Honda doesn't just want to power future vehicles with solid-state batteries; the company wants to develop and ultimately mass-produce the batteries itself. Solid-state tech represents a deep-anchored cornerstone of both its midterm electric vehicle plans and its greater goal of achieving full carbon neutrality by 2050. It took a big step toward those objectives this month, unveiling its first demonstration solid-state production line, which will allow it to refine both the battery construction and the manufacturing processes behind it.

Like other automakers and battery suppliers, Honda realizes that solid-state technology has the potential to directly address the biggest problems facing today's electric vehicles. First and foremost, it will work to leverage solid-state's superior energy density toward batteries that supply double the range within the same size footprint as modern lithium ion-powered EVs, providing up to 620 miles (1,000 km) per charge by the end of the decade.

Since not every driver needs that much range, Honda will also rely on the superior energy density to decrease battery size and weight in some cars, allowing for more design flexibility and more spacious interior layouts. In addition to cutting battery size by 50% for the same amount of energy as a lithium-ion pack, the company estimates weight-saving potential at 35%.

Honda also cites lowered costs, increased charge/discharge rates, shored up stability and safety, and improved overall durability as target advantages of its solid-state battery program.

If those advantages are realized, solid-state batteries will underpin a new generation of Honda EV that can compete with and downright outshine ICE vehicles in critical areas like price and everyday driving convenience. Honda aims to launch the first solid-state-powered EVs in the second half of the 2020s as it works toward offering a lineup consisting exclusively of battery electric and fuel cell electric vehicles by 2040.

Given how much importance Honda places on solid-state batteries, it's not surprising to see it pushing for more vertical integration, bringing solid-state battery development in-house with the intention of manufacturing its own units. Doing so will help it achieve a targeted 25% battery cost reduction, the company estimates.

Honda took a major step in its ambitious solid-state roadmap last Thursday (Nov. 21st), when it unveiled a demonstration production line at its R&D campus in Sakura City, Japan. It will use the line to develop and verify both the specifications of solid-state battery cells themselves and the mass production processes behind them, helping to shorten the overall development timeframe and ensure its batteries work within a production system, not just in a lab.

"It is possible to develop a small battery while focusing on the performance of materials rather than restrictions of mass-production methods; however, for commercialization, it is important to develop batteries while envisioning future mass-production methods, which will enable our batteries to meet the requirements for each model, such as size and cost," Honda writes about its solid-state strategy.

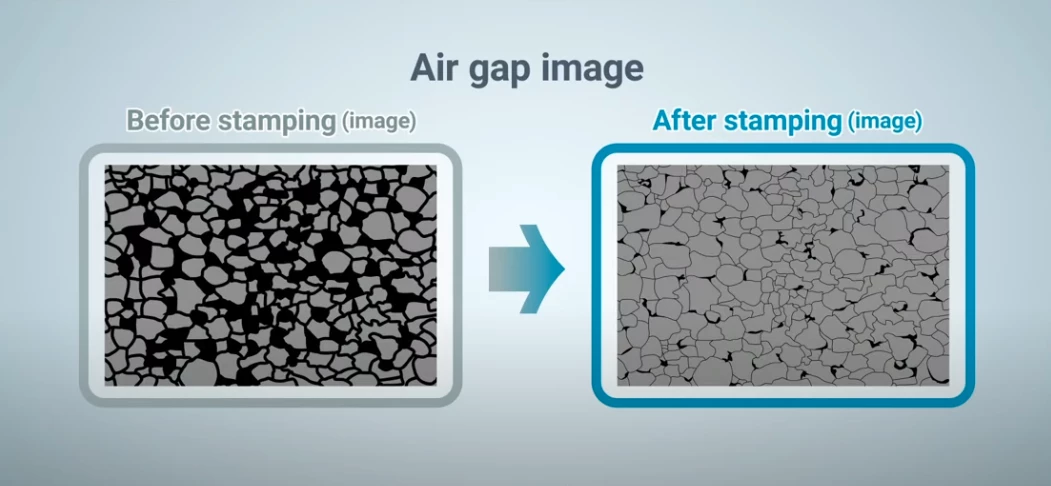

"The size and structure of electrodes and a specific stamping method required for all-solid-state batteries affect each other in terms of performance, cost, and quality. Therefore, we are conducting research to achieve compatibility between material specifications and production method specifications for batteries of a certain size."

The construction of the new three-building battery production line was completed in the spring, and Honda has now added nearly all the equipment and tooling it needs to begin verifying mass production techniques. It will use the new 295,000-sq ft (27,400-sq m) facility to verify production steps around weighing and mixing of electrode materials, coating and roll-pressing of the electrode assembly and formation of cells, and assembly of the module.

Honda views the roll-pressing aspect as particularly critical, stressing that the method increases the solid electrolyte density while also increasing interfacial contact between the electrolyte and electrode, both important factors in battery performance. At the same time, the technique ensures the high-speed processing necessary for mass production, allowing each electrode and cell assembly to quickly roll through and onto the next steps.

"The all-solid-state battery is an innovative technology that will be a game changer in this EV era," said Honda R&D president and director Keiji Otsu. "We will continue taking on challenges to launch our mobility products equipped with our all-solid-state batteries as quickly as possible so that Honda can offer new value to our customers."

The broader term "mobility products" foreshadows solid-state battery tech playing a key role in future Honda products beyond cars and trucks. The company points specifically to motorcycles and aircraft as two other product lineups poised to benefit from the new technology and help achieve the economies of scale necessary to further drive down battery costs.

Honda plans to officially switch on the new demonstration production line in January 2025.

Source: Honda