While medical electrodes are vital to the monitoring of electrical activity within the body, they're typically rigid and costly, plus they don't stay on well when the wearer is moving. A new sugar-cube-derived electrode, however, addresses those shortcomings.

Currently, the best-performing electrodes incorporate a conductive silver disc that makes contact with the skin. Because that disc isn't very soft or flexible, it doesn't conform well to the contours of the skin – this means it can be uncomfortable to wear, plus it's likely to fall off if the patient doesn't remain relatively still.

Additionally, the conductive gel which is applied between it and the skin tends to dry out quickly, resulting in a loss of signal if not frequently reapplied.

Led by Asst. Prof. Chuan Wang, a team at Washington University in St. Louis set out to develop a less expensive, more comfortable, better-adhering alternative, which would perform at least as well as existing electrodes. In order to so, they looked to regular store-bought sugar cubes.

Each cube was initially moulded into the shape of the desired electrode, after which it was dipped into a liquid polymer known as polydimethylsiloxane (PDMS) for two hours. That liquid was absorbed by the reshaped cube, making its way into the tiny spaces between the grains of sugar.

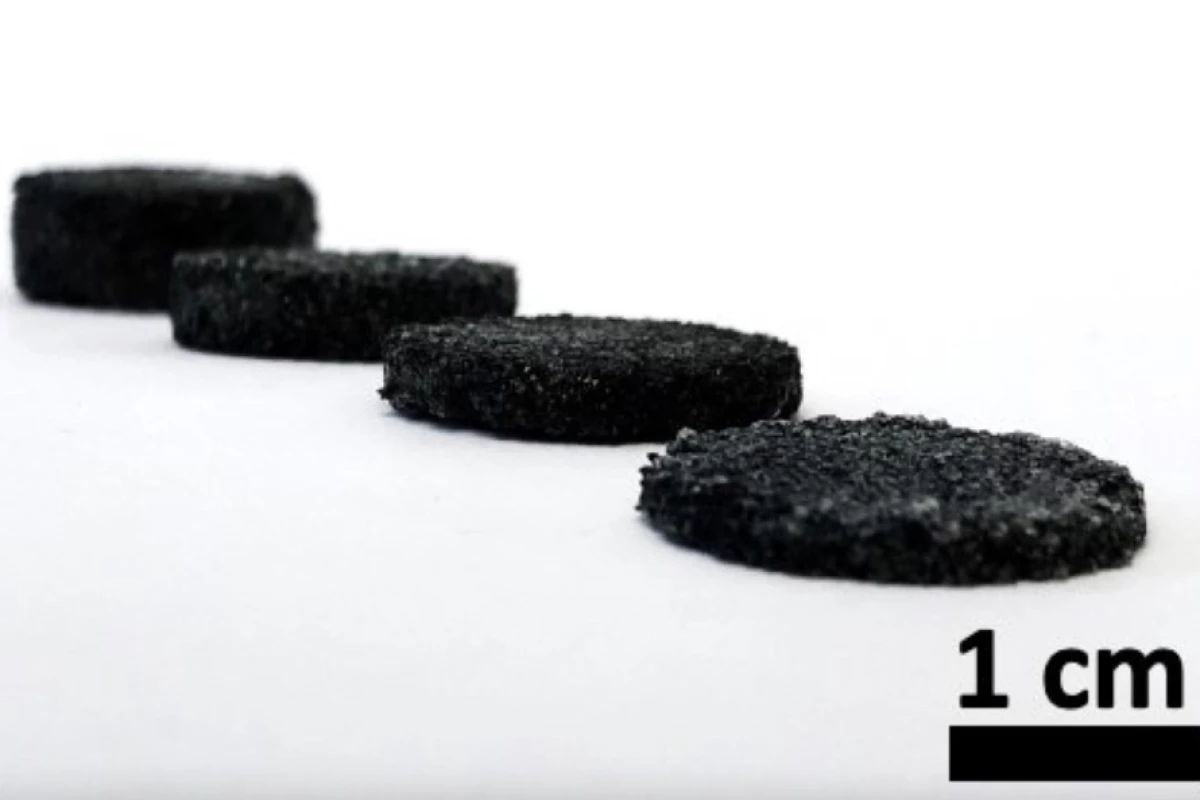

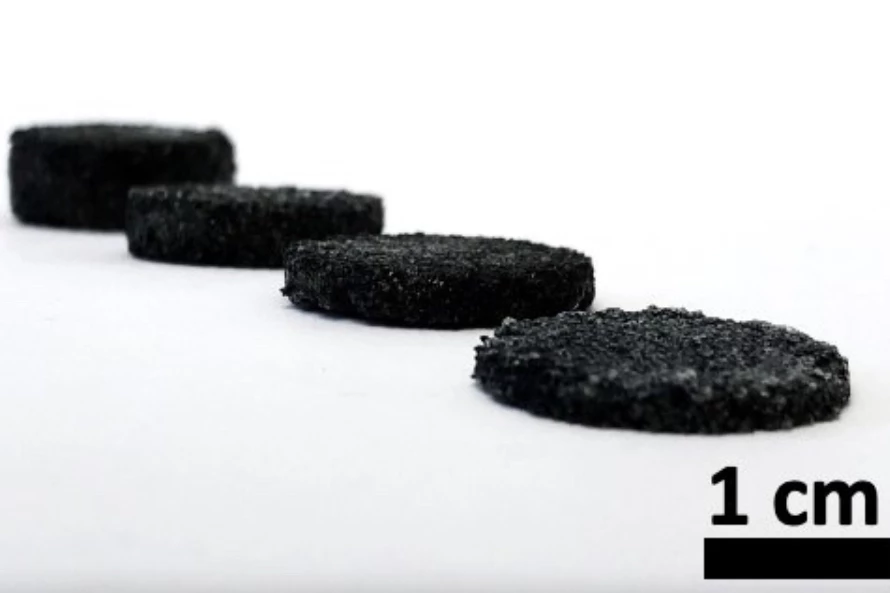

Once a three-hour hot-oven curing process had converted the liquid polymer into an elastic solid, hot water was used to dissolve the sugar, leaving behind nothing but a spongy, porous matrix of PDMS. After being treated with oxygen plasma and ethylene glycol, that sponge was dipped in another polymer – one that was electrically conductive – which formed into a thin film that coated the tiny pores.

Following another session in the oven, the conductive sponge was wired up and ready to be used as an electrode.

In tests performed on human patients, the device was found to conform and adhere to the skin better than conventional rigid metal electrodes. What's more, the increased surface area of its many micropores made for a stronger, less noisy electrical signal.

As an added bonus, because the sponge could hold a large amount of conductive gel, that gel didn't dry up as quickly as the thinner layer beneath a traditional electrode. The sponge's thicker layer of gel was additionally found to work sort of like a shock absorber, allowing the electrode to maintain electrical contract with the skin as the wearer moved around.

It is hoped that once developed further, the sponge electrodes could be used in medical examinations that require patients to perform physical activities, plus they could even be worn for extended periods by patients in their own homes.

A paper on the research was recently published in the journal ACS Nano.

Source: American Chemical Society via EurekAlert