Researchers have developed a product that reduces hair’s moisture-absorbing tendencies, maintaining frizz-free curls for at least six hours in high-humidity environments and even allowing them to bounce back thanks to its shape-memory properties.

Hairstyles are an expression of individuality and creativity and boost self-confidence. Anyone with curly hair knows that humidity is the natural enemy of curls because it leads to frizzing. In muggy weather, moisture actively penetrates the hair cuticle, causing swelling and leading to a fluffy, frizzy mane. Flat ironing can be used to mitigate this phenomenon, but it’s time-consuming and restricts people to sporting a straight ’do when they might want to show off their curls.

Now, researchers from the National Institute for Materials Science (NIMS) have partnered with Nihon L’Oréal K.K. to tackle this problem head-on (pun intended) to create an innovative humidity-responsive hair product with shape memory features.

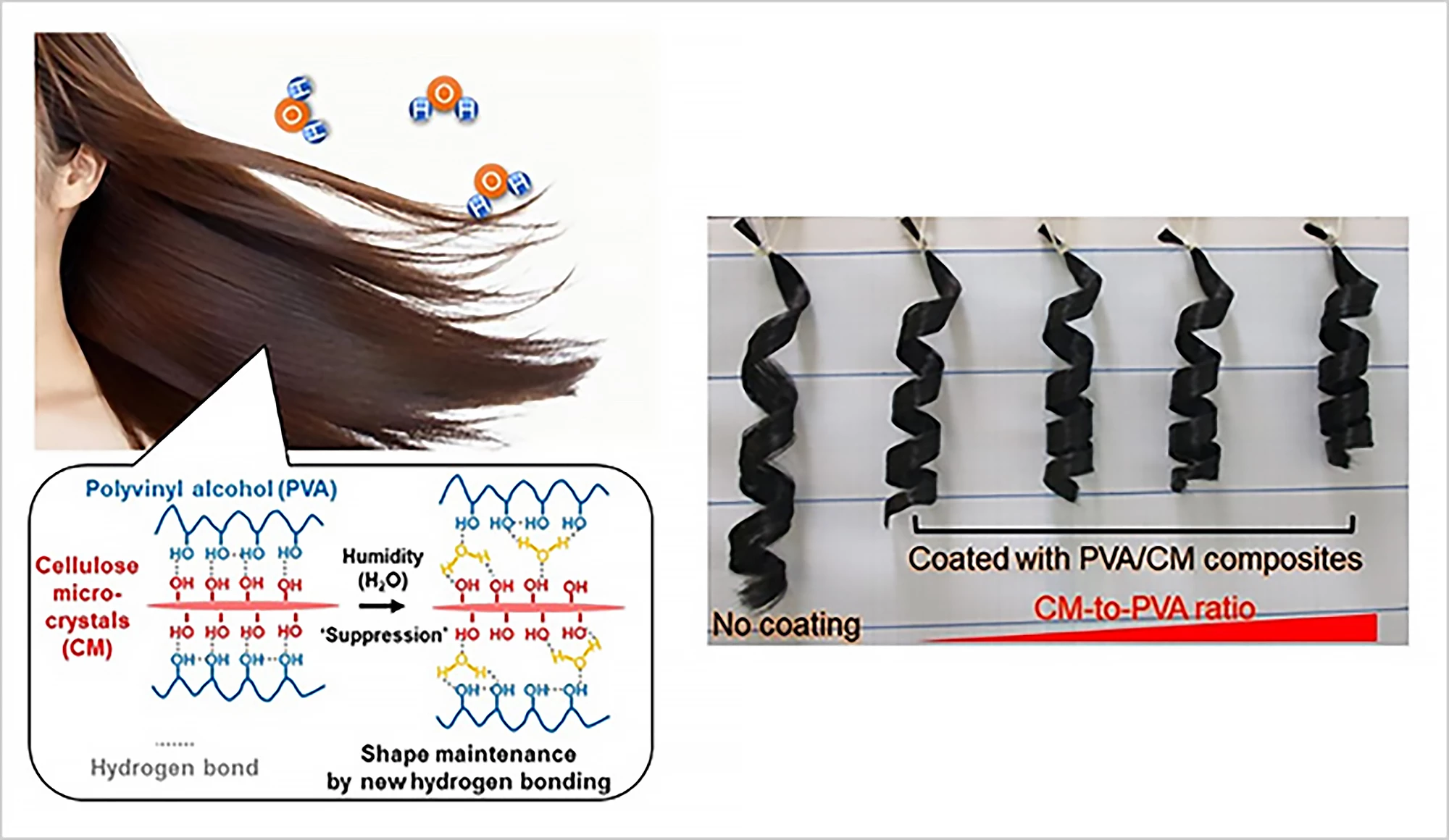

The researchers started with polyvinyl alcohol (PVA), a well-known, human-skin-compatible, environmentally friendly polymer that’s water-soluble and easy to form. Then they added cellulose microcrystals (CM) to it. Cellulose is the most abundant, biodegradable, renewable and inexpensive polymer found in nature. The presence of hydroxyl groups in cellulose facilitates the formation of hydrogen bonds with PVA, providing improved mechanical and barrier properties, high moisture resistance and thermal stability, and UV light absorption.

Despite existing knowledge about PVA’s shape memory performance, there have been few attempts to improve or enhance it. So, the researchers set about investigating PVA/cellulose composites that could be used in hair curl maintenance products to improve their shape memory performance in the face of high humidity.

They evaluated composite films created by mixing PVA and CM in different weight ratios, focusing particularly on moisture absorption and mechanical properties. The researchers found that when PVA-only films are exposed to high humidity conditions, moisture absorption persists for a long period until equilibrium is reached, resulting in a decrease in mechanical strength. By contrast, adding CM to the PVA markedly inhibited the uptake of water molecules into the film and allowed it to maintain low moisture absorption states for long periods. PVA/CM composites could also maintain high mechanical properties during moisture absorption.

Evaluating the humidity-responsive shape memory of the composite films, those with CM content from 20% to 25% exhibited superior shape recovery and maintenance, whereas those with a CM content of 33% had reduced performance.

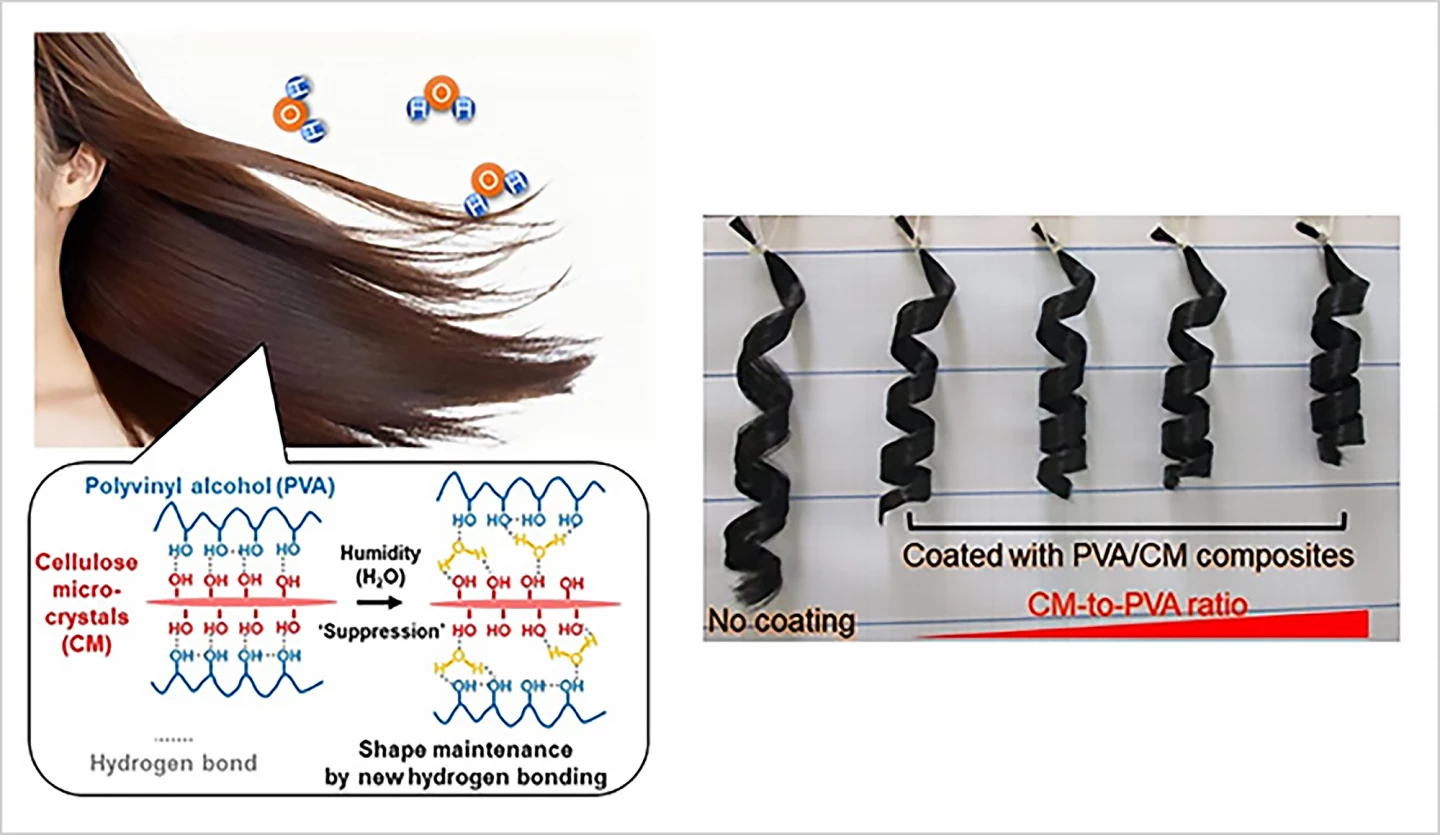

To investigate whether the PVA/CM composites could be used to maintain hairstyles under high humidity conditions, aqueous solutions with PVA and different PVA/CM ratios were used to coat natural hair bundles, and curls were created using a hair iron at 356 °F (180 °C). When the curled hair bundles were stretched overnight by applying a 13-g force load, their lengths were not significantly different. However, compared to hair treated with water only, coating with PVA and PVA/CM notably suppressed hair spreading and frizzing.

When the temporarily stretched hair was placed in a chamber with 80% relative humidity for six hours, its lengths were shortened by returning to the original curly hair shape. After 360 minutes of high-humidity exposure, the water-treated hair bundle showed the poorest curl retention, while the bundles coated with PVA and PVA/CM at a ratio of 4/1 maintained their curl shape better than the other compositions.

The PVA/CM composite films showed a significantly higher shape recovery rate and subsequent shape maintenance than pure PVA, and PVA did not show any notable shape recovery performance after exposure to high humidity for an extended period. In contrast, the composite-treated hair bundle recovered around 10% of its shape and maintained it.

To the best of the researchers’ knowledge, this is the first study to evaluate the application of PVA/CM composites as humidity-responsive shape memory polymer hair coatings that assist with hairstyle maintenance by preventing moisture absorption.

Overall, the results suggest that cellulose is an effective filler to reinforce PVA against humidity and that the ratio of PVA to CM in the composite is critical to achieve both moisture absorption resistance and shape memory properties. The findings demonstrate the PVA/CM composite’s potential use as a humidity-resistance hairstyling agent.

The study was published in the journal Advanced Materials Interfaces.

Source: NIMS