NASA is getting into the textile business thanks to a team led by systems engineer Raul Polit Casillas at the Jet Propulsion Laboratory in Pasadena, California. The team has unveiled prototype swatches of a new metallic "space fabric" created using 3D printing that incorporates advanced functions that would be beneficial for use in space.

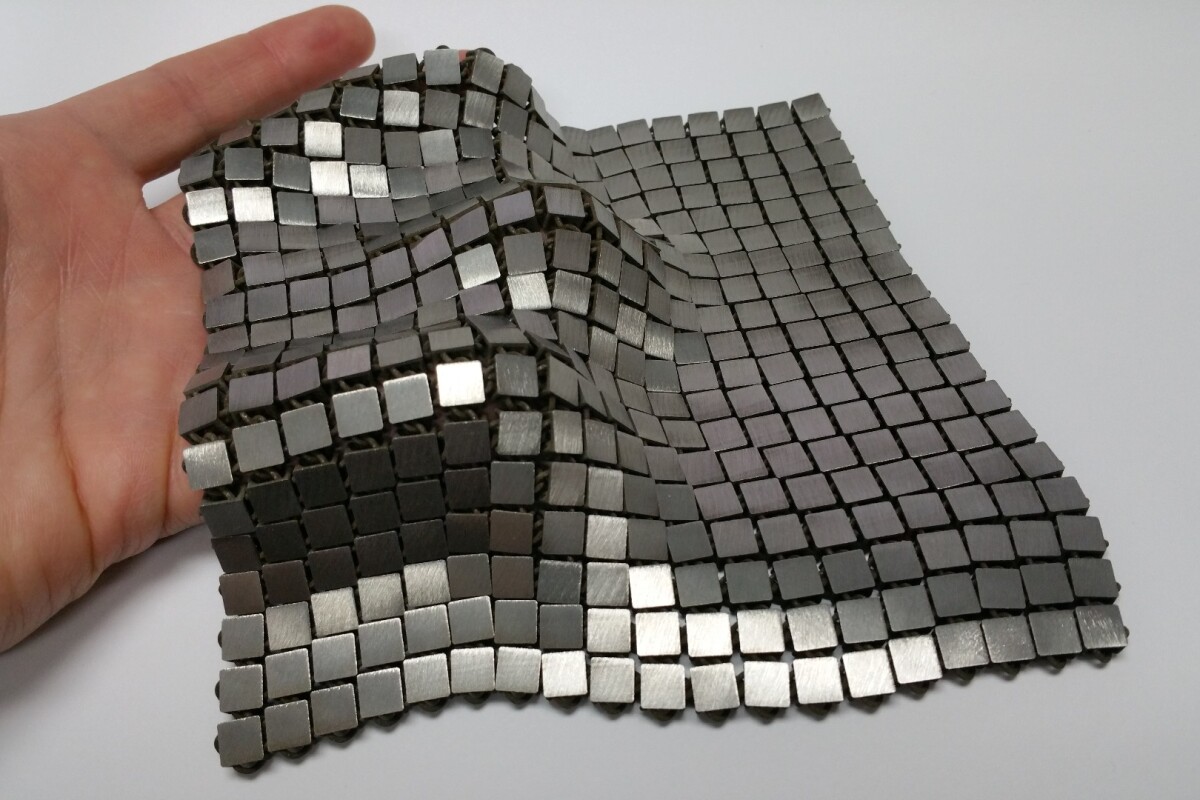

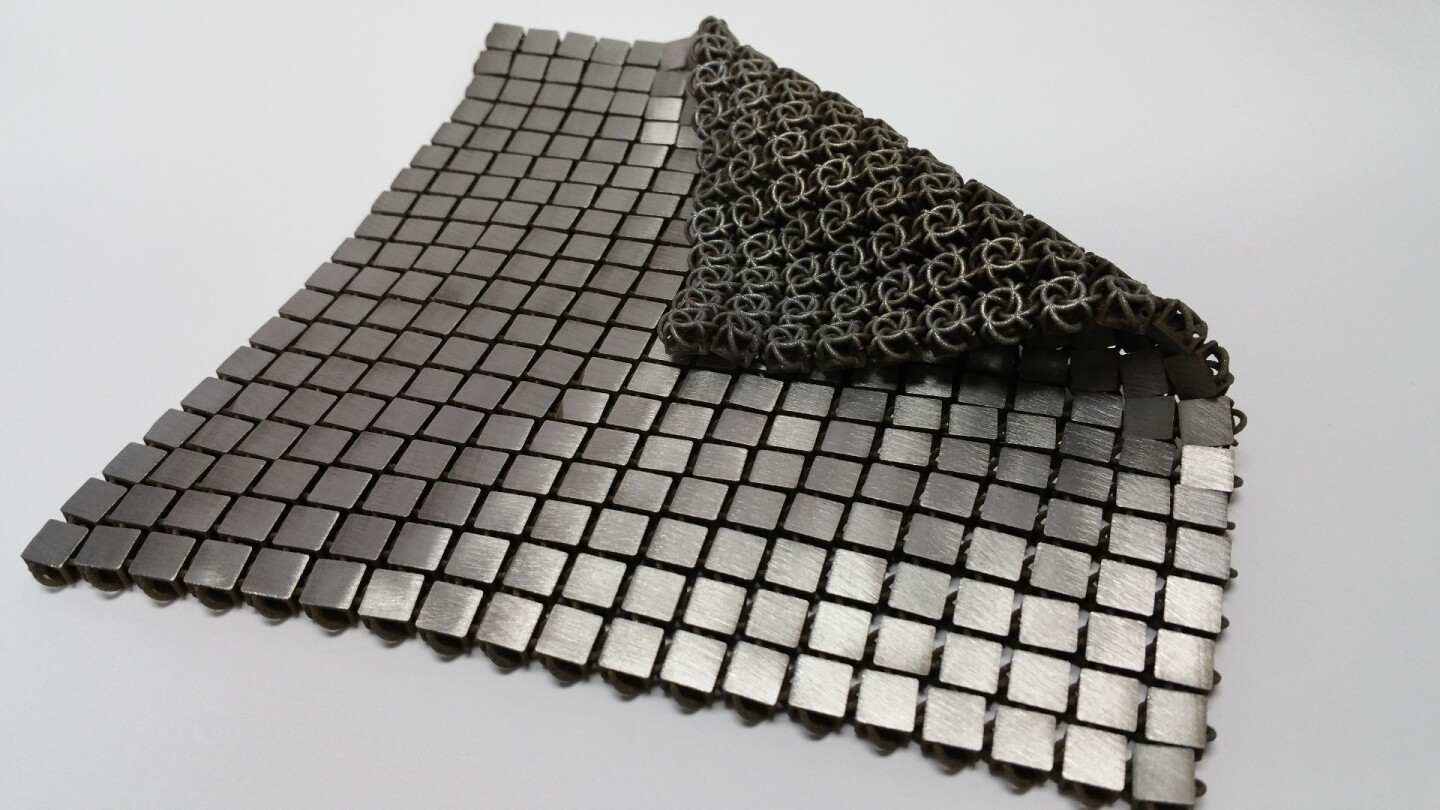

To the naked eye, the space fabric looks like a cross between chain mail and metallic tiles, like something you might see in one of the more "with it" haute couture dresses of the Swinging Sixties. But this odd design is more than a fashion statement, with one side of the fabric that can reflect light and heat, while the opposite side absorbs it. NASA says that by folding the material in different ways, it can conform to various shapes and produce the desired levels of reflectivity, passive heat management, and tensile strength.

The fabric was produced using additive manufacturing, where an object isn't milled or assembled, but built up layer by layer in one piece using streams of molten polymers or sintering metallic powders using precisely controlled lasers or electron beams. This allows for items to be made of very few parts needing final assembly, speeds up prototyping, greatly reduces costs, and allows for designs that would be impossible to produce using conventional methods.

In the case of the space fabric, Polit Casillas prefers to call this "4D printing" because it allows engineers to print both a desired geometry and function directly into a material. This control also allows a material to incorporate multiple functions as well as produced organic, non-linear shapes at relatively low cost.

The space agency sees the fabric as potentially having a variety of applications, including large antennas that can be folded and change shape quickly, and insulation for spacecraft visiting cold, icy moons and planets. It could also be used in flexible, insulated foot pads that would give landers and rovers a firm footing without melting the ice beneath them, micrometeorite shields for spacecraft, astronaut spacesuits, and for collecting samples on other planets.

The team hopes that such fabrics will not only be used in space, but manufactured there as well as a means of conserving and recycling scarce resources aboard spacecraft. In addition, it could also change the way spacecraft are engineered, allowing them to be created "whole cloth" instead of many discrete components that increase the potential points of failure.

"I can program new functions into the material I'm printing," says Polit Casillas. "That also reduces the amount of time spent on integration and testing. You can print, test and destroy material as many times as you want."

Source: NASA