Included in Superman’s suite of superpowers is X-ray vision, which allows him to see through solid objects. Using Superman as their inspiration, researchers from the University of Texas at Dallas (UTD) and the Seoul National University (SNU) have brought the ability to see into packages and through walls closer to being a reality using an imager chip small enough to fit into a smartphone.

“This technology is like Superman’s X-ray vision,” said Kenneth O, professor of electrical engineering at UTD, director of the Texas Analog Center of Excellence (TxACE) and one of the study’s co-authors. “Of course, we use signals at 200 gigahertz to 400 gigahertz instead of X-rays, which can be harmful.”

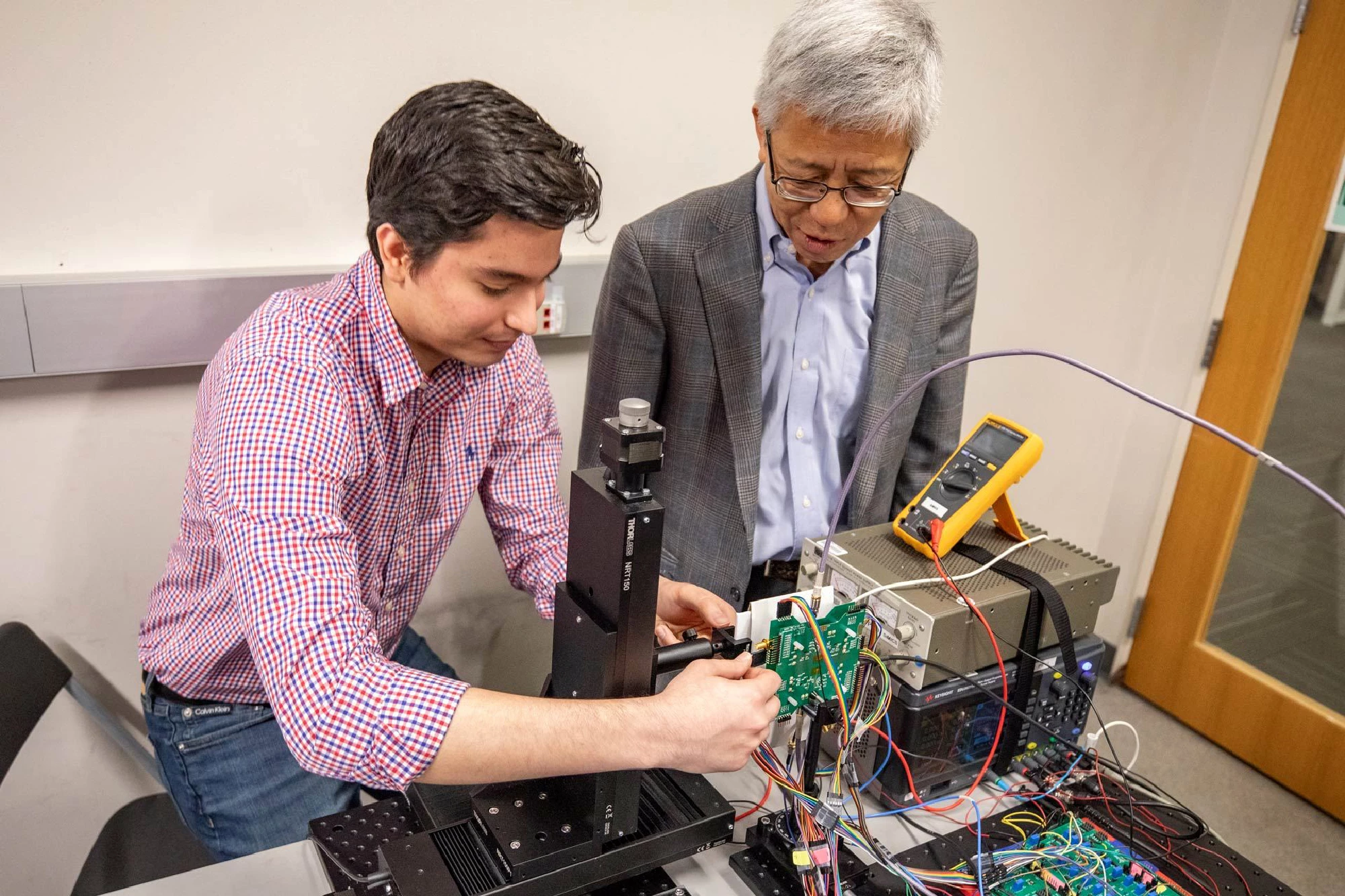

The imager microchip tech was first demonstrated in 2022, the culmination of more than 15 years of work by O and his team of students, researchers, and collaborators. The chip emits radiation in the terahertz (THz) range – that is, electromagnetic radiation in the frequency range between 0.1 THz (100 GHz) and 10 THz, with corresponding wavelengths from 3 mm down to 0.03 mm. These waves, invisible to the human eye and considered safe, are higher frequency than radio waves and microwaves but lower than those of infrared light.

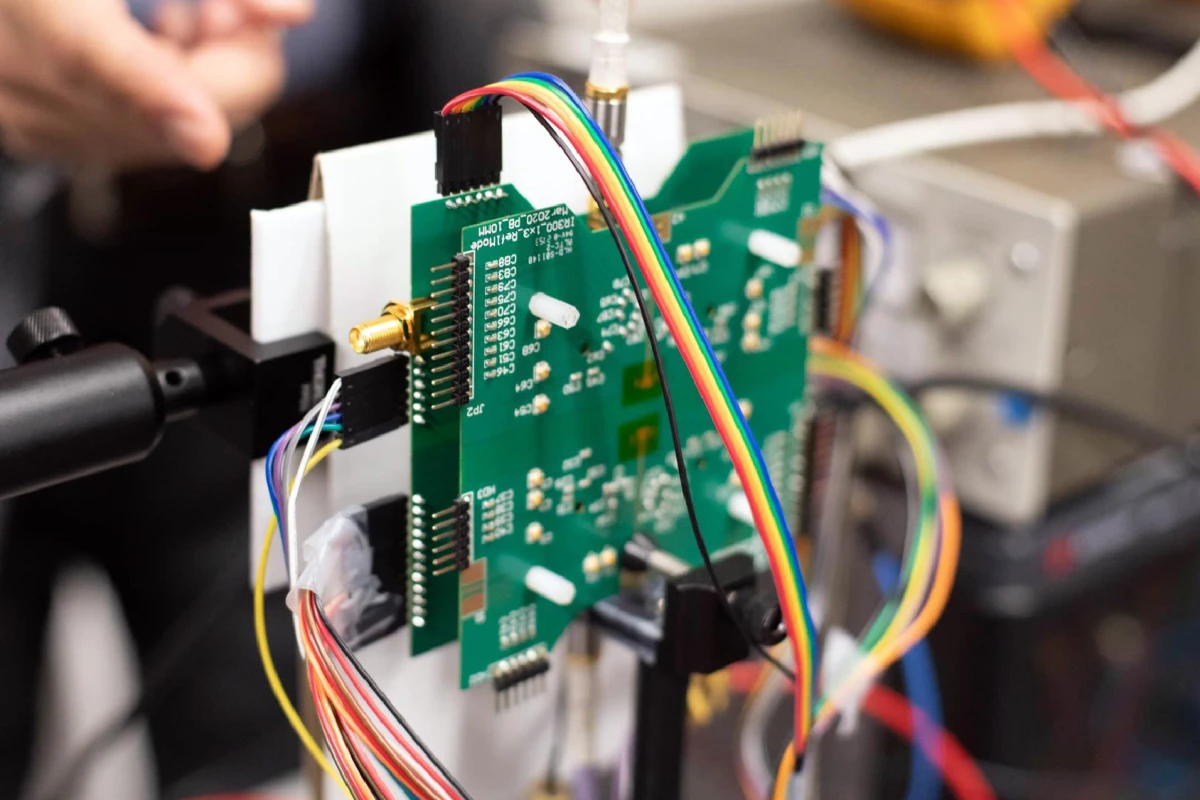

With the 2022 model, O demonstrated that 430 GHz beams produced by the microchip traveled through fog, dust, and other obstacles that optical light can’t penetrate. They bounced off objects and were reflected back to the microchip, where pixels picked up the signal to create an image. The imager didn’t rely on external lenses, which ordinarily would be used to improve image clarity and sharpness. Instead, it was made using the complementary metal-oxide semiconductor (CMOS) technology that’s used to manufacture modern consumer computer processors, memory chips, and other digital devices.

CMOS has emerged as an affordable way to generate and detect THz signals, especially at frequencies around 200 GHz and higher, which provides significantly better resolution. So, the researchers set about improving the image quality of their 2022 model and making the tech small enough to fit in a handheld device. The new imager chip used a 1 x 3 array of 296-GHz CMOS pixels and, again, was lens-less.

“We designed the chip without lenses or optics so that it could fit into a mobile device,” said Wooyeol Choi, assistant professor at SNU’s Department of Electrical and Computer Engineering and the paper’s corresponding author. “The pixels, which create images by detecting signals reflected from a target object, have the shape of a 0.5-mm square, about the size of a grain of sand.”

The technology was tested and could image objects (a USB dongle, a blade, an integrated circuit, and a plastic washer) covered with cardboard from about one centimeter (0.4 in) away. The researchers deliberately had the imager scan at a distance so close to the objects for safety and privacy reasons. Essentially, it was to allay fears that a thief could use the device, for example, to scan the contents of someone’s bag from a distance. The researchers plan to make the next iteration capable of capturing images up to five inches (12.7 cm) away.

“It took 15 years of research that improved pixel performance by 100 million times, combined with digital signal processing techniques, to make this imaging demonstration possible,” said Brian Ginsburg, director of radio frequency/millimeter wave and high-speed research at Texas Instruments (TI’s) Kilby Labs. “This disruptive technology shows the potential capability of true THz imaging.”

The researchers envision their smartphone-housed microchip imager being used for everything from finding studs and wooden beams behind walls to identifying cracks in pipes and the contents of envelopes and packages. They also consider it to have medical applications.

The Texas Instruments (TI) Foundational Technology Research Program on Millimeter Wave and High-Frequency Microsystems and the Samsung Global Research Outreach Program supported the research.

The study was published in IEEE Transactions on Terahertz Science and Technology.

Source: UTD