What does it take for a quadcopter to carry a 10-kg (22-lb) payload and fly for three hours straight? It takes petrol power – and a clever variable pitch rotor system that makes this gas-powered drone just as stable, quick and responsive as its electric brethren. Scaled up, it could carry 200 kg (441 lb), which is more than enough lifting power for a manned multirotor.

Multirotors are terrific, practical tools for a lot of different applications, but until that next great leap in battery technology we've been waiting years for, they still can't lift much for any length of time.

Gasoline still has a higher energy density than our best commercially available batteries, by a factor of almost 100, so maybe a petrol-powered quad could deliver a huge endurance advantage. But internal combustion engines don't have the instant torque and responsiveness of an electric motor and they can't adjust the speed of a single propeller hundreds of times per second like you need to do to keep a quadcopter stable.

In fact we've only really seen one gas-powered quad that looked remotely safe and stable – the German Yeair drone. Each of the Yeair's props is driven by a tiny two-stroke engine, which provides bulk power and endurance, but each prop shaft also has an electric motor operating on it, providing the instant torque you need for quick adjustments. The Yeair can fly for an hour, which is about twice as good as what most regular battery quads can handle.

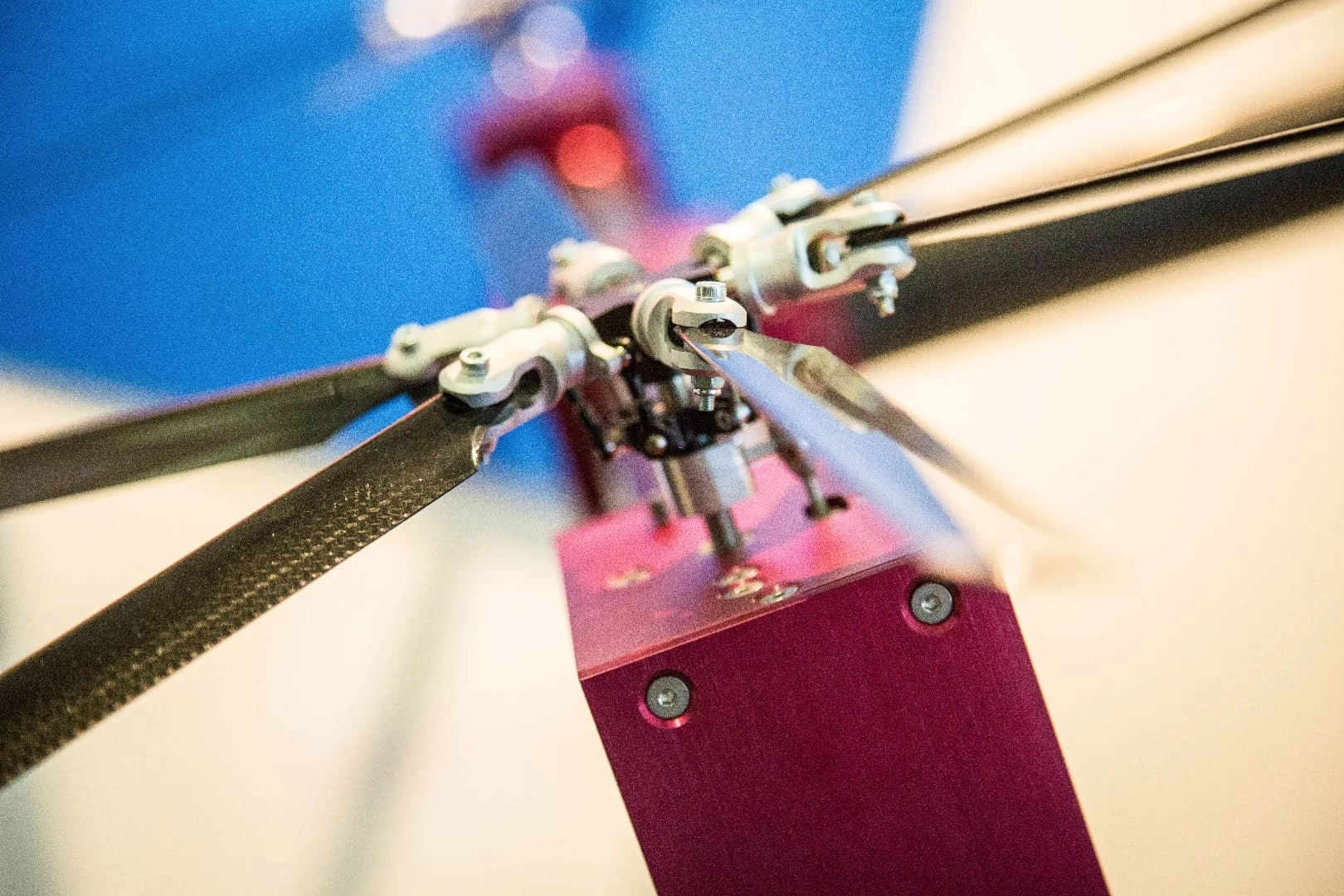

But at this year's Avalon Air Show in Australia, another solution has popped up. Canberra-based company SOAPdrones has successfully built a petrol-powered quadcopter that uses a single two-stroke engine spinning four variable pitch props. Because each prop's pitch is controlled by a quick servo motor, it can generate or reduce lift as quickly – or perhaps even faster – than an electric motor.

That's how the Belias drone can give you a whopping three hours of petrol-powered endurance, heavy lift capability up to 10 kg (22 lb) payloads, and a flight platform that SOAPdrones technical director Paul Riess describes as "very stable and very responsive."

"This prototype has not yet flown," Riess tells us, "but we've had smaller ones in flight. It's a 120cc two-cylinder two-stroke engine. A hobby engine meant for model aeroplanes. We plan to upgrade that at a later date with a CASA certified engine."

SOAPdrones (which stands for Snakes On A Plane drones, as the business was originally intending to run an anti-venom delivery service to remote areas in Australia) had to develop its own flight control software to manage the variable pitch lift system.

"You can't just put a standard flight controller in there and have it work, but it's all possible," says Riess, "The throttle, we want the motor to remain at a constant RPM. The pitch of the props will control the speed and direction and everything else. We have to monitor the speed of the petrol engine so it remains consistent. When it gets bogged down by the changing of the pitch of the rotors, we have to keep it consistent."

Going big: 200 kg payloads and potential "flying car" applications

The Belias might look like a pretty sizable prototype, at around 1 x 1 m (3.3 x 3.3 ft), but this kind of heavy-lift, high-endurance flight platform can very easily scale. Riess tells us "The eventual plan is to lift 200 kilos (441 lb), to fly for three hours, from Canberra to Sydney. We're expecting a maximum speed of around 100 km/h (62 mph).

"We try not to say "flying car" – it kind of sets the crackpot alarm off. But secretly, we think yeah, this could be a flying car. Having that kind of payload allows us to add on all sorts of interesting things in terms of bodywork, aerodynamics. A lot of smaller drones, they just can't carry the weight to look at aerodynamics and safety equipment, like putting a parachute on it at some stage, that's something you can do with that kind of payload."

Any talk of manned multirotor action is clearly a long way down the track. And with a single motor and a presumably fairly complex drive system getting power to the props, there would be less redundancy and greater mechanical complexity with more points of potential failure than any of the many electric designs we've covered lately. Still, thanks to its petrol powerplant, the SOAPdrones variable pitch platform would be the first we've seen that could lift a person for any length of time right now, using existing technology.

We look forward to seeing how the platform evolves, and wish the SOAPdrones team every success.

Source: SOAPdrones