Earlier this year Rolls Royce outlined a future where giant robot cargo vessels ply the world's sea lanes without a human crew on board. That scenario is now coming closer to reality as the EU project MUNIN looks into the feasibility of robotic freighters and the hurdles they must overcome.

Project MUNIN is made up of eight partner companies led by Germany’s Fraunhofer institute and coordinated in Sweden. Meanwhile, the Scandinavian research organization SINTEF, though its Marinitek subsidiary, has invested NOK12 million (US$1.8 million) in the project. MUNIN’s task is to identify the factors that will go into automated freighter operation, the challenges and obstacles involved, and the best way to make the changeover from manned to unmanned shipping.

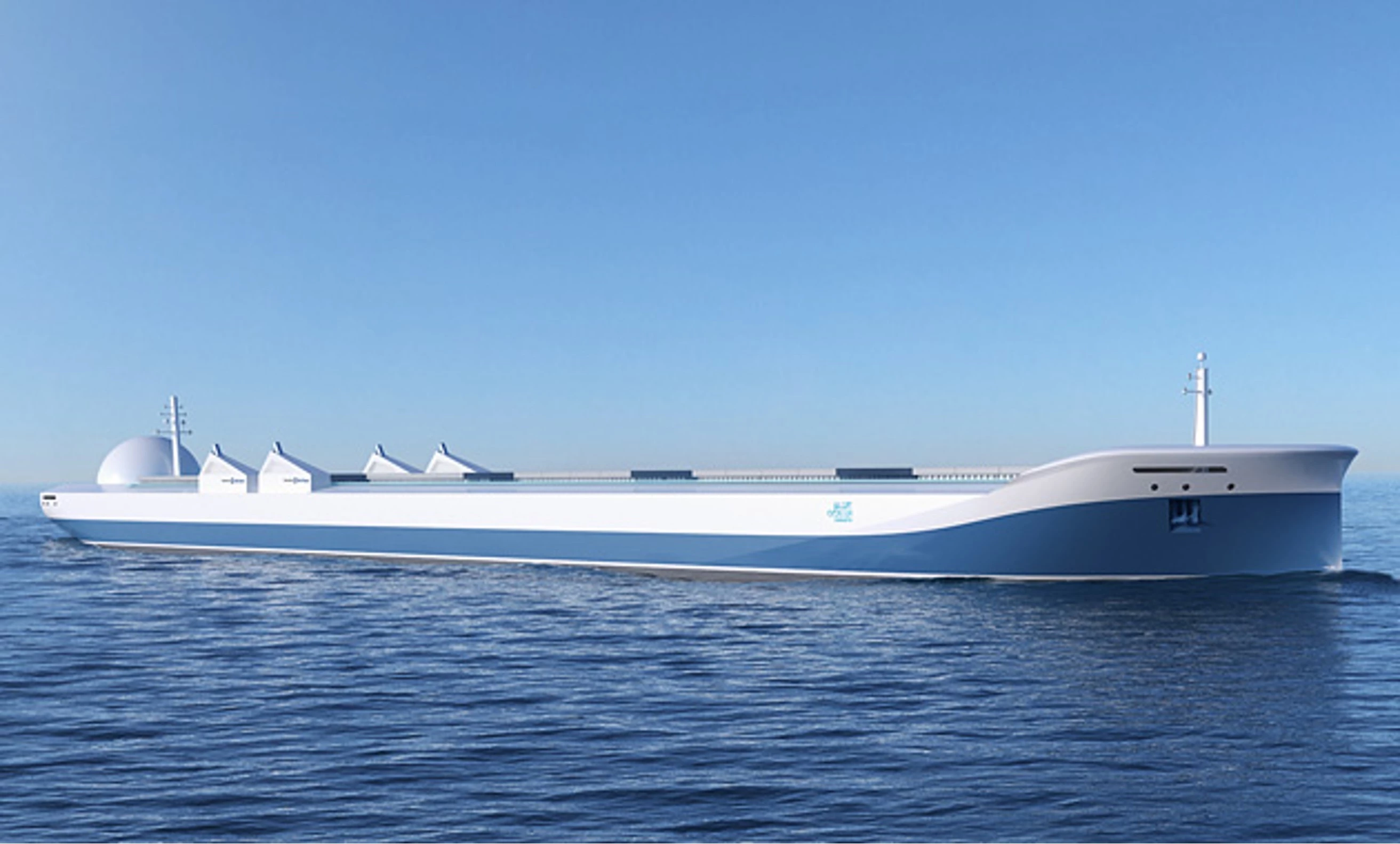

SINTEF sees a time within twenty years when 200 m (660 ft) robotic cargo ships will be a reality. According to the organization, there are over 100,000 merchant ships steaming between the world’s ports with more launched every day to keep up with the growing demands of trade. The problem is that these ships are becoming increasingly difficult and expensive to operate. Not only are labor costs the highest single expenditure, but fewer and fewer people are willing to sign up for spending a fortnight at sea with nothing to look at but waves and seagulls.

Another problem is safety with human error contributing to an estimated 75 percent of maritime accidents. Add in the growing changes in the economics of shipping, the ever-climbing price of fuel, and new environmental regulations, and automation becomes a very attractive option.

But shifting to automated shipping is not like in an old Star Trek episode where the mad scientist plugs a supercomputer into the USS Enterprise and Captain Kirk is left to twiddle his thumbs. Rather than simply swapping out crews for robots, the specific tasks, the machinery needed to carry them out and the rules they must operate under must all be examined in detail.

Think of it as being a bit like the development of robot vacuum cleaners. Instead of a mechanical person wearing an apron and big white gloves pushing a hoover about, they evolved in the form of a giant motorized hockey puck. Rather than vacuuming the rug on the typical human schedule where a month’s worth of dust is sucked up at one go, they clean the floor every day, needing to collect only a tiny tray’s worth of dust at a time.

It's a similar process with robotic ships. For example, a robot ship works better at slower speeds because by reducing speed from 16 to 11 knots it provides more time to detect and avoid hazards. In a manned ship, the loss of time would cost a fortune in wages and disgruntled sailors, but SINTEF says that in a robot ship it not only means greater safety, but 50 percent fuel savings, and lower emissions, and a week's more travel time is offset by savings in wages. But to make this works means organizing things so that the same volume comes in at a constant rate, so travel time is irrelevant.

It's these sort of challenges that project MUNIN is intended to sort out. SINTEF believes there's a need to change the regulations, which are all based on the premise that there’s a crew on board. In addition, engineers need to demonstrate that current and forecastable technologies are up to the job and make a case that will convince the maritime authorities.

Part of making this case is the need for accurate enough sensors and intelligent enough computers to detect and avoid flotsam or other vessels, and that ability to provide constant status monitoring and satellite communications. This is being studied for the project by a Norwegian team, who say that a 3 to 4 Mb broadband connection is enough to provide onshore control of a vessel.

Another aspect is safety. One way of improving this is to operate the robotic ships at slower speeds. In addition the first robot vessels should also avoid high-priority cargoes, like smartphones or cars, or potentially dangerous cargoes like petroleum or raw cotton. According to SINTEF, these vessels will be restricted to carrying ore or grain.

Necessary changes to existing regulations include as right of way in sea lanes, so an unmanned ship can more easily deal with them. But the biggest problem is reliability. Robotic ships need to be able to operate for two or three weeks at a stretch without maintenance. One way to handle this would be to change from the heavy fuels now used aboard cargo ships for more expensive lighter fuels or even natural gas, which would allow for engines that need less attention.

Project MUNIN is based on the fact that much of the technology for robotic ships already exists. Many ships have anti-collision systems, automatic steering, satellite navigation, ship-to-shore telemetry, onboard cameras, so the leap isn't so great as one might think. But instead of just cracking a bottle of champagne on SS Roboship, the technology would be introduced gradually, such as reducing watch crews or allowing the entire crew to sleep at the same time without anyone on the bridge. Much of this involves simply installing new technology on existing ships, but over the next twenty years it will require redesigning ships from the keel up to get the most out of autonomous systems.

In addition, SINTEF sees the technology has having broader applications as it matures. These may include aquaculture, the offshore wind and subsea sectors, oil and gas production and mineral exploitation. However, the organization points out that even if robot freighters become a reality, they won’t be steaming from dock to dock because automation isn't a panacea. It may be a way of saving money at sea, but they’ll need to pick up a human pilot for getting into harbor because a workable robotic solution is still likely to be more expensive for that task.

Source: SINTEF