A team of scientists at the Georgia Institute of Technology have come up with a concept that would see bacteria shipped to Mars produce rocket fuel and liquid oxygen from atmospheric CO2 to power a spacecraft on its return journey to Earth.

Around the end of the decade, a rocket will lift off from Mars containing about half a kilogram (1 lb) of geological samples collected by NASA's robotic Perseverance rover. Though the rocket will only be sending the samples and their container into Mars orbit for retrieval by another spacecraft for the trip home, it will weigh about 880 lb (400 kg), with most of that taken up by the solid rocket fuel needed for the ascent.

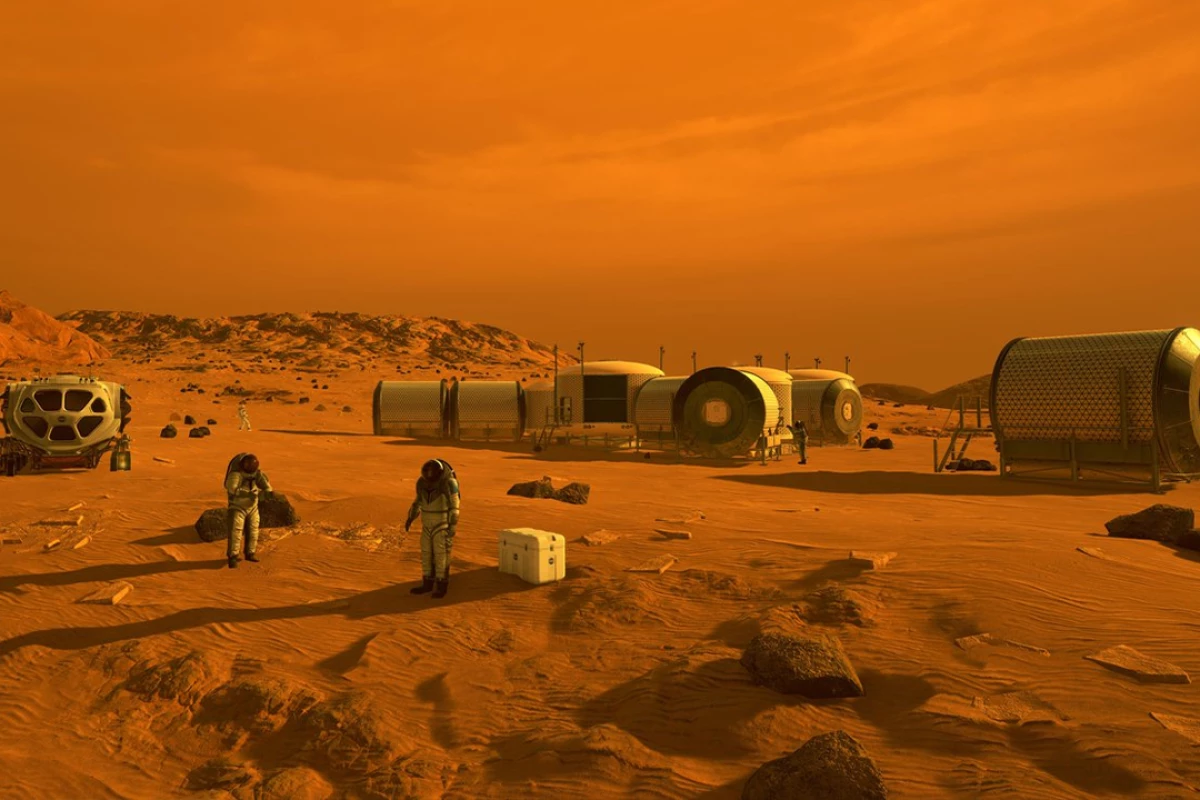

With that as the benchmark, now imagine how much fuel future, more ambitious missions to Mars will need – especially if these missions are carrying astronauts. According to Georgia Tech, a crewed Mars Ascent Vehicle (MAV) would require 30 tonnes of methane and liquid oxygen to put 500 kg (1,100 lb) of payload into orbit. Though it's possible to produce liquid oxygen on Mars, the methane would have to come from Earth, meaning an initial payload lifting off from Earth weighing 500 tonnes and costing US$8 billion to transport the additional fuel.

To cut down on costs and free up payload space for something more useful than fuel for the return trip, the Georgia Tech team led by Nick Kruyer wants to use cyanobacteria and genetically engineered E. coli to produce an alternative fuel known as 2,3-butanediol (CH3CHOH)2, which is used on Earth to make synthetic rubber and other polymers. In addition to providing enough oxygen for the rocket, the proposed technique would also produce 44 tonnes of excess oxygen that could be used for other purposes.

The basic idea is that a series of pathfinder missions would be sent ahead of the main mission. These would consist of samples of the microorganisms plus the plastic materials needed to set up photobioreactors with an area of four football fields.

In these reactors, sunlight and carbon dioxide from the atmosphere would be provided to the cyanobacteria, which would then be treated with enzymes to produce sugars. These sugars would be extracted and fed to the E. coli to produce the 2,3-butanediol and oxygen, which would be separated out by further steps in the process.

According to the team's calculations, the process would be 32 percent more efficient than a proposed chemical plant producing oxygen on Mars via chemical catalysis using methane shipped from Earth – though it would be three times as heavy. The next step will be to come up with ways to make the equipment smaller and lighter and the biological side of the process faster and more efficient.

"We also need to perform experiments to demonstrate that cyanobacteria can be grown in Martian conditions," says Matthew Realff. "We need to consider the difference in the solar spectrum on Mars both due to the distance from the Sun and lack of atmospheric filtering of the sunlight. High ultraviolet levels could damage the cyanobacteria."

The process was published in Nature Communications.

Source: Georgia Tech