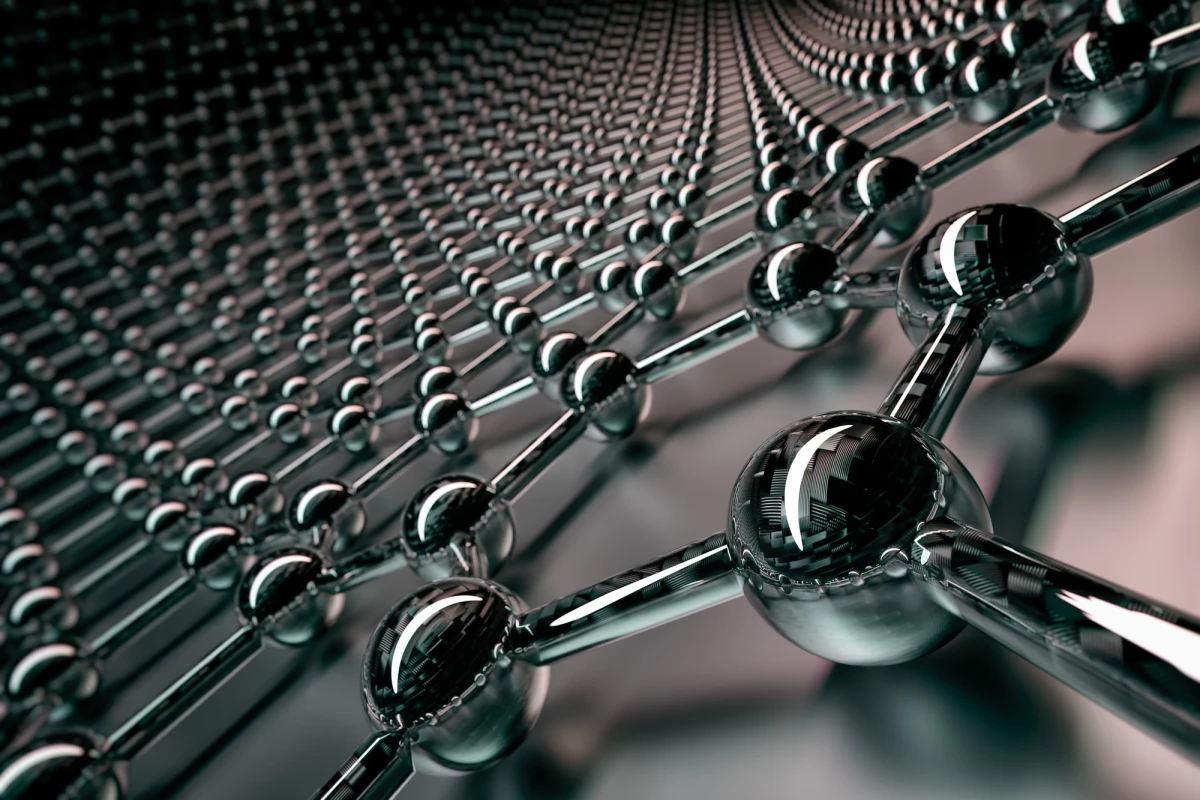

The reason conventional plastics persist in the environment for so long is the incredibly strong chemical connections between the monomers within them. These particles link up to form polymers through what are known as covalent bonds, but scientists hope to fashion more environmentally forms of the material based on non-covalent bonds instead.

These weaker connections are better suited to degradation and recycling of the material, but do come at a cost in terms of mechanical performance. We have looked at some interesting examples of these "supramolecular" materials in the form of hybrid polymers for drug delivery, self-assembling plastics and adhesives that work at extreme temperatures.

By leveraging a technique called liquid-liquid phase separation (LLPS), the authors of the new study say they've now developed a supramolecular plastic with the mechanical strength of conventional plastic. The material contains non-covalent bonds of high strength that are reversible, which enables it to be degraded or recycled after use, along with some other useful properties.

The plastic features a "remarkable" ability to be stretched and deformed with low water content, while increasing that water content turns it into an adhesive. Further, this higher water content enables the plastic to self-heal instantly when broken into pieces.

“Comparable with conventional plastics, our new supramolecular plastics are smarter as they not only retain the strong mechanical property but also reserve dynamic and reversible properties that made the material self-healable and reusable,” explained study author Dr Jingjing Yu.

Self-healing polymers are a promising technology with wide-ranging potential, and could in the future be found in car paint that repairs its own scratches, iPhone cases that fix themselves and next-generation batteries. The scientists believe using their approach to combine this property with easier degradability and recyclability opens up some exciting new pathways around eco-friendly supramolecular plastics.

“Emerging evidence has shown that LLPS could be a significant process during the formation of cell compartments," Li said. "Now, we advanced this bio- and physical-inspired phenomenon to tackle the grand challenge for our environment. I believe that more interesting materials will be explored with the LLPS process in the near future."

The research was published in the journal Angewandte Chemie.

Source: University of Turku