If you’re into motorcycles, you’ve most likely heard about the likes of Nissin and Showa. They’re two of the most well-known motorcycle parts manufacturers and, coincidentally, both of these companies come out of Japan. But only a select few among you would have heard of Hitachi Astemo – the parent group of both companies.

Both Nissin and Showa joined forces to introduce an exciting new development at EICMA at the end of last year: an integrated front fork and brake caliper system. With so much happening at the motorcycle event back then, this eye-catching concept may have gone unnoticed, but it would be a crime to overlook its potential advantages and use cases.

All the bikes produced today come with either axial calipers (on more affordable models) or radially mounted calipers (on more expensive, newer models). Both axial and radial calipers are attached to the fork, perpendicularly in the case of axial and parallel in the case of radial. Neither of these setups has the caliper directly fitted to the fork.

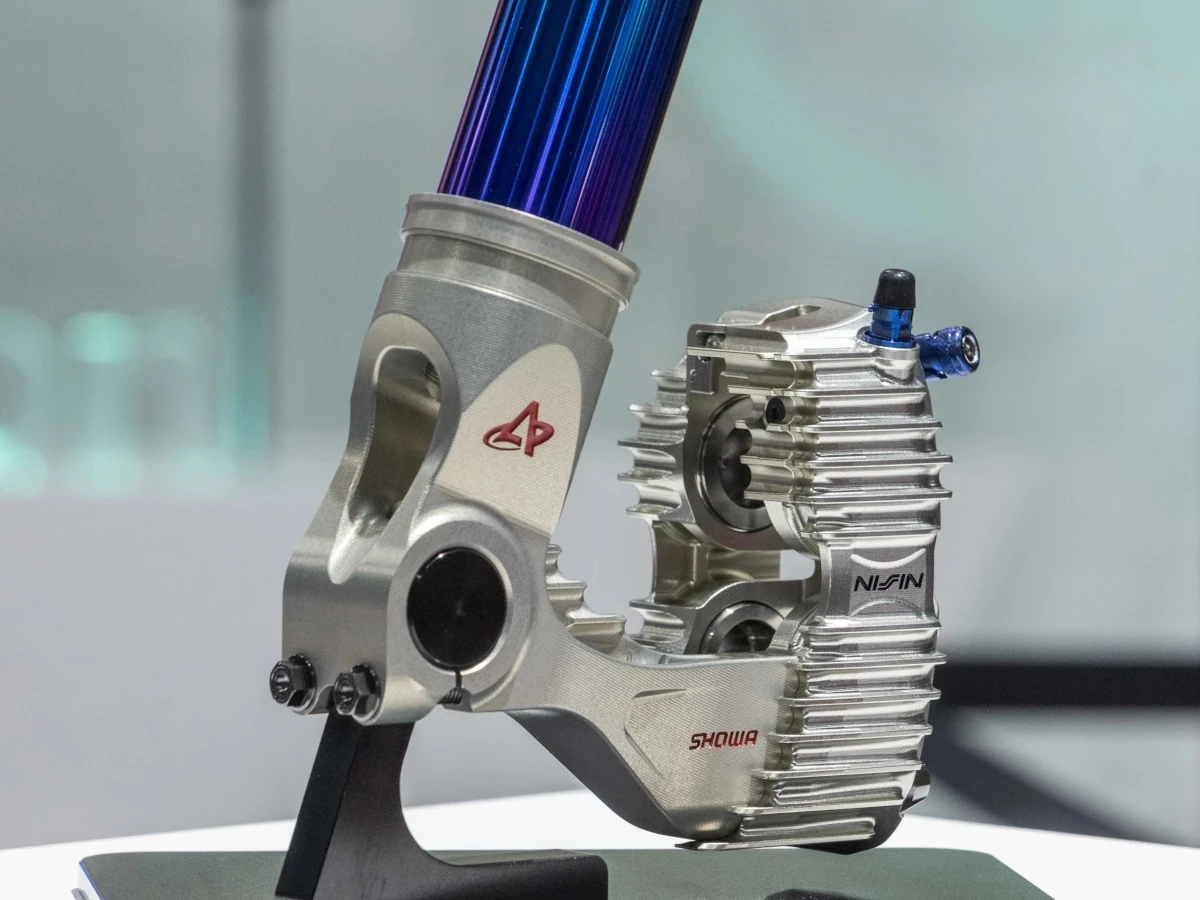

That’s exactly what Nissin and Showa’s latest design does. This collaboration offers a fresh take on "functional coordinated design," in which the caliper and fork blend together harmoniously, something previously unheard of in motorcycle design.

As reported by VisorDown, in this combined fork and caliper design, both the caliper and the bottom of the fork leg are machined from a single billet. This helps increase the contact area between the caliper and the fork axle support by 30%. And there’s more than one benefit of this revamped design.

First and foremost, it increases rigidity. Under extreme braking, traditional setups frequently experience flex, which impairs performance. Showa and Nissin assert that their novel approach offers better stability while in use, thanks to the increased surface area where these parts meet.

Maintaining ideal brake temperatures is crucial for reliable performance on the road and racetrack, as any experienced rider would know. Improved heat dissipation is the next notable advantage of this integrated fork and caliper system.

Compared to conventional mounting systems, the design enables a more efficient flow of heat away from the braking components. This improved thermal management function is expected to result in a notable drop in caliper temperature by as much as 5%.

I’m an advocate of light is right when it comes to motorcycles. That’s because every gram matters when you’re on a bike. Reducing the weight directly improves handling qualities without compromising durability or strength.

That’s the next biggest advantage of this system. Compared to traditional radial-mounted systems, Showa and Nissin's integrated design promises a weight savings of at least 200 grams!

But all that is in theory. In practice, there are some concerns about this design’s viability for daily use. First, in contrast to conventional setups where calipers can be removed independently of the fork legs, the integrated setup will likely add effort and time (and money) in servicing.

When the time finally comes to implement this new tech in production models around the world, the real test will ultimately be user experience. But I personally think Hitachi Astemo will first offer this system on race models before folks like you and me get our hands on it.

But a lot of things have to go right for it to come to that stage. Not forgetting that pricing will be a vital factor too. If everything goes according to plan, we might well be looking at a brand new way of braking on our motorcycles.

Source: Hitachi Astemo via VisorDown