Researchers have used plasma technology to transform a species of blue-green microalgae into a bioactive coating with incredible wound-healing properties. They say the novel coating can be applied to dressings and medical devices to protect patients from infection, speed up healing and reduce inflammation.

Plasma is formed from gas so superheated that the electrons are ripped away from the atoms, resulting in a soup of positively charged ions and negatively charged electrons. An atmospheric pressure plasma jet (APPJ) provides a plasma discharge at ambient pressure using a noble gas/molecular gas mixture passed through a powerful electric arc discharge.

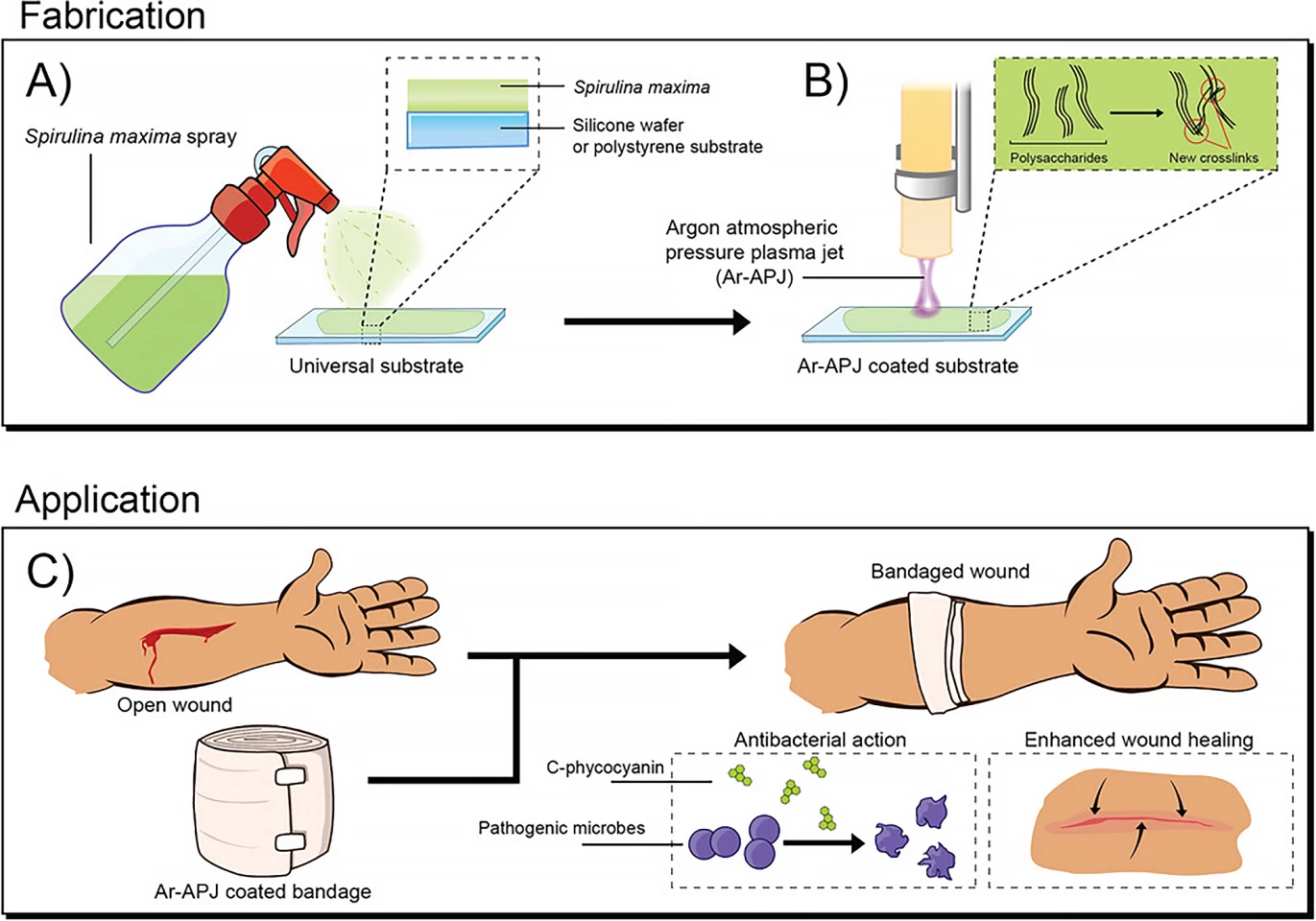

Researchers at Flinders University, South Australia, have used an argon APPJ to convert blue-green microalgae into an ultrathin bioactive coating that can be added to medical dressings to kill bacteria, reduce inflammation and promote wound healing.

“We are using the plasma coating technology to turn any type of biomass – in this case Spirulina maxima – into a sustainable high-end coating,” said Vi Khanh Truong, one of the study’s corresponding authors. “With our technology, we can transform biomass into coatings on wound dressing.”

Extract of S. maxima, a species of blue-green microalgae, is often used as a dietary supplement. The unicellular organism possesses a simple reproductive system that generates a biomass containing bioactive compounds with potent antioxidant and antibacterial properties that can assist with wound healing.

However, the thick cell walls of the microalgae pose a significant obstacle to extracting these valuable compounds. That’s where APPJ comes in. The researchers used the technology to selectively break down the microalgae’s thick walls, which resulted in a significant transformation. S. maxima lost its native structure, completely disintegrated, and subsequently reformed into ultrathin films.

The antibacterial activity of the argon APPJ-treated S. maxima was assessed and found to be highly effective against Pseudomonas aeruginosa and Staphylococcus aureus, with 93% and 73% cell death, respectively, and inhibited biofilm formation. Bacteria inside biofilm are much more resistant to antibiotics.

In addition to being biocompatible, the S. maxima coating exhibited anti-inflammatory properties. And a wound created by the researchers using wound scratch assay was completely closed in two days when the coating was used.

The researchers say this novel technique holds promise as a wound treatment, including the treatment of chronic wounds, particularly given the rise in antibiotic resistance.

“This new, plasma-facilitated downstream processing can improve extraction and purification of useful compounds from biomass without the need for harmful solvents and a lot of energy input,” said Krasimir Vasilev, the other corresponding author of the study. “We are now exploiting avenues for commercialization of this unique technology. Currently, there is no commercial wound dressings that simultaneously fight and protect from infection, favorably modulate inflammation and stimulate healing.”

The study was published in the journal Small.

Source: Flinders University via Scimex