"Hypersaline brine" is industrial waste-water with salt levels that exceed even that of seawater. It's a big, expensive, destructive problem which a team of engineers at Columbia University in New York City hope to solve with their solvent-based method of desalination.

A by-product of oil and gas production, fossil-fueled power plants, flue-gas desulfurization, landfill leaching, industrial effluent and inland desalination, hypersaline brines are difficult and expensive to treat and if mismanaged, they can cause severe damage to surface and groundwater sources. Having an effective, affordable method for dealing with these brines could make huge quantities of water available for agriculture and industrial uses, and even as a possible source of drinking water.

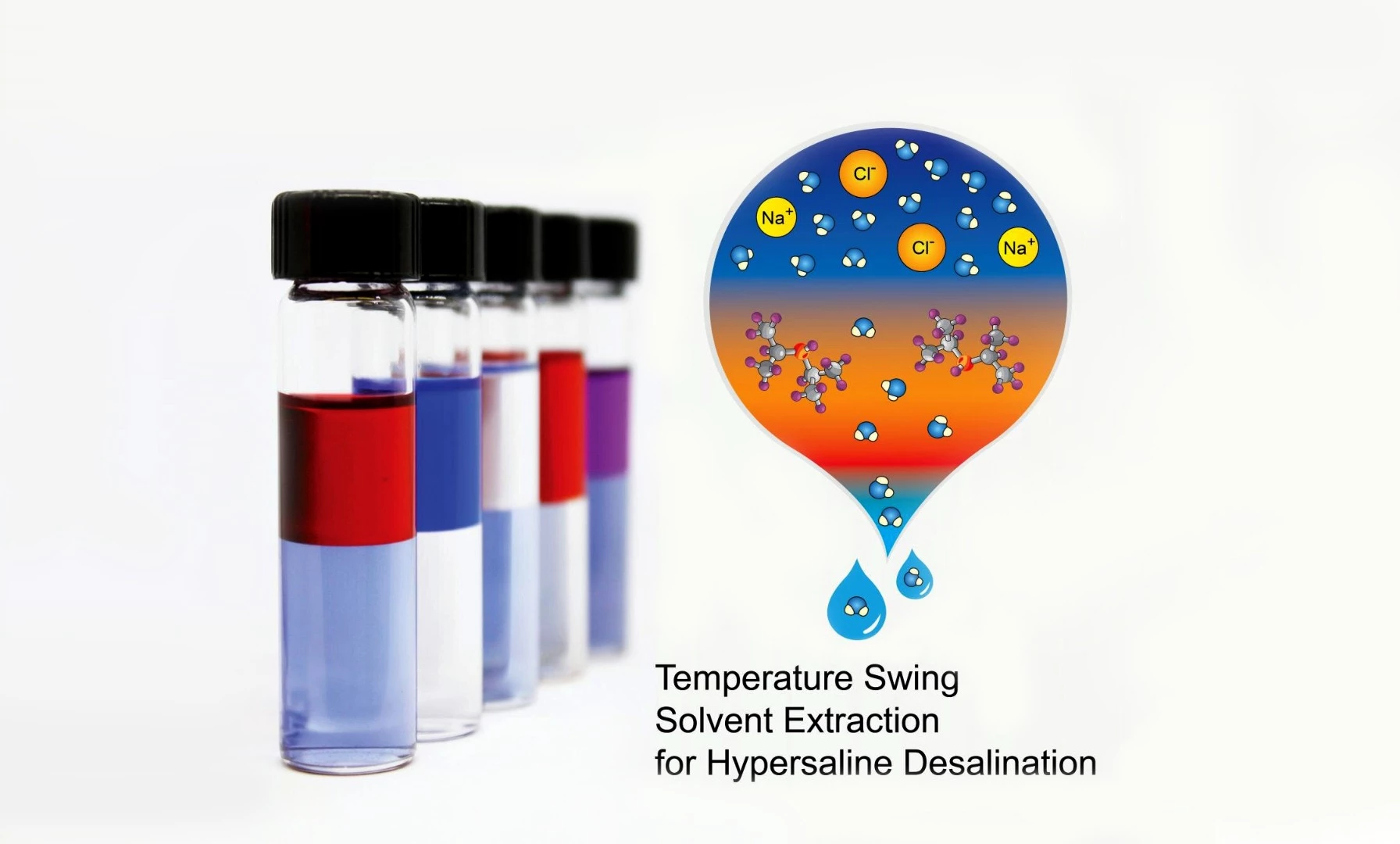

With these challenges in mind, engineers at Columbia University in New York City, have devised a solvent-based method of extracting fresh water from these brines which is efficient, effective and low-cost, and which they've dubbed "temperature swing solvent extraction" or TSSE.

There are two primary methods of desalination of hyper saline brines currently employed – reverse osmosis and distillation. Reverse osmosis is fine for water with low-salt concentrations, but for hypersaline brines, the high pressure required is very expensive and energy intensive. Distillation, which evaporates the brine, also requires a prohibitive amount of energy.

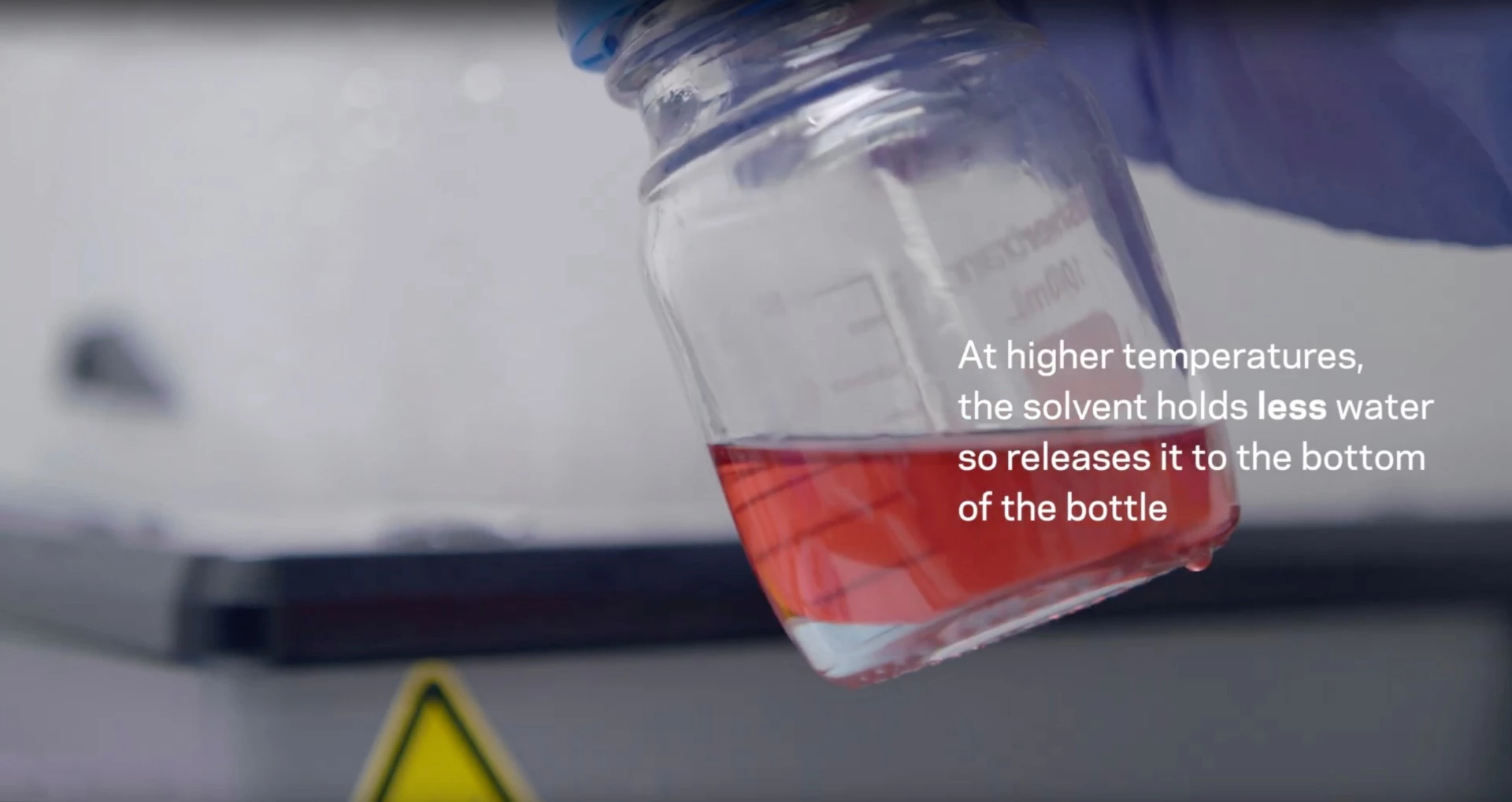

In contrast, the TSSE method – developed by a Columbia Engineering team led by assistant professor Ngai Yin Yip – is beautifully simple. It uses a solvent with temperature-dependent water solubility. Vary the temperature, and you vary the solubility. This solvent is added to the brine, where it floats above the denser salt-laden liquid. At room-temperature, water from the brine is drawn into the solvent. After this stage, the solvent is drawn off and warmed via low-grade heat under 70° C (158°F). The "temperature swing" nature of the solvent subsequently demixes it from the water (remember, this is a temperature-dependent solvent, where at higher temperatures, it holds less water). The resulting desalinated water then settles to the bottom, and is collected.

"I thought solvent extraction could be a good alternative desalination approach that is radically different from conventional methods because it is membrane-less and not based on evaporative phase-change," Yip says. "Our results show that TSSE could be a disruptive technology – it's effective, efficient, scalable, and can be sustainably powered."

And speaking of sustainability, the low-heat requirements for the process is one of its most appealing elements. Depending on the location of the technology, this low, sub 70° C heat can be supplied conventionally at low cost, or sustainably from sources such as low-concentration solar, on-site waste heat from industrial processes or shallow-well geothermal.

"We think TSSE will be transformational for the water industry," says Yip. "It can displace the prevailing practice of costly distillation for desalination of high-salinity brines and tackle higher salinities that RO cannot handle. This will radically improve the sustainability in the treatment of produced water, inland desalination concentrate, landfill leachate, and other hypersaline streams of emerging importance. We can eliminate the pollution problems from these brines and create cleaner, more useable water for our planet."

The Columbia study has shown that TSSE is able to desalinate brines with up to seven times the salinity of seawater. This is a vast improvement on reverse osmosis, the current gold-standard for desalination.

A recent United Nations University paper entitled UN Warns of Rising Levels of Toxic Brine as Desalination Plants Meet Growing Water Needs speaks to the urgent need to deal effectively with hypersaline brines created in the production of potable water, stating that for each liter of freshwater these plants produce, 1.5 liters of brine is also created. Globally that's 142 million cubic meters of hypersaline brine per day, or – over a year – enough to cover Florida in a foot (30 cm) of brine. This of course excludes the hypersaline brines resulting from other industrial activities, which make the problem even more urgent.

The paper by the team at Columbia, was published in Environmental Science & Technology Letters. A short demonstration of the technique can be seen in the video below.

Source: Columbia University School of Engineering and Applied Science