Ordinarily, the microcircuit patterns used in microchips are printed onto flat silicon wafers, potentially limiting the chips' applications. A new technique, however, lets such patterns be more easily applied to curved surfaces – and it uses "candy" to do the job.

First of all, there already are a couple of methods of applying micropatterns to irregular surfaces, but they both have their limitations.

In one technique, a pattern is initially printed onto a flat substrate, then lifted off of it using a piece of flexible adhesive tape. That tape is subsequently pressed onto the curved target surface then peeled off again, transferring the lifted pattern to that surface in the process. Unfortunately, though, the tape can't always reach into tight corners, plus it may leave adhesive residue on the target surface after it's been removed.

Another approach involves floating the micropattern on the surface of some water, then gently lowering the target item face-down into that water. As the item goes through the water's surface, the pattern clings to its surface. With this technique, however, precise placement of the pattern on the target surface can be difficult.

The new candy-based process addresses such shortcomings. It's known as REFLEX (REflow-driven FLExible Xfer), and it was developed at the US National Institute of Standards and Technology (NIST) by a team led by Dr. Gary Zabow.

As with the tape technique, the first step entails printing the micropattern onto a flat substrate. A mixture of caramelized sugar, corn syrup and water is then poured onto the pattern, and left in place until the water has evaporated. When the now-hardened sugar/syrup "candy" is subsequently pulled off, the pattern comes with it.

Next, the candy is placed on the curved target surface, then heated. This causes it to melt and become viscous, allowing the lifted micropattern to flow precisely into all the surface's nooks and crannies. In a final step, water is used to wash away the molten sugar and syrup, leaving the pattern securely in place.

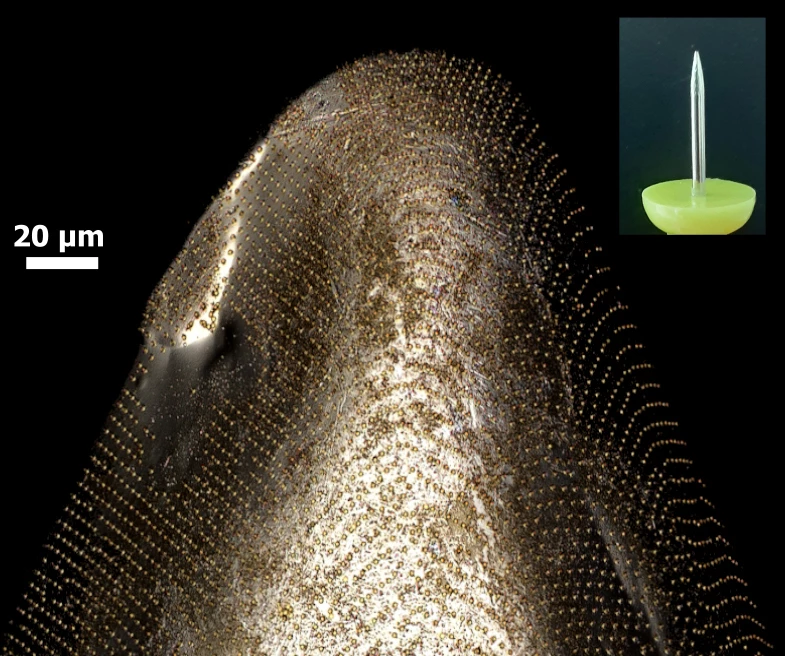

In tests performed so far, the REFLEX technique has been used to transfer gold lettering (spelling out the acronym "NIST") onto a human hair, and to apply a grid of 1-micron-wide magnetic discs onto both the sharp end of a pushpin and a floss fiber of a milkweed seed. It is hoped that once developed further, the technology could allow for new capabilities in biomedical or microrobotic devices.

"The semiconductor industry has spent billions of dollars perfecting the printing techniques to create chips we rely on," said Zabow. "Wouldn’t it be nice if we could leverage some of those technologies, expanding the reach of those prints with something as simple and inexpensive as a piece of candy?".

A paper on the research was recently published in the journal Science.

Source: NIST