Data storage and preservation are no longer restricted to the needs of individual users, or even of companies or governments large and small. Instead they are the only remaining approach to preserving the history associated with the evolution of the digital age, and possibly the post-human era to follow. A research team headed by Prof. Min Gu of Swinburne University of Technology has developed a new data storage method that may be of considerable use for such civilization-sized concerns by putting a petabyte of information on a DVD-sized polymer disk.

Big data presents today's and tomorrow's world with a wide array of possibilities and difficulties. Cautionary tales are already spreading across the world's newspapers. Estimates suggest that there is nearly a zettabyte (a trillion gigabytes) of digital information stored in various places on and off the Web. Digital recordings of all US phone calls for a year are estimated to require 0.3 zettabytes.

It is crucial that the information in the world's databases be protected against accidental failure or malicious erasure. Leaving this problem to the semi-mystical cloud seems asking for trouble, whose only possible helping size would be extra-large if hackers turned the cloud on its head one fine afternoon. But how is civilization supposed to address this need? A stack of Blu-Ray discs containing a zettabyte would be about 24 km (15 mi) high. Solid state drives or hard drives would take up somewhat less room, but would cost far more. How can we insure the data survives?

An ingenious approach to data storage with one particularly clever bit has emerged from research carried out by researchers from Swinburne University of Technology and the CSIRO in Australia. Their new approach offers the potential to place one petabyte (not one terabyte) on a DVD-size disk. Our zettabyte archive would then fit on a thousand disks, resulting in a stack standing just over a meter in height.

In an article published in the June 19, 2013 issue of Nature Communications, the research team describes how to reduce the spot width for optical recording within a plastic layer from Blu-Ray's 130 nm width to a width of only 9 nm, which is about one percent of a single wavelength of light.

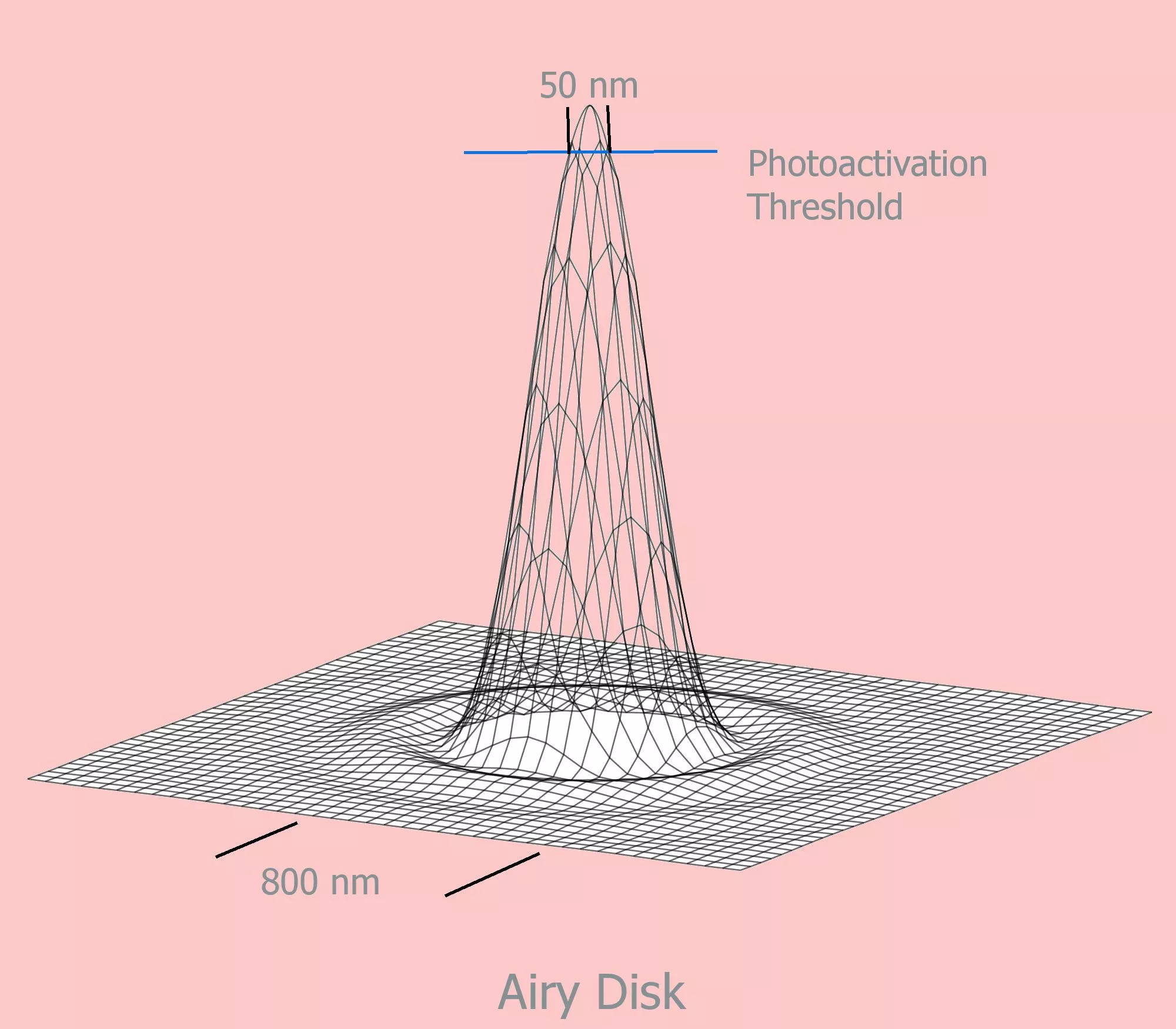

Why couldn't Blu-Ray technology have accomplished this, instead of having a spot width about one-third the size of a single wavelength? The problem is a fundamental property of light, which may have been first discovered by Ernst Abbe, an optical physicist and one of the founders of the Carl Zeiss optical company. His experiments with lenses in the latter third of the 19th century demonstrated that light having a given wavelength cannot be concentrated into a spot (the Airy disk) smaller than about one-third of the wavelength. As Blu-Ray uses a blue laser with a wavelength or 440 nm for reading the optical disk, this explains the Blu-Ray spot width of 130 nm.

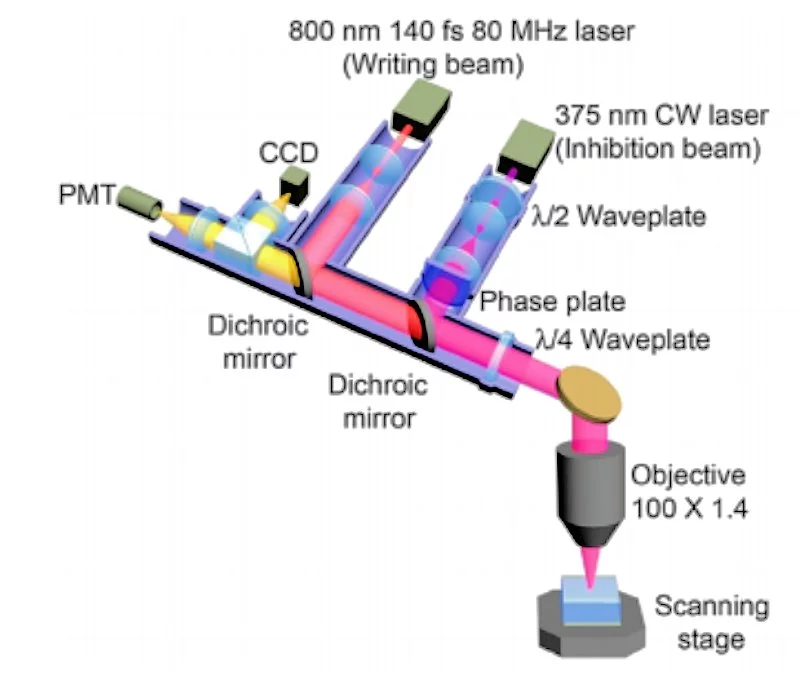

The Australian researchers avoid the Abbe limit by their development of a new organic polymerization catalyst that possesses two different reactions to light. An 800 nm laser light causes this catalyst to break apart into polymerization activators that, when present in sufficient numbers, cause a monomer to polymerize. However, a 375 nm laser light directed onto the same catalyst releases polymerization inhibitors that prevent a monomer from polymerizing. Roughly speaking, if there are more activators released, the monomer turns into plastic. If more inhibitors are released, the monomer does not react.

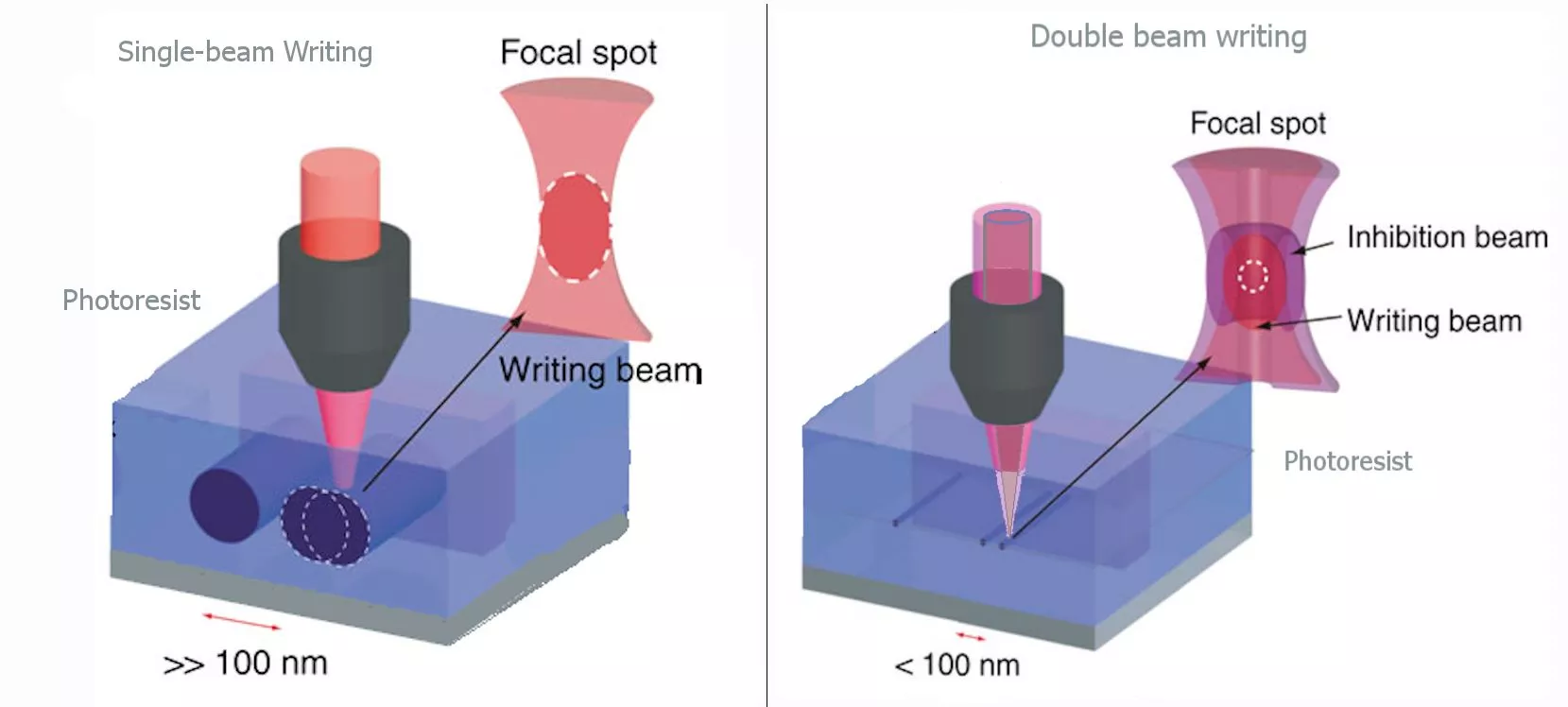

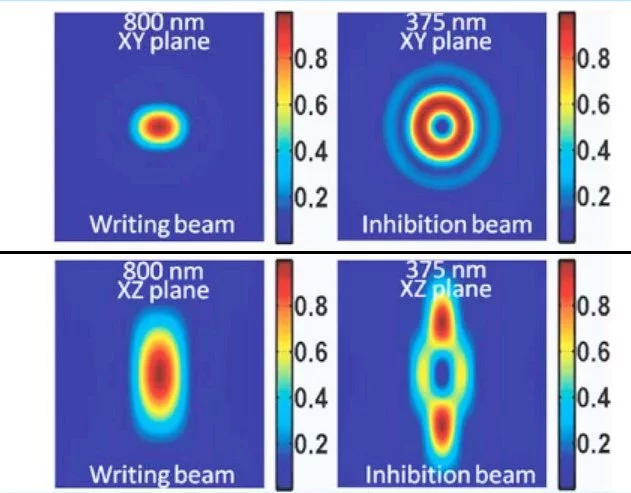

To write a feature smaller than the Airy disk into the light-sensitive photoresist material used for photolithography, first direct a focused 800 nm wavelength laser beam onto the unpolymerized storage medium. This light causes the photoresist to polymerize where the intensity of the light is sufficiently large to release the polymerization activators. To release enough activators, the light intensity must be above a threshold value, with the polymer spot size becoming smaller as the peak intensity of the 800 nm light is reduced.

At the same time, direct a 375 nm light on the same focal point, so that the activators and inhibitors are in rough balance throughout the Airy disk. In this case, no polymer will form. Now comes the tricky bit. Alter the the 375 nm laser light into a donut-shaped mode.

Earlier we saw that the 800 nm light alone can polymerize a spot having a diameter of roughly 100 nm. However, by inhibiting the outer portions of that spot with a donut-mode 375 nm light, the photoresist in the outer portion of the focused spots of light will not polymerize. This allows the formation of polymer spots as small as 9 nm in size, a value that seems to represent how far the activators can diffuse from a point source in this monomer.

Rather than the smaller polymer spot size coming about through some sort of destructive interference of the two laser beams, the two different laser colors individually induce competing chemical effects. Control over this chemical competition is what produces the small polymer features.

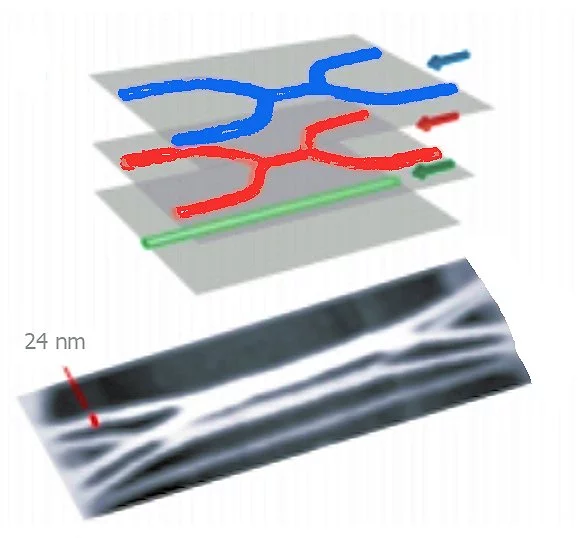

Given the recent rapid development in 3D printing, any scannable selective polymerizing apparatus must also be thought of as a fabrication tool. The Australian researchers took the additional step of demonstrating the ability of their new photopolymerization principle to form tiny 3D objects. The photo above shows a 3D stack of what could be integrated optical elements, two being optical coupler/mixers and the third being a simple waveguide. The scale of the image is about 500 nm by 1500 nm, clearly pointing out the subwavelength scale of the fabricated structures as well as the ability to produce plastic structures at varying depths.

Clearly this new approach to data storage and formation of few-nanometer scale structures is not yet ready for primetime. There are several levels of development which remain on the way to new standard commercial products. The promise of those potential products is significant enough that this may well be the start of something big.