NSK is one of those companies that makes products that you use every day, but that are are buried somewhere within another company’s product, and you’ll never know the century-old Japanese giant was responsible for the design and manufacture of those internal parts.

NSK has produced bearings for 97 years and holds the third largest share of the vast global bearings marketplace – bearings of every conceivable type, with your car most likely to carry an NSK product (a typical car has between 100 and 150 bearings in areas such as the crankshaft, camshaft, transmission, drive train, wheels and suspension and NSK holds the greatest share of the global automotive marketplace), though NSK’s bearings are also likely to be found ensuring the key moving parts of domestic vacuum cleaners, washing machines and dishwashers endure as little friction as possible.

NSK also makes big bearings, such as those in the wheels of the Shinkansen (Japanese Bullet train) and in the rotors of industrial wind turbines, while at the other end of the scale, it makes miniature bearings for high speed applications such as the 400,000 rpm required by a dentist’s drill. It produces both miniature bearings with a bore of just 1 mm to colossal bearings with a diameter of five meters.

The company’s tale is an interesting one because it illustrates how a commitment to one product category can see a company develop far reaching research and development capabilities that are relevant to and subsequently influence many industries.

NSK produced Japan’s first bearings, first automotive bearings, first steam train bearings, first aircraft bearings, first jet engine bearings, Japan’s first ball bearings with non-contact seals … the list is endless.

Towards this end of the twentieth century, many of the company’s Japanese firsts became world firsts – the world’s first sealed clean roll-neck bearing for steel rolling mills, the world’s thinnest drawn cup needle roller bearings for drive wheel with built-in ABS sensors and so on.

If you think about all the world's machinery that requires bearings, and the rate of development of that machinery, then of NSK’s specialist role in providing bearings of all kinds, it is not surprising that it has developed core competencies in tribology, materials science, analysis and simulation technologies and mechatronics in meeting the constant challenges from the design engineers of the world’s manufacturers. Its 121 global sales offices carry 220,000 plus different parts and it has 64 production plants producing more than three million new bearings a day.

So perhaps by design, perhaps by providence, NSK’s raison d’etre evolved over the decades and subsequently became focused on “responsive and creative motion and control” and in so doing, unknowingly destined itself for the robotics industry – ironically, an industry that had not been conceived when the company was formed in 1916.

NSK's robotics development

NSK’s participation in the last three IREX exhibitions has been interesting to watch. Beginning with a showing in 2009, NSK decided to focus its initial robotic development in the area of empowering the visual impaired, and given the prevalence of such impairment, this could eventually be of significant societal benefit.This study identified that in 2007, visual impairment affected more than 1.64 million people in Japan and cost around JPY8785.4 billion (US$72.8 billion) across the economy, equivalent to 1.7 percent of Japan's gross domestic product.

Community care to people with visual impairment was one of the largest components of this cost and with the Japanese population being one of the longest living and the oldest in the world, the development of guide robots makes a lot of sense, particularly considering that Japan will have commercialized its expertise by the time other countries need to support their aging populations.

At its first outing for the guide robots at IREX in 2009, NSK showed the NWR001. It was large and although its weight and size was never mentioned, you can be sure the initial platform was far bigger and heavier than the 40 kg (88 lb), 520 x 660 mm (20.5 x 26 in) NWR002 which emerged two years later. It was however, an important first step towards creating an autonomous mobile robot to substitute for the seeing-eye-dog and wheelchairs.

At IREX in 2011, much of the attention was focused on the company's technologically-dense robot guide dog. NSK decided to do an advanced canine variant because the four-legged platform offers a more familiar interface and by virtue of its advanced voice recognition and synthesis, far greater capabilities.

Real guide dogs are costly to train and keep, and cannot be used in a wide range of living scenarios, particularly in special homes for the aging where dogs are often banned on the basis that they potentially introduce bacteria and the risk of disease.

The guide dog robot was designated NR 003 and had voice-recognition and voice synthesis, so it could be instructed verbally as a guide dog would be, though the female voice it produced to respond to its master was quite disconcerting and probably in need of further development.

The NR 003 had a configuration never before seen – it featured two wheels on each of its four legs and those wheels could be locked and driven in both directions depending on the need for stability and motion, with an array of proximity sensors in each of its four feet to confirm the touch down of each foot on a stair, and the proximity of the next stair.

It could climb previously unknown stairs due to its automated recognition, and had a link harness of continuously variable height that enabled it to guide vision-impaired people both up and down stairs with a high degree of surety. I watched the demonstration several times, and it was very impressive for a first attempt, if a little slow and ponderous. It looks to me that it will be ready for commercialization well before the target date of 2020. The far-less technologically prodigious NWR002 prototype was overshadowed by the guide dog on the NSK stand that year. The relatively simple NWR002 guide robot, at least by comparison to the fascinating complexity of the NR003, will be much cheaper to produce than its four-legged stablemate.

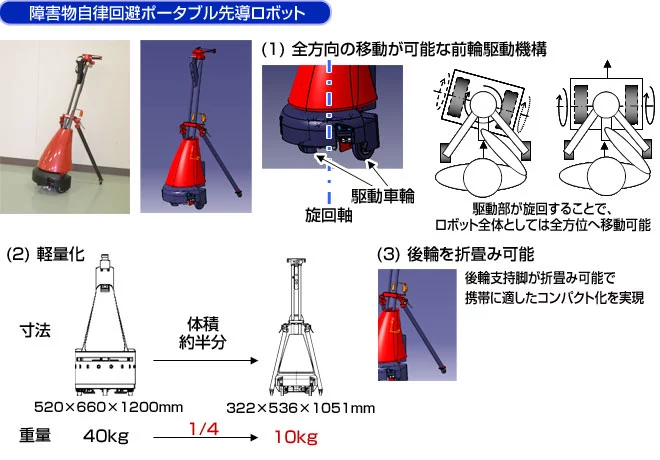

Although the NWR002 can't take a user up and down stairs, it provided a sound basis for the Lighbot, a far more affordable and accessible solution for mass production. It did have improved obstacle avoidance capabilities, which recognize stairs and avoids them, and also contained an improvement on the NWR001's stability enhancing capabilities, despite its drastic weight loss.

This year a commercialization-ready Lighbot (360 x 450 mm/14.2 in x 17.7 in and 15 kg/33 lb) Lighbot was introduced which can guide visually impaired people around like a guide dog, but only in two dimensions (no stairs) in environments such as a hospital or nursing home or rehabilitation or palliative care facility. A prototype of a lightweight Lighbot (320 x 540 mm/12.6 x 21.2 in and 10 kg/22 lb) was also shown at IREX 2013.

That’s a 75 percent weight reduction and an 83 percent footprint reduction in 24 months.

The reduction in weight of both Lighbots shown in 2013 has been achieved by adopting and leveraging the advantages of front wheel drive and adopting a CFRP (carbon fiber reinforced plastic) body.

The further weight reduction of the prototype leverages the front wheels drive by using a simplified, and much lighter rear stabilizing structure, and by moving most of the working parts downwards.

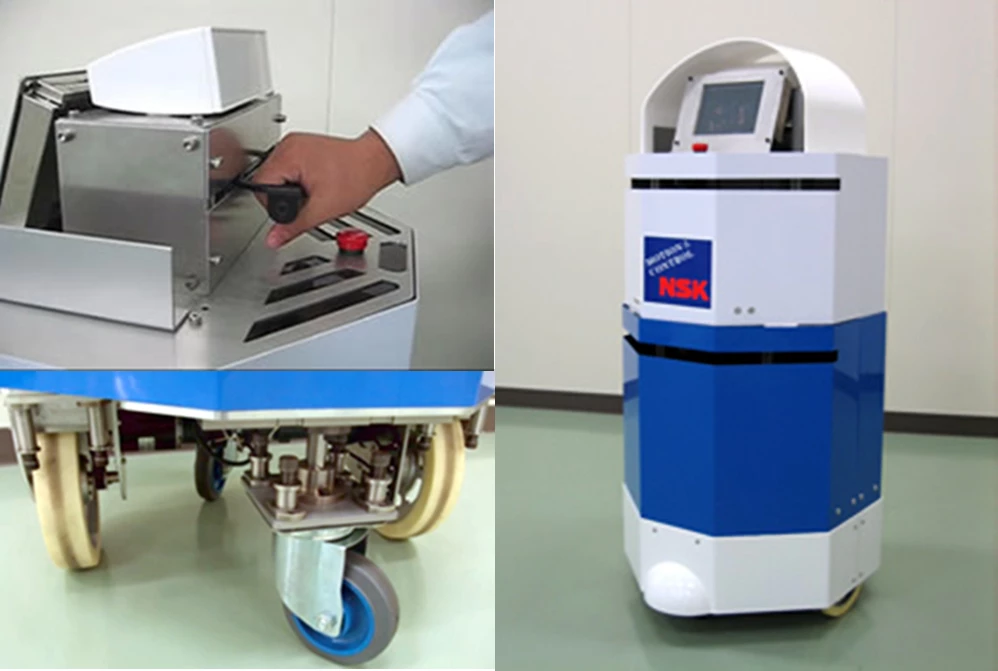

The ingenious right-or-left-hand drive interface of 2011 has been both replaced and improved, and all other aspects of the robot’s awareness and capabilities have remained equal or become better than the original.

That's the 2011 drive interface above, with my meaty paw aboard, and the 2013 version below.

The original drive was really easy to use, twist to go left or right, push or pull for forward and back, and it didn't matter whether you were left- or right-handed. The 2013 version used a similar set-up with a different handle, and will be even easier to use because it is easier to grip than the clamshell.

The new Lighbot now also detects obstacles not just on the floor in front, but in the area above the waist for low hanging obstructions. It also builds its own environmental map, enabling it to become more confident over time.

In the evolution of the Lighbot, NSK has achieved a game-changing weight and footprint reduction, and at 10 kg, the lightweight Lighbot prototype can now be easily carried and stored. The world's lightest transport appliances, such as Toyota's Winglet, Honda's original U3-X and the Yikebike, are all in the same weight class ... and they are for people who definitely need both eyes open.