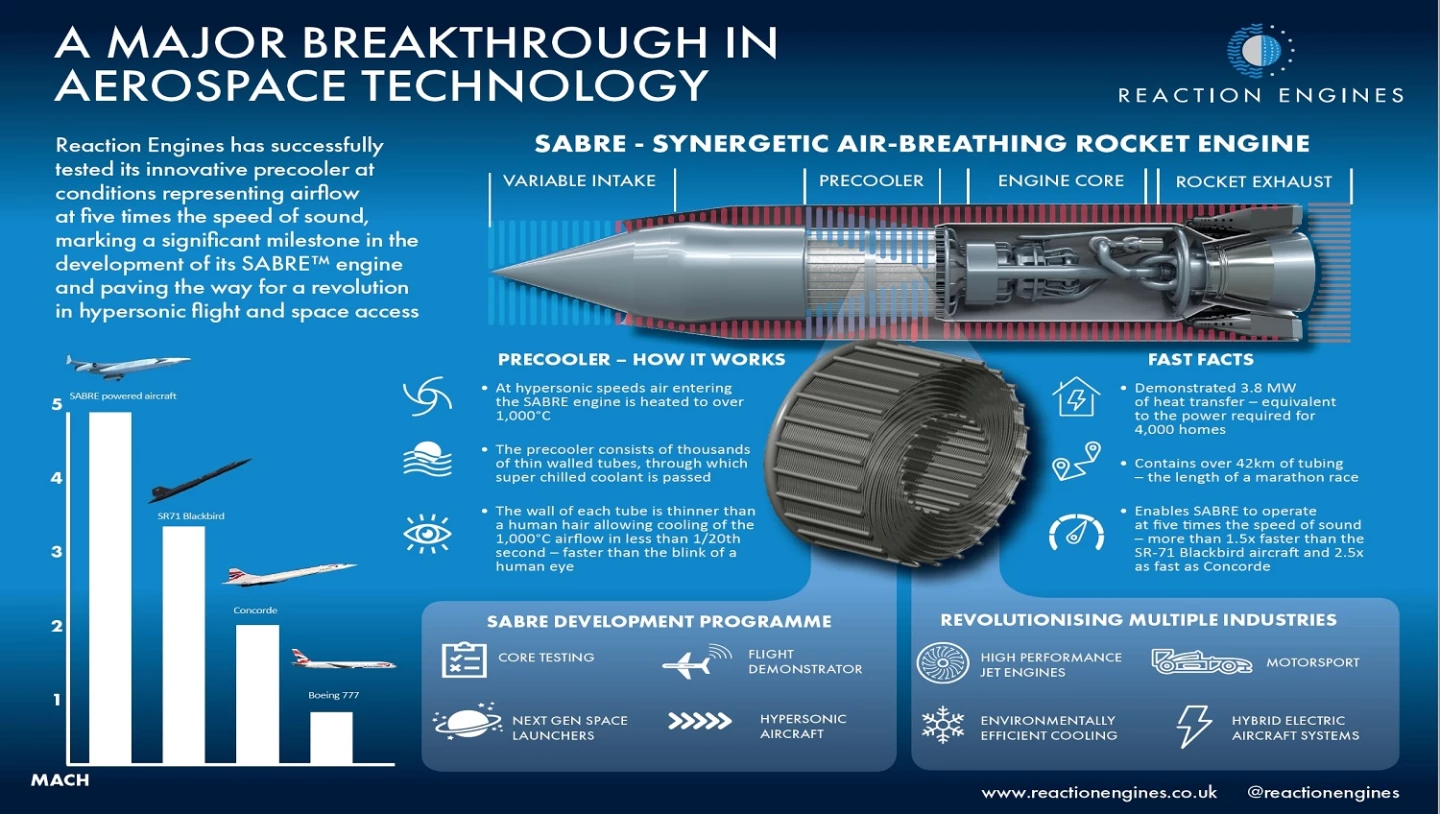

Reaction Engines' Synergetic Air-Breathing Rocket Engine (SABRE) has passed a major milestone, as one of its key components handled conditions equivalent to an airspeed of Mach 5 (3,704 mph, 5,961 km/h). In ground tests at the Colorado Air and Space Port, the hybrid engine's precooler handled a hotter, faster airflow than any previous jet-powered aircraft could tolerate.

The latest tests of the SABRE precooler represent a major step toward making the engine operational because Mach 5 is the switchover point when the SABRE changes from an air-breathing jet engine to a pure rocket engine burning hydrogen and liquid oxygen, making speeds of up to Mach 25 (17,521 mph, 29,808 km/h) possible.

Key to this is the precooler, which can handle air coming in with a force 25 times that of a category 5 hurricane and dampen temperatures that would melt any material that the engine core might be made of. Using recirculated cryogenic hydrogen fuel to cool incoming air, the precooler can quench the hypersonic airflow down from a temperature of 1,000° C (1,832° F) to -150° C (-302° F) in 1/20th of a second.

The recent tests follow a previous series of Hot Heat eXchanger (HTX) tests in April when the precooler handled airflows equivalent to Mach 3.3 (2,447 mph, 3,939 km/h) and temperatures of 420° C (788° F). When fully developed, the precooler will not only help power the SABRE engine for hypersonic flights and orbital launches, but also can be used in a range of automotive, aerospace, energy and industrial applications.

"This is a major moment in the development of a breakthrough aerospace technology which has seen Reaction Engines’ precooler tested at Mach 5 airflow temperature conditions, smashing through previous achievements at Mach 3.3 temperatures and paving the way for hypersonic flight," says Mark Thomas, Chief Executive, Reaction Engine. "In addition to its use in our SABRE class of air-breathing rocket engines, there are numerous exciting commercial applications for our precooler technology, which delivers world-leading heat transfer capabilities at low weight and compact size, and we are seeing significant interest from a range of potential customers and technology partners."

Source: BAE Systems