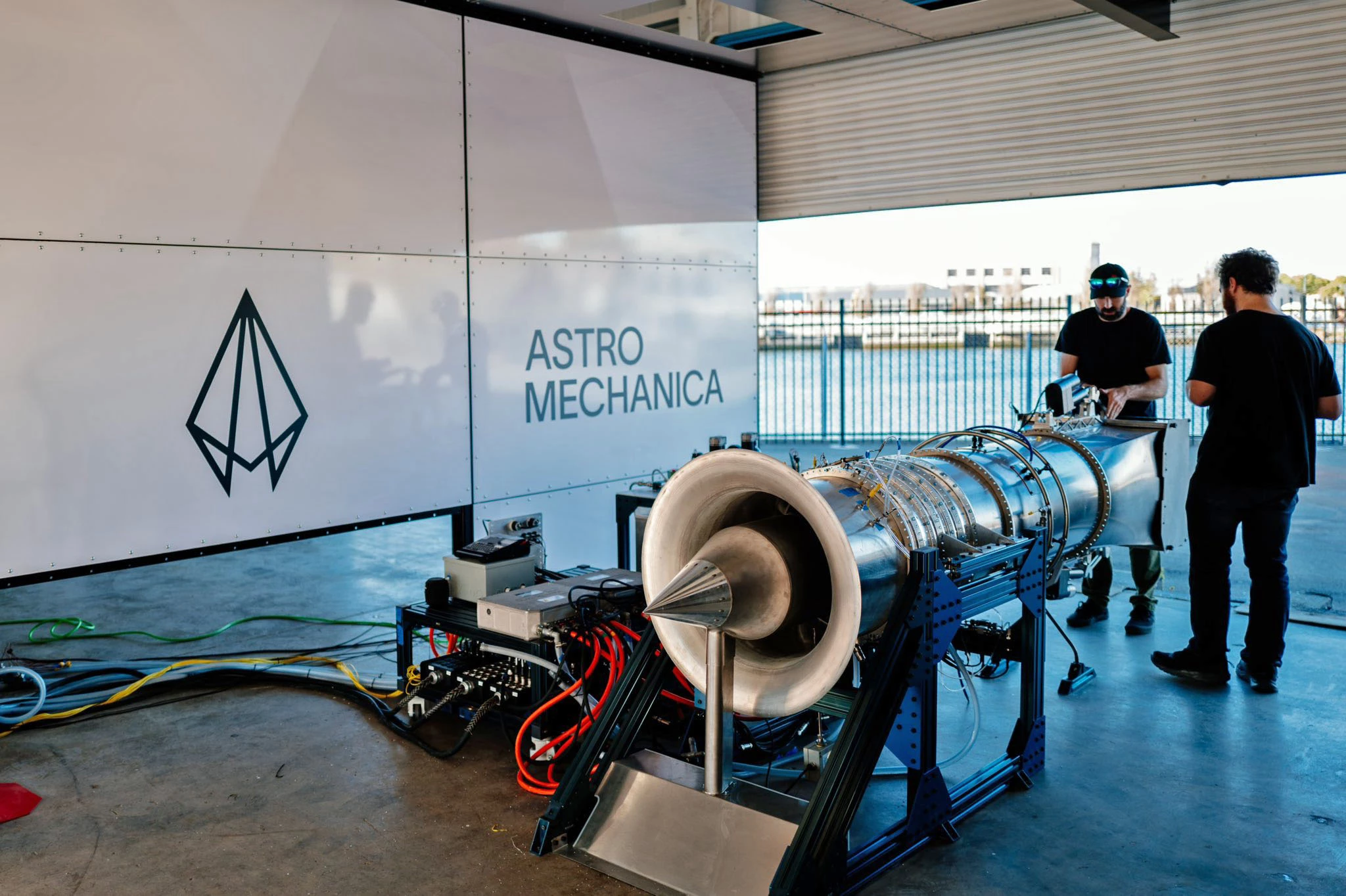

Astro Mechanica – founded in 2021 by Ian Brooke and with a tight ship of only eight employees – is an aerospace startup developing what it calls a turboelectric adaptive engine for both subsonic and supersonic flight ... with electric car motor technology.

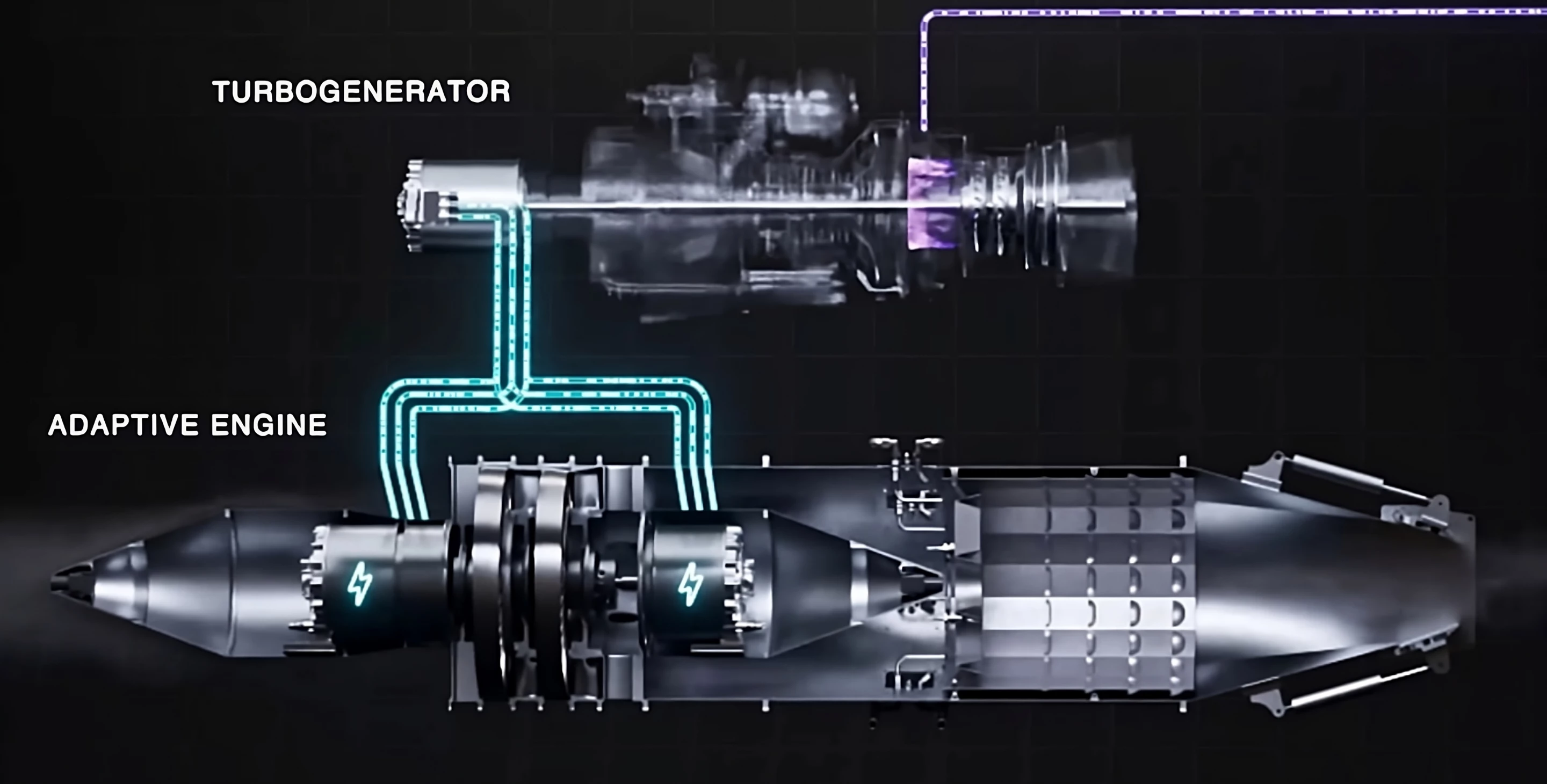

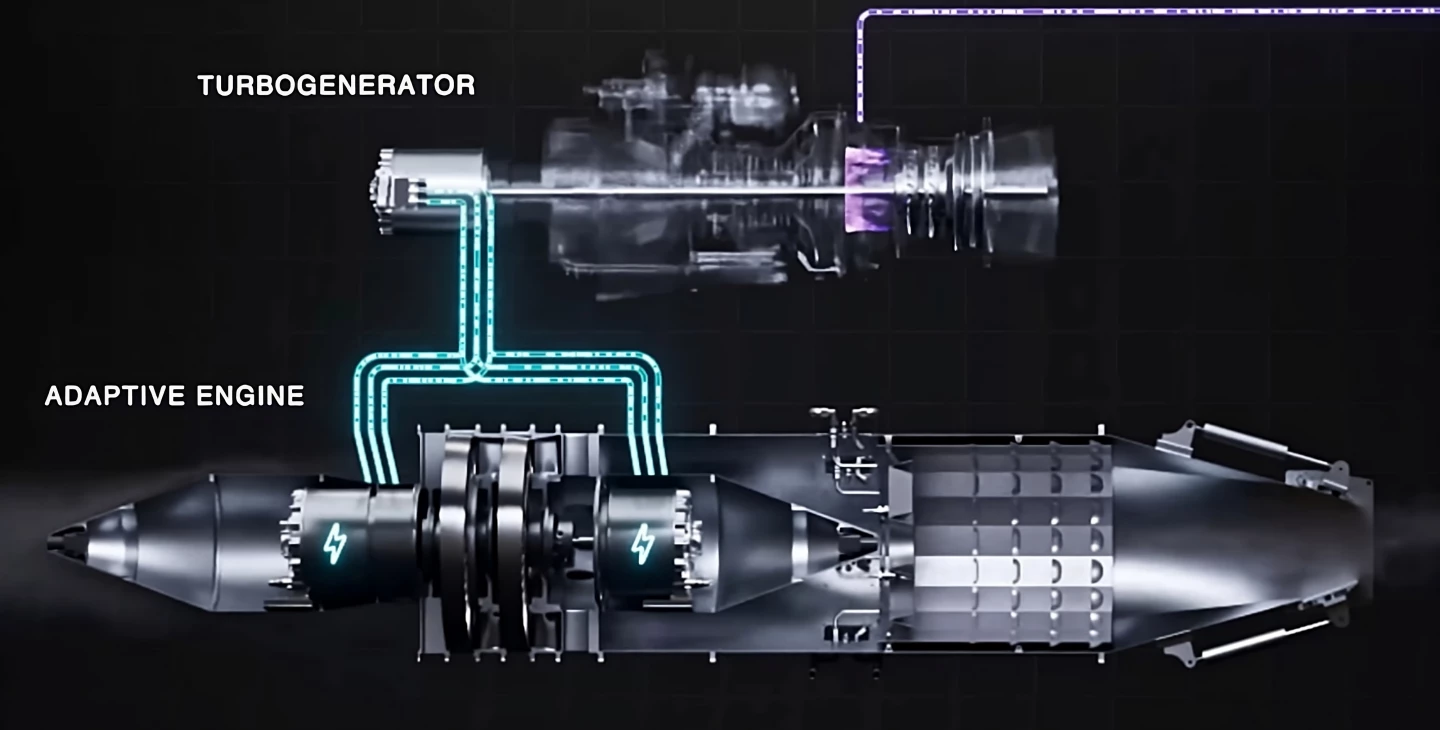

The turboelectric adaptive engine is designed to behave like a turbojet or a turbofan in a single unit. As the engine is divided into two parts, with a turbogenerator driving an electric motor to produce electricity to power a second set of electric motors that drive the compressor and turbofan independently, the engine can vary the amount of air being compressed and therefore the volume of compressed air that's available for combustion.

That might sound complicated, but it's actually quite genius, splitting the fan and compressor components and mechanically driving the compressor independently with high-performance electric motors similar to those being used in the EV market today.

On October 11, 2024, Astro Mechanica successfully performed the first hot-fire test up to 30% power of its Gen3 engine.

Traditional turbojets, like you'd see in fighter planes, use the exhaust gas to spin the compressor fan to draw in air. More exhaust equals more speed. And a turbojet is efficient at supersonic high speeds – slow speeds, not so much. The turbojet struggles to compress enough air for efficient combustion and wastes significant amounts of fuel.

The Concorde, for example – a supersonic commercial passenger aircraft in operation from 1976 to 2003 – was notorious for its fuel inefficiencies. It's was said to use around 2 tons (627 gallons / 2,372 liters) of fuel just to taxi to the runway from the gate, highlighting how incredibly inefficient turbojets are at low speed.

A turbofan engine, on the other hand, is designed to move huge amounts of air to propel an aircraft forward. At lower subsonic speeds, it does this quite well. Faster than that, aerodynamic drag created by the large fans that aren't optimized for fast flight creates an efficiency and operability issue.

Astro Mechanica's engine operates in three distinct modes:

- Mode 1 uses an electric motor to spin the "blisk" – a bladed disk the company makes in-house that acts as the compressor/turbofan instead of traditional fan blades – without active combustion, perfect for efficient ground operations and subsonic flight.

- Mode 2 introduces turbojet combustion, propelling the aircraft past the speed of sound while an electric motor powers the compressor to the necessary speeds to feed the engine enough air, rather than relying on exhaust gases like a traditional turbojet engine.

- Finally, Mode 3 is an all-fuel ramjet-like configuration with no moving parts, allowing the engine to potentially reach Mach 3 or faster using only the Ram Pressure effect, where the aircraft's speed forces an immense amount of air into the inlet, providing enough compression for combustion.

With this design approach, Brooke reckons the Concorde would have had 61% more range if it were fitted with the Astro Mechanica turboelectric adaptive engine.

Standby: Engine loading in progress... pic.twitter.com/oPwtgPCvQV

— Astro Mechanica (@AstroMechanica) June 8, 2024

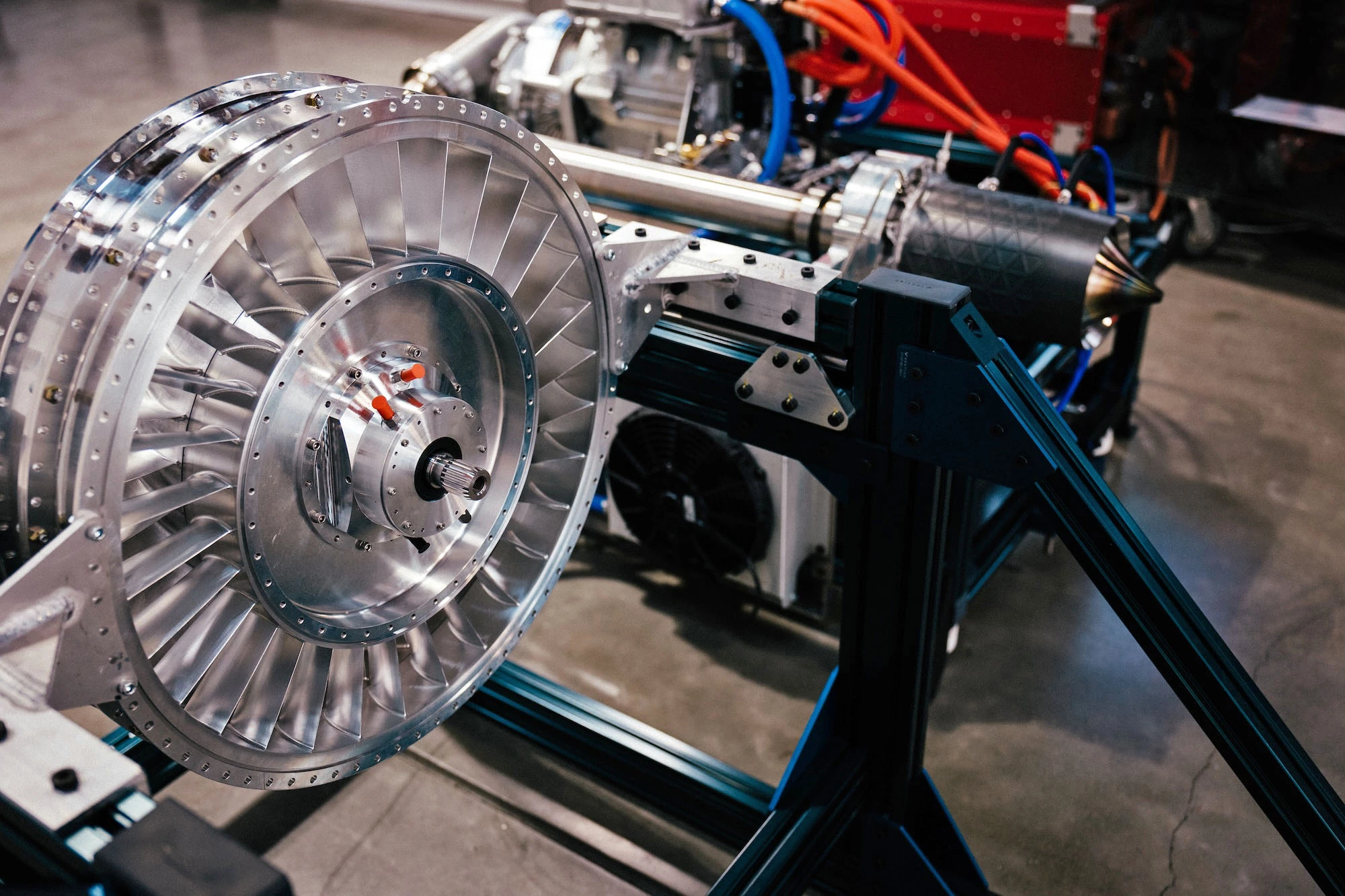

About 60 hours of CNC milling goes into making a "blisk" as you can see above.

A smaller, Gen 1 prototype engine already demonstrated an astonishing velocity of 900 m/s (2,013 mph / 3,240 km/h or about Mach 3).

I've kept a pretty low (online) profile of what I'm building, but word's getting out.

— Ian Brooke (@k2pilot) February 29, 2024

My company Astro Mechanica has invented a new kind of jet engine. Unlike any existing engine, it's efficient at every speed. Because it's efficient at every speed, we can use it in a new way:… pic.twitter.com/YecrslCiPZ

Cost-effectiveness is also a major focus of Astro Mechanica's approach. The CFM LEAP-1B engine found in a Boeing 737 MAX costs around US$14 million per engine. Astro Mechanica claims its turboelectric adaptive engines would be significantly less expensive, already supersonic-capable, have fewer moving parts, and likely be cheaper to maintain. Moreover, the engines are designed to run on liquid natural gas (LNG), which is 1/10th the price of traditional jet fuel, offers more energy per unit weight, and produces 30% less CO2 when burned.

The engine can also run on synthetic methane, notes Brooke, making it adaptable to potential future fuels. Synthetic methane can be created as a sustainable fuel with CO2 and hydrogen in a process called methanation.

In the near-ish future, Brooke intends to build an experimental airframe powered by four Astro Mechanica turboelectric adaptive jet engines and two GE CT7 engines and flying non-stop-supersonic from San Francisco to Tokyo, collecting data, to really ramp up the company's place in aerospace engineering.

Source: Astro Mechanica