Windshield wipers are life-savers, but can also drive one to distraction with their incessant streaking and chattering. Well, the tyranny of the wipers may soon be over. McLaren Automotive’s chief designer Frank Stephenson has told The Sunday Times that the performance motoring company is investigating the use of "ultrasonic force fields" to replace windshield wipers in automobiles. While Stephenson referred to a military source for McLaren's tech, there appears to be very little public information on how such force fields might clean a windshield during a storm, so I'm taking a look at the patent history to see how this might be accomplished.

Windshield wipers have been around nearly as long as the passenger car. Invented in 1903 by Mary Anderson, the original was operated by a handle that extended through the windshield frame, and rotated a spring-loaded rubber wiper across the windshield. An interesting footnote to this invention is that it was aimed at electric cars, although the patent was broad enough to cover its use on internal combustion vehicles.

The concept developed through the years. In 1919, a windshield wiper system powered by engine vacuum was developed, although the function was taken over by electric motors in the 1960s. In the late 1950s, engine vacuum was again applied to operate the first intermittent wipers, in which mode the wipers were powered by air rushing into the vacuum stored in a small canister, and stopped when the pressure difference between the outside air and the canister became too small to power the wipers.

Patents aplenty

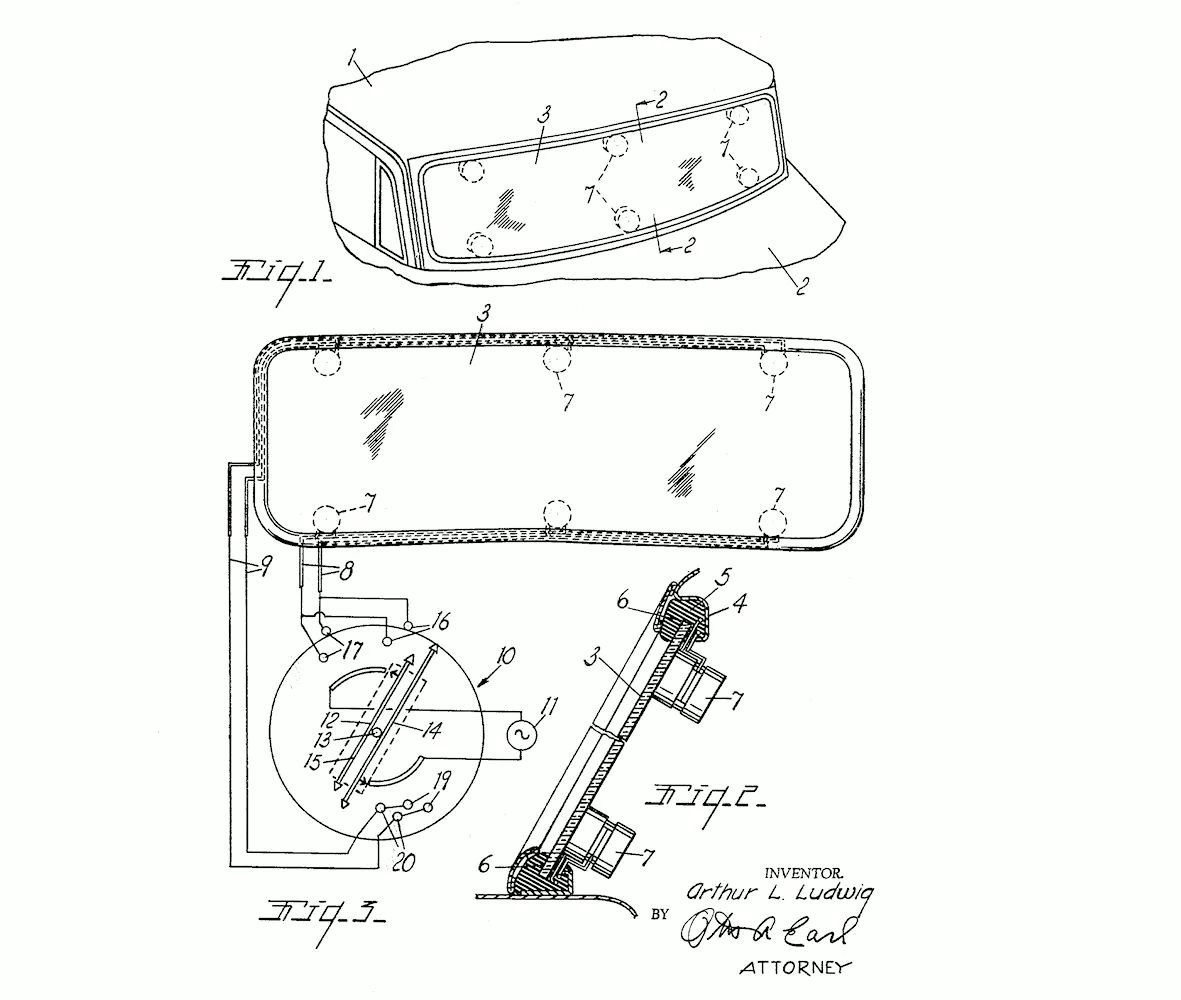

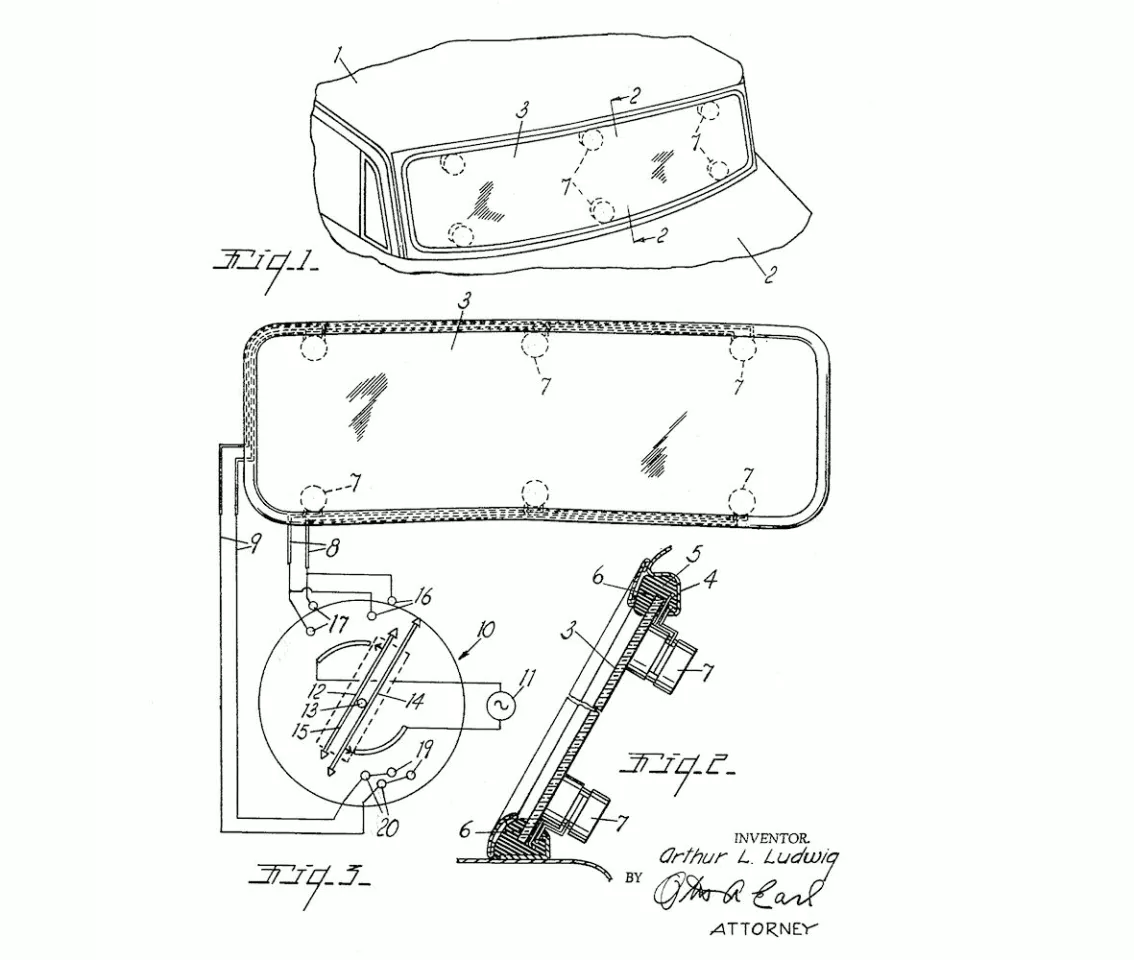

The concept of ultrasonic wiperless windshield cleaners can be tracked back to the early 1960s. US Patent 3171683 (filed in 1963) covers Arthur Ludwig's concept for a "Windshield assembly for motor vehicles and the like." (Patentese is such a fun language.) Ludwig was an inventor with a number of patents for various windshield wiper designs. This early design was basically an array of ultrasonic transducers fixed to the top and bottom of a windshield and driven by a high frequency oscillator.

Switching was arranged to give three modes of operation; top transducers only, bottom transducers only, and all transducers. The patent claimed that the different modes were suited for different conditions. In essence, the transducers shake the glass, so that rain, snow, mud, etc. do not stick. However, there appears to be no evidence that the concept was ever demonstrated – not an unusual situation where the utility of an invention is considered self-evident.

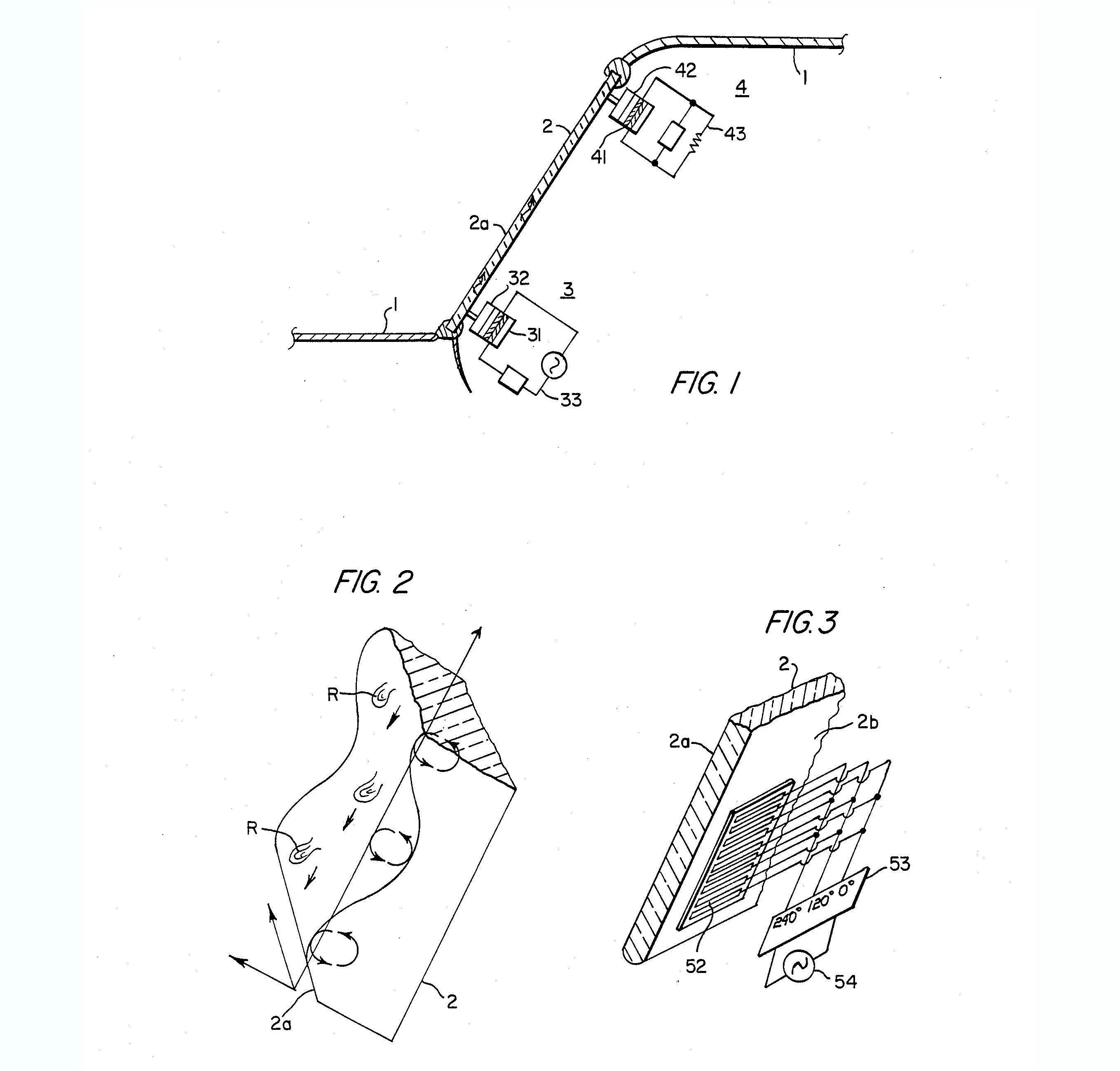

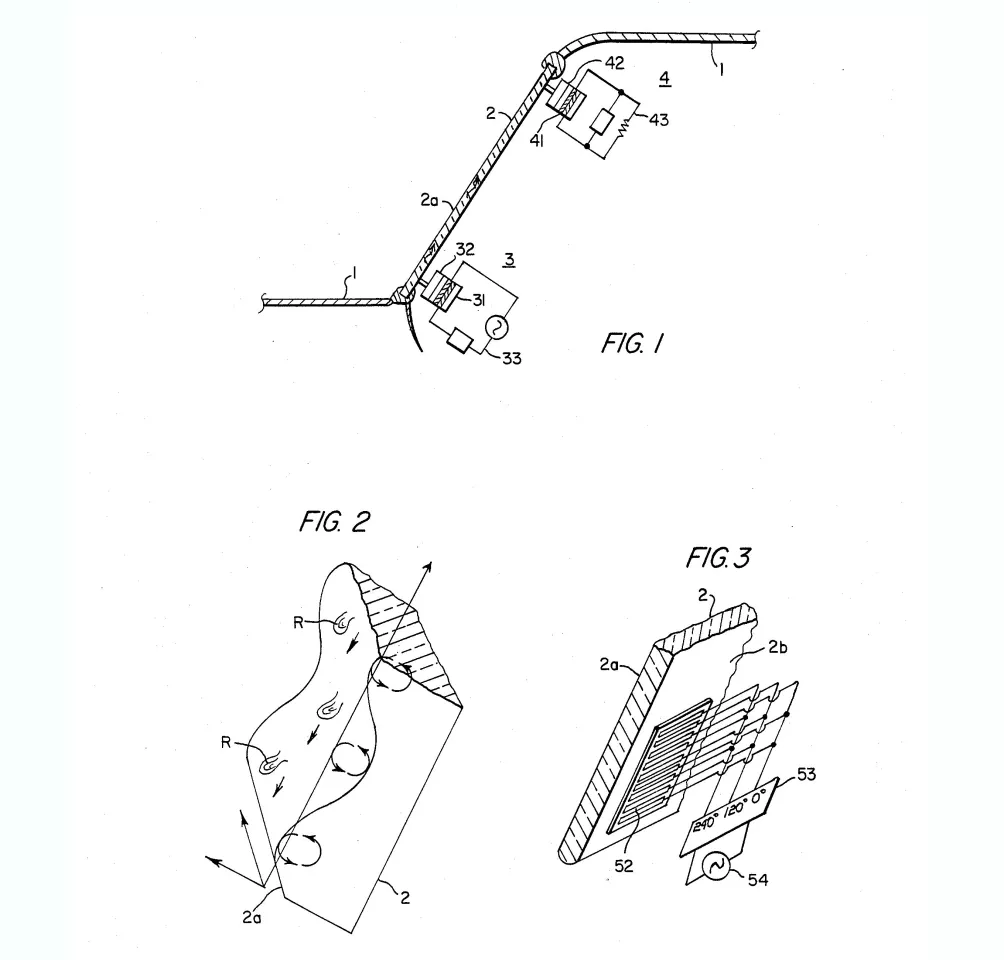

The next significant advance in ultrasonic windshield cleaners was made by Kenro Motoda. His approach, as recorded in US Patent 4768256 (filed in 1986), looks rather like Ludwig's, in that there are a set of ultrasonic transducers fixed onto the windshield. However, his transducers are actually launchers for surface acoustic waves. Unlike conventional vibrations, which generally produce a pattern of standing (stationary) waves on the surface of the glass, surface acoustic waves move the surface of the glass in an elliptical pattern that propagates across the glass, hopefully carrying along with it water, dirt, and other muck obscuring the driver's view.

While the progressive motion of the surface acoustic waves should be more effective than the simple shaking of the Ludwig design, it appears that Motoda's design was never produced.

A number of modifications of Motoda's basic design were patented over the years, including one that involved the piezoelectric polymer polyvinylidine fluoride being sandwiched between transparent conducting electrodes to generate the surface acoustic waves, (Broussoux et al, US Patent 5172024 (1990)); as well as applications to cleaning semiconductor wafers (Akatsu et al., US Patent 6021789 (1998)), and for shaking dust from camera optics (Urakami et al., US Patent 8063536 (2009).

The most recent patent I can find on ultrasonic windshield washers is WO2012095643, filed in 2011 by a small UK engineering firm, Echovista Systems Ltd. While the basic technique is still that of Motoda, the Trevett brothers (principals in Echovista) have expanded the possible modes of usage to include ultrasonic vaporization of precipitation from the windshield, the use of other vibrational modes which may be more effective in removing precipitation, using the heating of the windshield caused by the ultrasonic vibration to melt ice and snow and de-fog the windshield, and the use of a windshield washing liquid nozzle, having an effect similar to plunging the windshield into an ultrasonic cleaner.

Echovista also appears to have done significant testing on its ultrasonic washer, identifying maximum effectiveness is obtained with an ultrasonic frequency of about 2 MHz, corresponding to an ultrasonic wavelength of about 2.5 mm (0.1 in).

McLaren's options

What will be McLaren's approach to ultrasonic windshield washers? Well, it could do worse than buying up Echovista, as these seem to be the folks claiming the field as their reason for existence. Regardless, McLaren is likely to use some variation of the existing designs, as these seem to have pretty well covered the ground in terms of ultrasonic cleaning of glass.

Still, there are at least three variations that might increase the effectiveness and utility of ultrasonics. The simplest would be to constantly vary the ultrasonic frequency to insure that the wave couples well to a larger range of raindrop and snowflake sizes. Next in complexity is to make the ultrasonic generators capable of delivering an occasional shock wave; a pulse of very high intensity ultrasonics that would help dislodge recalcitrant clinging deposits on the windshield.

The ultimate version, however, would be to include phased array focusing of the ultrasonics within the windshield. If receivers for the ultrasonic waves are placed around the window, they can be used as a type of sonar to provide information on what is on the windshield. If there is a particularly obstinate lump (perhaps a bird dropping or a bit of sap on the glass), its location can be determined from the received data. Then the relative phases of the ultrasonic transducers can be set so that there is a huge spike of ultrasonic energy underneath the lump. This focused energy would allow the washer to remove befouling lumps that the washer globally lacks the energy to dislodge.

Summing up, it appears there are two approaches to ultrasonic windshield washers: brute force and cleverness. Given potential problems with longevity of the ultrasonic transducers, and the expense of high-power megahertz oscillators, it isn't immediately clear which approach will be chosen. However, as McLaren is not known for choosing low-tech answers, I suspect its solution will be on the clever side. The question is whether it will be sufficiently effective to pass all the local bodies that currently require windshield wipers on motor vehicles? Time will tell.

The video below illustrates how ultrasonic waves can clear a surface of debris. The good part starts at about 1:50.

Source: US Patents and Trademark Office