It goes without saying that it is very important for airliners' jet engines to be regularly inspected. Such inspections could soon be easier and more thorough than ever before, thanks to a robot that moves like an inchworm.

Currently, inaccessible parts of jet engines are imaged via borescopes, which are essentially long flexible tubes with a video camera on one end and an eyepiece or screen on the other.

The force of gravity often causes the camera-end of such devices to droop down unless braced against an engine part, however, plus it can be difficult to maneuver the camera deep into the engine. That's where Sensiworm is designed to come in.

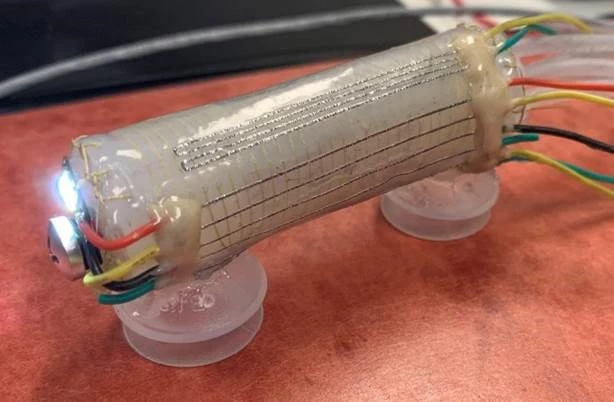

Its name an acronym for "Soft ElectroNics Skin-Innervated Robotic Worm," the bio-inspired soft-robotic device is being developed by a team of GE Aerospace Research engineers working with colleagues from New York's Binghamton University and Ohio-based research and development organization, UES, Inc.

After being deployed into the turbine inlet or exhaust port of a plane's engine, the compact robot is able to make its way through that engine via an inchworm-like push-pull style of locomotion facilitated by vacuum cups on its underside. As the bot does so it transmits live video from a forward-facing spotlight-assisted camera, imaging any cracks, corrosion or other problems it may encounter.

Importantly, though, Sensiworm doesn't just provide video. Sensors on the existing prototype are capable of sniffing out gas leaks and measuring the thickness of thermal barrier coatings on engine parts, with other sensing capabilities currently in the works.

Down the road, it is hoped that the robot could even be used to perform remote-control repairs. The final version of the device should be completely self-contained and untethered, housing its own power supply, microprocessor and other electronics.

"With mini-robot companions like Sensiworm, service operators would have multiple additional sets of eyes and ears to perform on-wing inspections," said Deepak Trivedi, Principal Robotics Engineer at GE Aerospace Research. "With their soft, compliant design, they could inspect every inch of a jet engine transmitting live video and real-time data about the condition of parts that operators typically check."

The robot's functionality is demonstrated in the following video.

Source: General Electric