A team of Dutch scientists has taken on the grueling task of designing the perfect piece of chocolate, using novel 3D printing techniques to create designs that shatter in the most pleasurable way when bitten. Clearly, extensive testing is required.

Some of us heathens are content merely to shovel handfuls of supermarket-grade choccies into our mouths and leer brown-toothedly at our offspring. For other folk, chocolate is a pleasure to be taken very seriously. There are chocolate tasting courses in which people can explore the subtleties of flavor, texture, mouthfeel and melt, thus ruining M&Ms for themselves forever.

An expert chocolatier has to act somewhat like a blacksmith, heating and cooling their emulsion precisely to select for the perfect crystal lattice structure formation – cocoa butter, as physicist and choc shop owner Richard Tango-Lowy tells Chemistry World, "is a six-phase polymorphic crystal." Phase V is the most desirable – it crackles and melts rather than crumbling, and gives high-end chocolates their delectably glossy sheen. But it can take weeks for a piece of properly-tempered chocolate to crystallize completely, and what's more, phase V crystals are unstable, and tend to degrade into dull phase IV crystals over time.

This is merely to illustrate that a ton of thought and expertise, and no small amount of science, goes into every stage of high-end sweet manufacture. So it shouldn't be a surprise to learn that it's attracted the attention of metamaterials and 3D printing specialists at the University of Amsterdam, who have just published a paper in the journal Soft Matter on their exploration of the perfect structures for optimal chocolatey mouthfeel.

They set out with a reasonable idea in mind: that most people enjoy the experience of chocolate crackling as they bite down on it, and that the more cracking, the better. They began trying to design shapes that would maximize these "fracture events," finding that spiral shapes provided ample opportunity to engineer and tune crackle points, depending on which direction the bite comes from.

They put a series of designs before a "very willing" test panel, and took sound recordings of these people biting each design. Sure enough, they found that a greater number of spiral windings produced an audibly greater number of crackle events, and they confirmed that the test participants were able to distinguish between the more and less crackly designs, and yes, "the overall sensory rating, as well as the perceived number of cracks, exhibit a positive correlation with the number of cracks measured from the force-displacement curve."

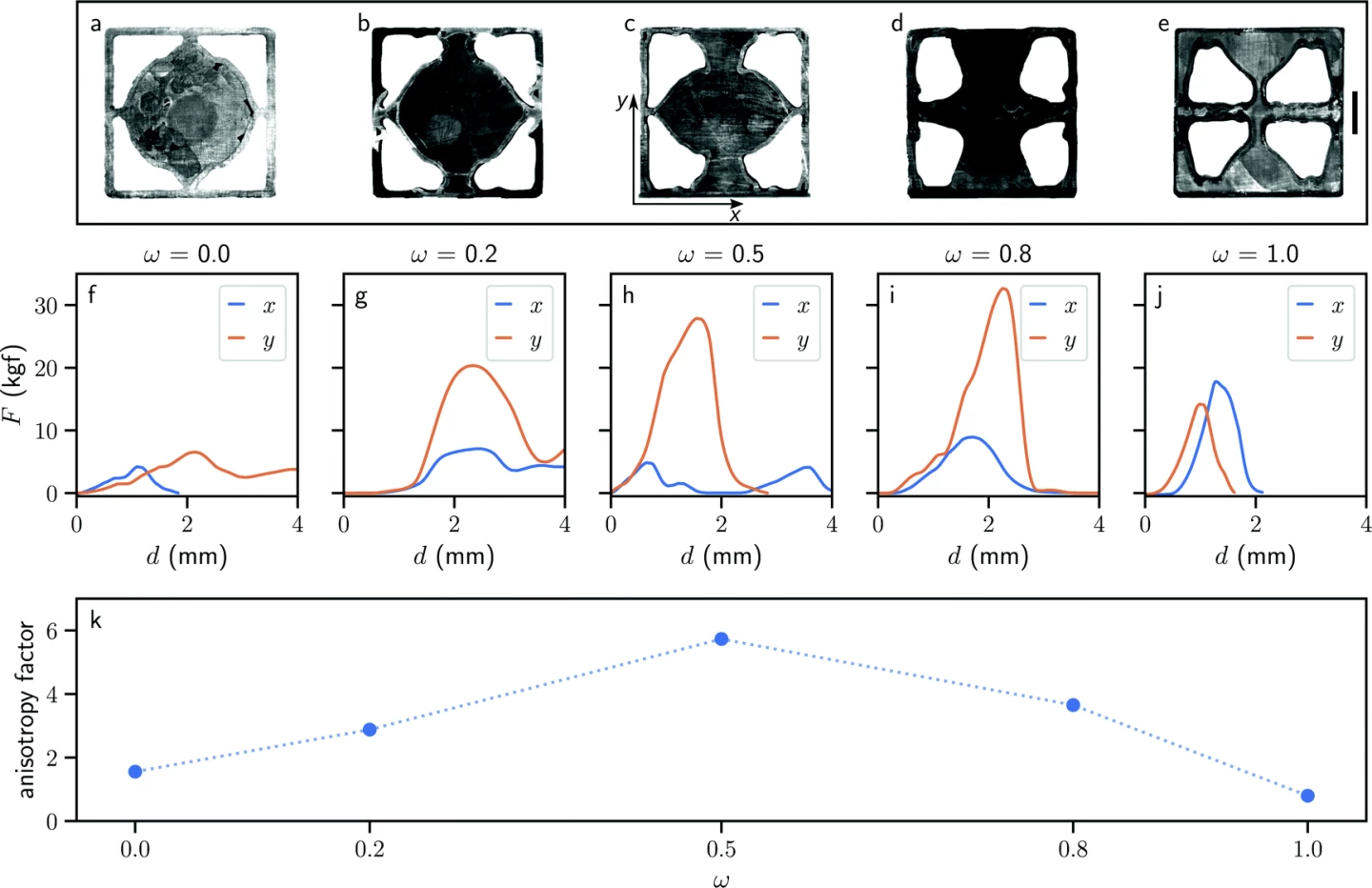

They then started to experiment with "maximally anisotropic structures" – designs that are strong if bitten in one direction, but brittle and crackly in another, coming up with a series of other interesting-looking patterns.

In order to create these research-grade chocolates, the team had to make this notoriously difficult material work in a 3D printer while ensuring it was properly tempered to maximize the formation of those precious phase V crystals. To do so, they heated the chocolate to 45 °C (113 °F) to destroy all its crystals, then let it cool, adding solid pellets of pre-tempered chocolate to "seed" phase V crystal formation, until it dropped below 34 °C (93 °F), the melting point of phase V crystals.

At this point, they loaded the chocolate into syringes, and put those into cartridges for a 3D Bioplotter, which were kept at 32 °C (90 °F). Then, they printed their shapes, layer by layer, onto a printing base kept at 12 °C (54 °F), with a fan circulating air to encourage the chocolate to solidify as quickly as possible, ready for the next layer.

They ran into trouble; the chocolate started to crystallize in the tube of the syringe, so the machine had to be constantly re-calibrated as the thickness of the printed lines changed. It also thickened as a print went on, requiring significant adjustments to pressure and speed as each print progressed, and every time a line stopped or started, there were inconsistent chocolate drops left on the nozzle, further confounding any attempt at total uniformity between samples.

So while the team made some progress toward discovering which chocolate designs were most interesting and crackly and enjoyable to eat, there's clearly a lot more work to be done towards designing a 3D printing system that could reliably manufacture the designs in high-grade tempered chocolate.

The paper was published in the journal Soft Matter.

Check out a short video below.

Source: University of Amsterdam