Construction robots have been around for a while, automating challenging tasks on job sites. The new kid on this block is called Charlotte, and it's billed as being autonomously capable of building a 2,150-sq-ft (200-sq-m) home in a single day – operating at roughly the speed of 100 bricklayers.

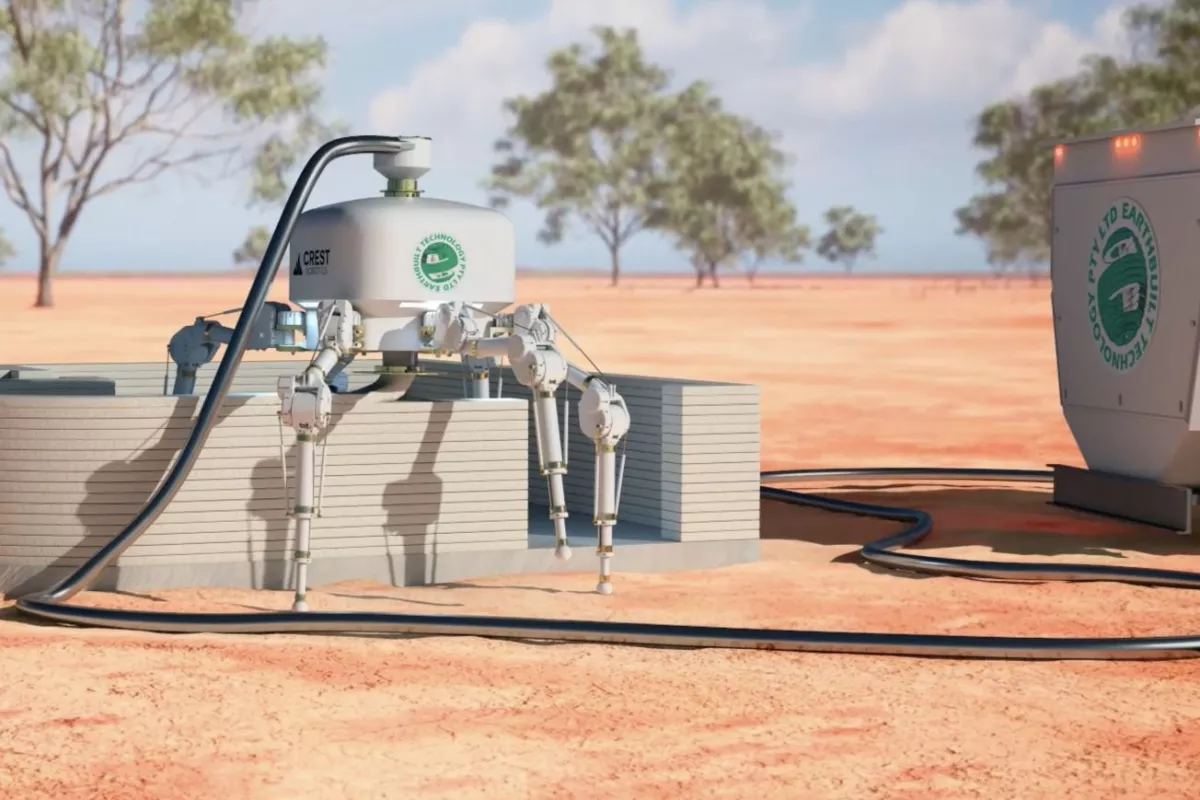

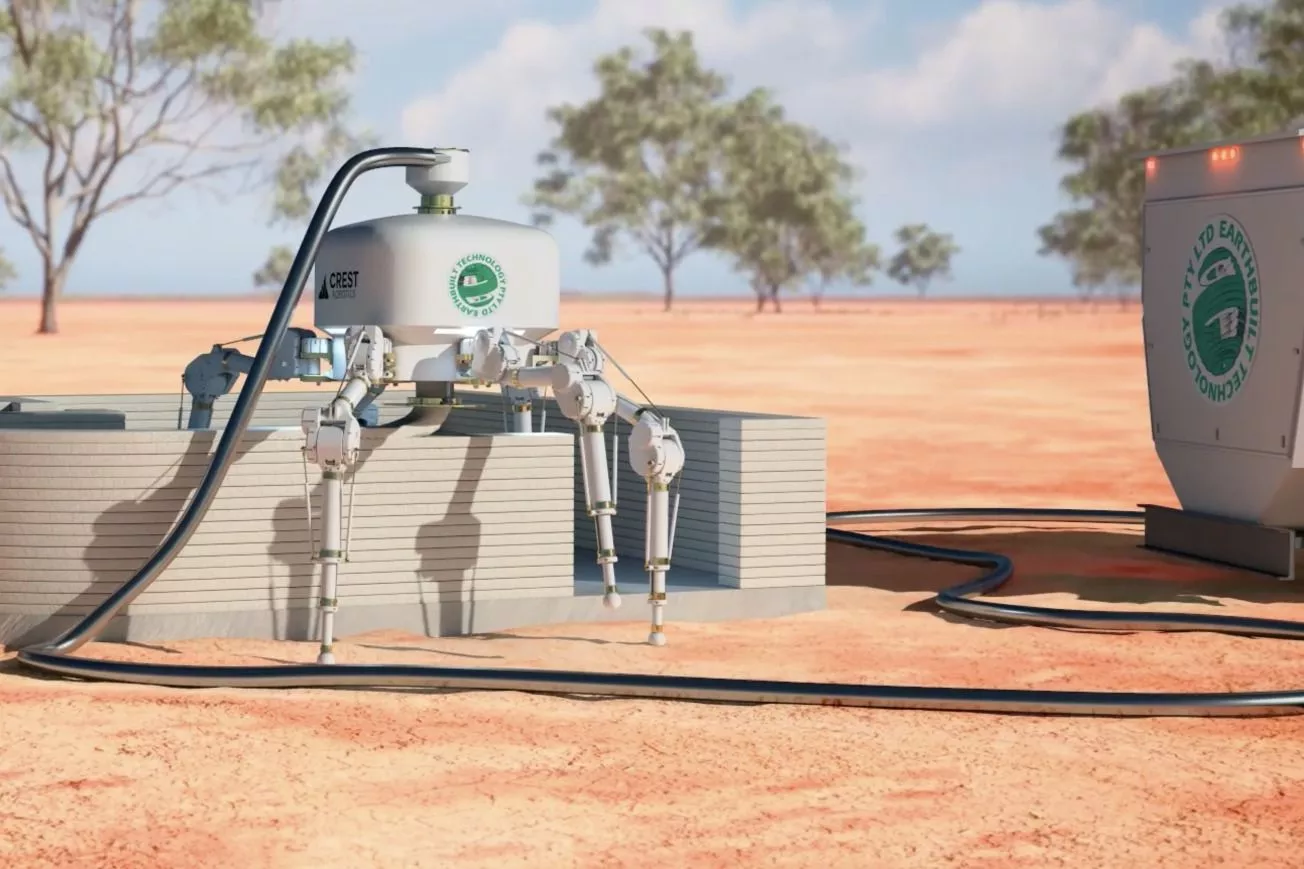

Charlotte is the result of a collaboration between Australian engineering startup Crest Robotics and Earthbuilt Technology, which has developed a locally-sourced, eco-friendly raw building material made from sand, waste glass, and crushed brick.

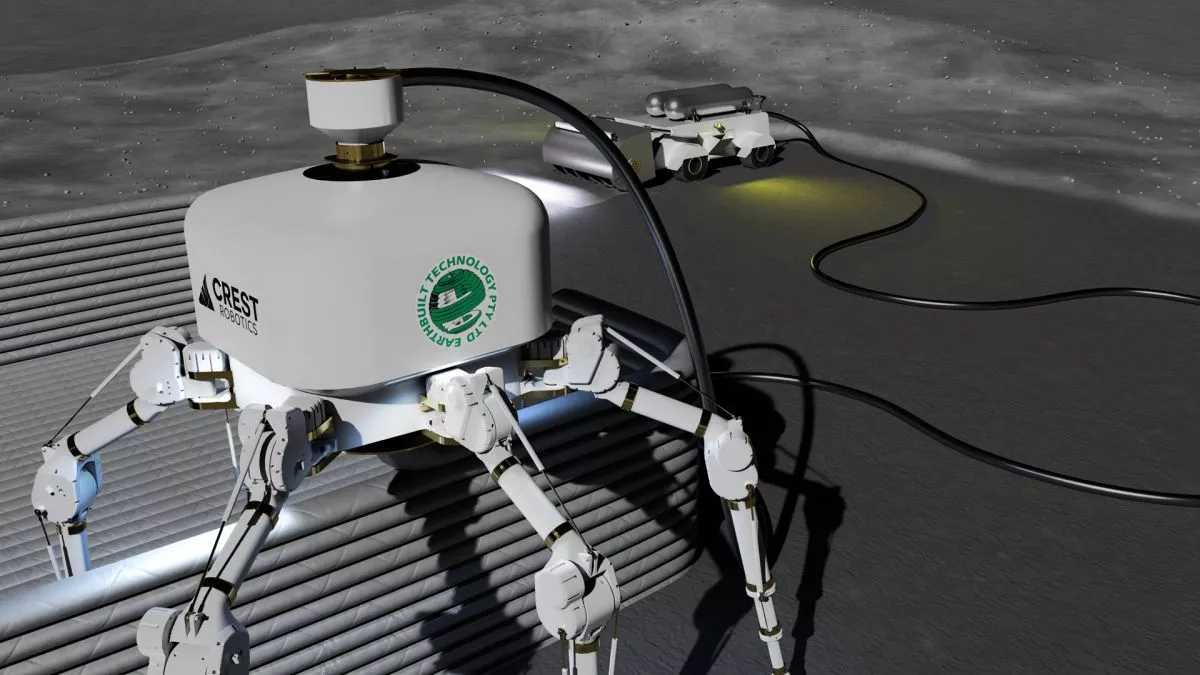

Rather than individual tasks involved in complex structures like tying rebar and assembling wood panels, Charlotte uses an extrusion system to 3D print the aforementioned compressed building material in successive layers on its own – moving along and raising up on its spider legs. It all happens in one machine in a single process.

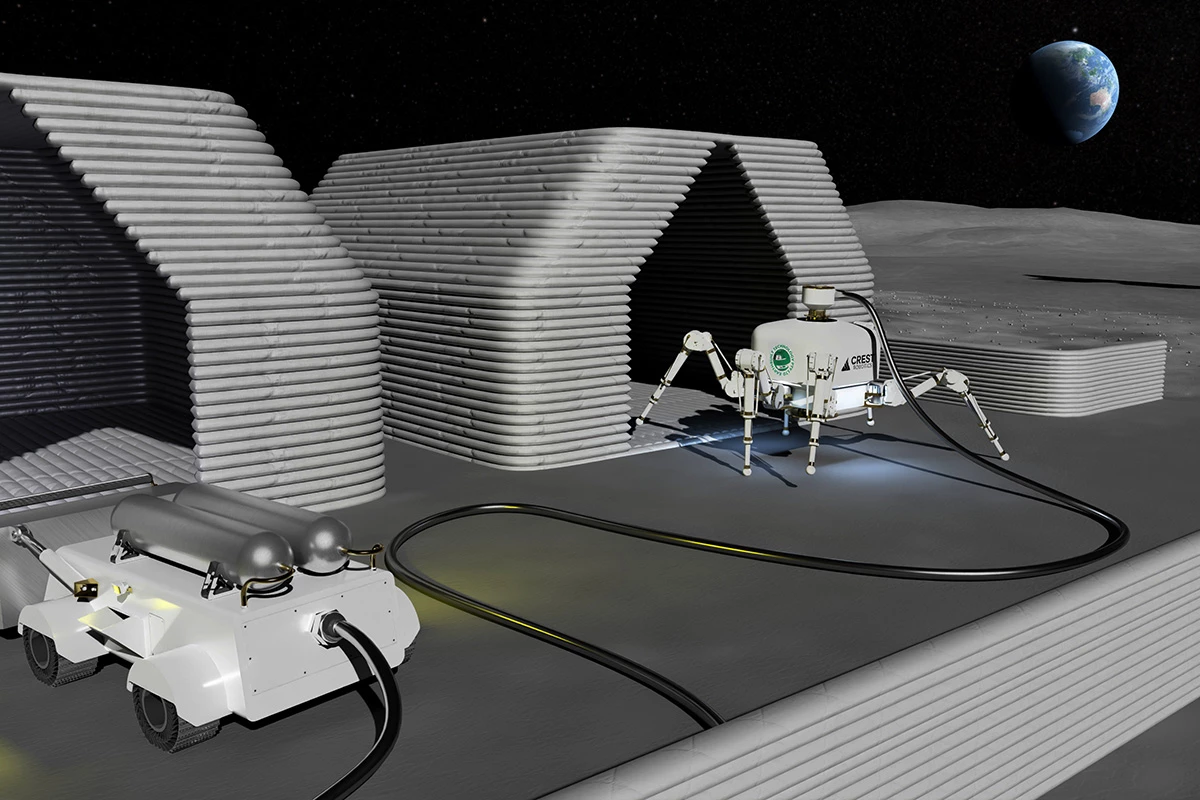

The bot is still being developed, and is likely years away from constructing its first dwelling –but a scaled-down prototype has made an appearance at a recent exhibition. The companies behind Charlotte have ambitions for it to not only be put to work building homes a few years from now, but also Moon bases for lunar research in the future. They note that its versatile and compact bio-inspired design, coupled with its autonomous operation capabilities, make it ideal for use on the Moon.

While Charlotte's design currently appears to only support simplistic designs, its main utility will be in addressing the challenges of labor constraints and delays in building projects – both of which make it difficult to tackle housing shortages in many countries. The 3D-printed structures it creates are floodproof and fireproof, and the process is far quicker and cheaper than if it involved traditional building methods. If the ingredients for the Earthbuilt material are locally sourced, that can lower the carbon footprint too.

Naturally, such solutions won't be suitable for all markets, climates, and customer preferences. But for the millions of people bearing the brunt of housing deficits and the global housing mismatch, this sounds like a promising approach to partially tackling these issues.

Source: Crest Robotics