Michigan-based Sintercore is billing its Auxetik (pronounced Aug-ZETIK) as the first commercial 3D printed firearm muzzle brake. Made of Inconel alloy using a laser additive manufacturing process, the Auxetik is designed to tame the recoil and muzzle rise of AR-15 pistols chambered for .223 caliber (5.56x45mm) NATO rounds.

The AR-15 is the semi-automatic civilian version of the military M-16, which is used by over 80 countries. While the AR-15 is used for target shooting and hunting, it also occupies an unusual position in the gun world by account of its modular design that allows for extensive customization.

When the stock of an AR-15 is removed and there is only one grip, it is considered under US ATF (Alcohol, Tobacco, and Firearms) regulations to be a pistol. This allows it to be used with a short barrel, typically in the 6 to 12 inch range, whereas as a rifle the barrel must be longer than 16 inches to avoid special licensing requirements.

The AR-15 pistol modification does not result in the most practical firearm. Such a pistol has stronger recoil and muzzle flip than do the rifle versions, as you might expect from a lighter gun, the backward shift in the center of mass of the gun and the loss of stabilization from the stock. Adding a muzzle brake to direct the propellant gases emerging from the barrel upwards and backwards help to minimize these effects, and make the pistol more controllable.

Sintercore has developed a new muzzle brake design for exactly this purpose – taming the AR-15 pistol. Its muzzle brake includes design elements that would be difficult and expensive to create using conventional machining methods, including being fabricated from an Inconel alloy, so it has chosen to use 3D printing via the Direct Metal Laser Sintering (DMLS) process.

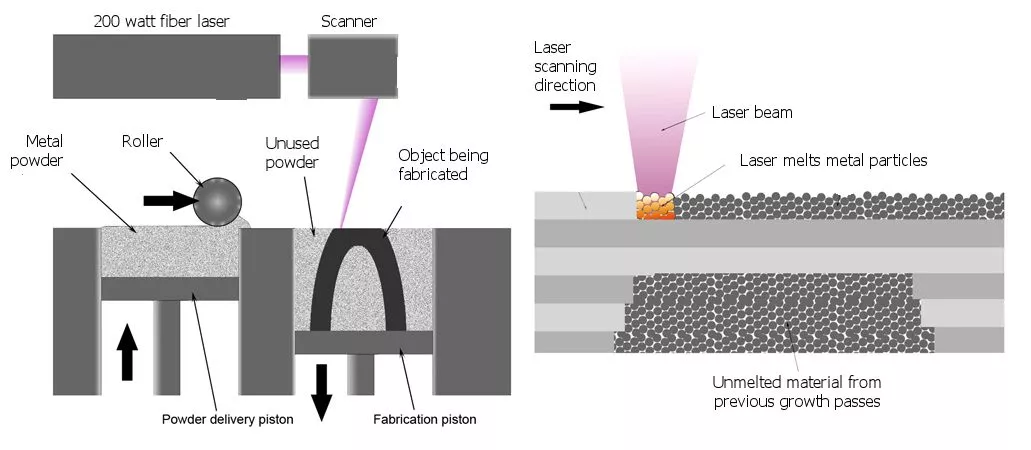

DMLS is a bit of a misnomer, as the process does not involve sintering. Sintering is a process in which a powder is consolidated by using heat and pressure to activate atomic diffusion near the particle surfaces to join the particles together into a mass. This mass, however, typically still contains voids, and the grain boundaries between particles tend to be relatively weak.

In contrast, in the DMLS process, an object being "grown" is covered with a very thin layer of metal power, which is then scanned by a laser so it melts, along with a thin layer of the underlying growth surface, thereby forming a full density solid object.

DMLS is capable of great accuracy, with thickness of the growth layers being as small as 20 microns (0.0008 inch), and tolerances perpendicular to the growth direction of about 100 microns (0.004 inch). It is a slow process at present, adding about 2 cubic millimeters per second (about 7 cc/hr) when growing an object of Inconel alloy, but this may improve with additional developmental work.

Using this process,the Inconel has about 70 percent of the strength of properly heat-treated Inconel. The lower strength is caused by the rapid solidification of the alloy after the laser passes over. Once the DMLS Inconel parts are subjected to a standard heat-treatment, they display strength and ductility nearly identical to a more conventionally machined component.

The finished design is shown above, with a target's eye view of the Sintercore Auxetic muzzle break in the center. The gases are preferentially directed upward and to the sides, but the internal structures that direct the gas backward to reduce recoil cannot be seen in the image. The final result functions quite well, as can be seen in the video below.

And the cost? The Auxetic is available at a suggested retail price of US$300. A conventional muzzle brake made of softer materials costs perhaps $80, while a competing upper-end muzzle brake made of Inconel is available for about $400. The word on the web is that Inconel is overkill for the functional purpose, but it looks and performs well. The real significance, though, is that Sintercore has taken a step toward a new method of designing and fabricating firearms.

Source: Sintercore