A wildly innovative turbine that could halve the cost of offshore wind is set to go into testing in Norway. The 19-m (62-ft), 30-kW, contra-rotating vertical-axis turbine is a prototype of a design that could scale to unprecedented size and power.

Most wind turbines look like a propeller on a stick – which is fine, except once you take the concept out into the deep ocean, where the vast majority of the world's best wind power resources are, and scale it up, it's a design that makes less and less sense. All the heavy bits are right up the top, so it's difficult and expensive to build and maintain a floating version that doesn't want to tip over in the wind.

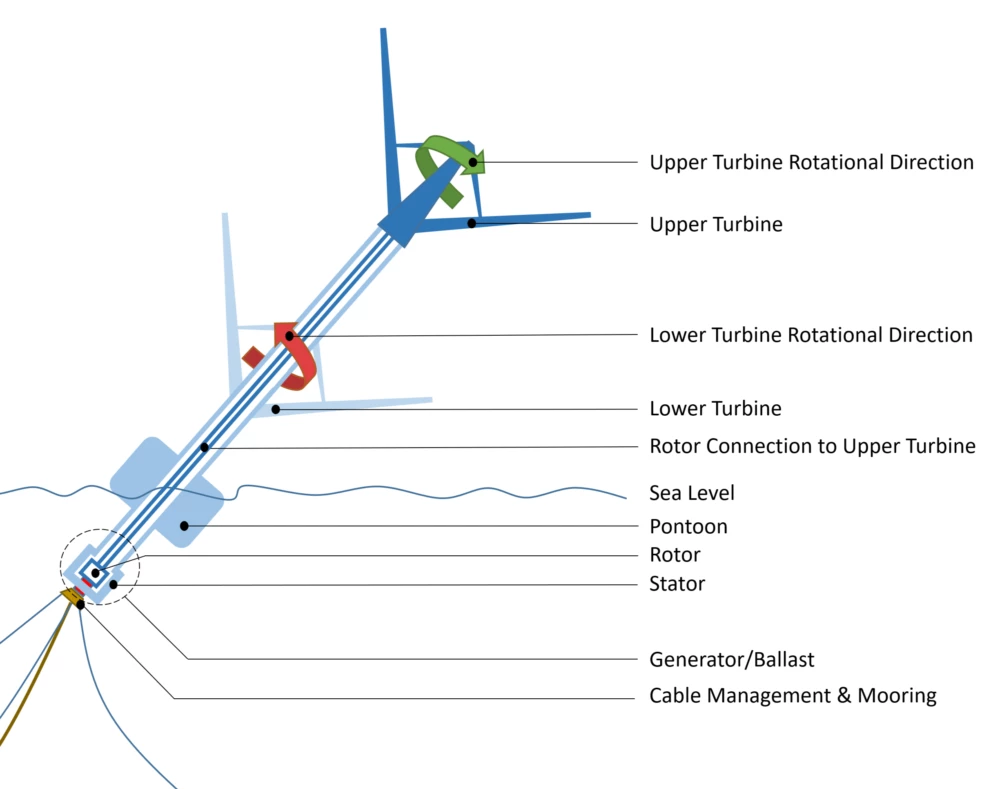

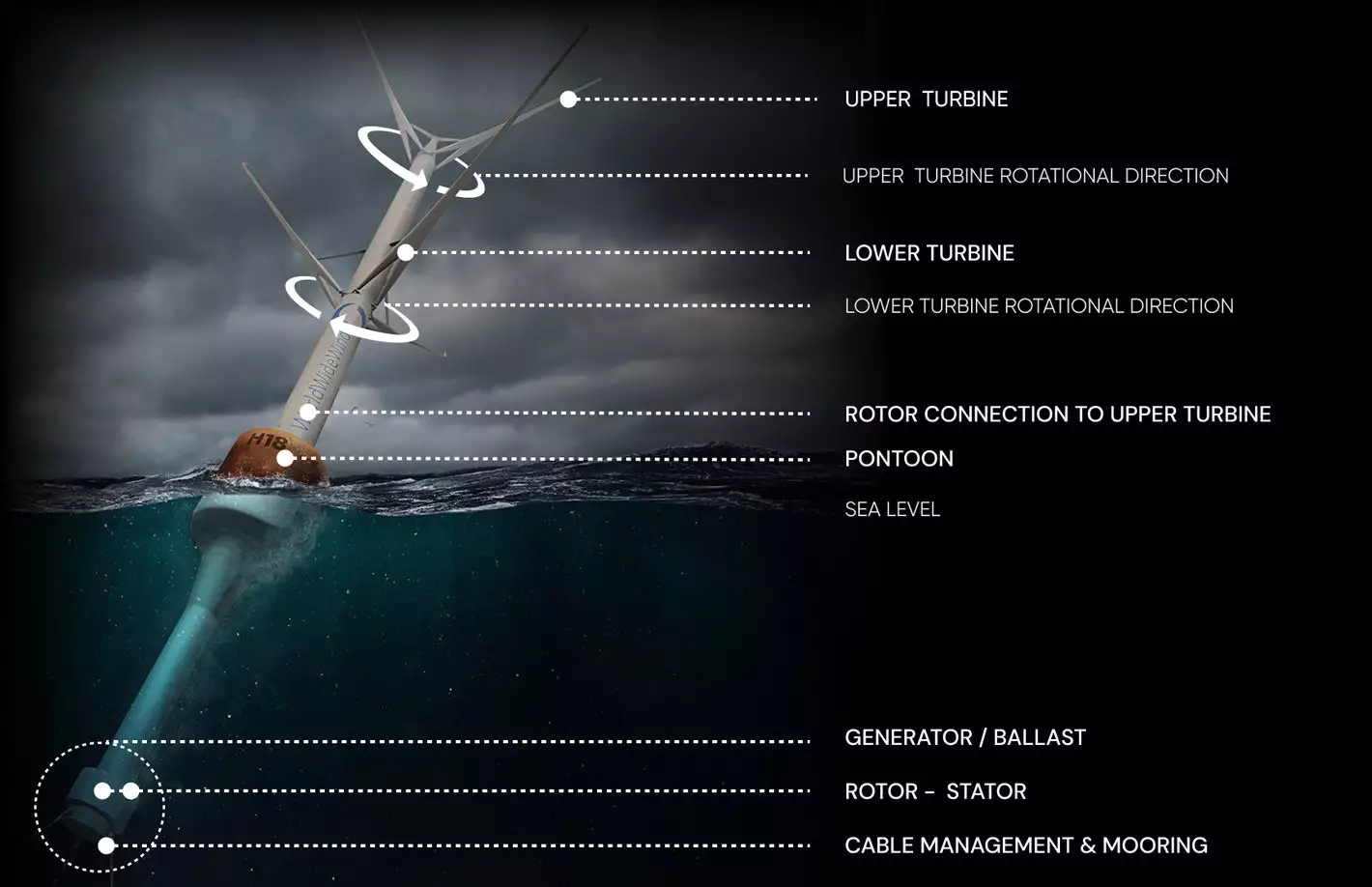

That's what makes World Wide Wind (WWW)'s contra-rotating VAWT such a fascinating alternative. All the heavy generator business is kept right at the bottom – indeed, under water and below the turbine's floating pontoon. That adds enough weight at the bottom to keep the whole thing from topping into the water, requiring only a set of mooring anchors.

The generator's rotor and stator are then connected to a pair of vertical-axis turbines, each running three blades at 45 degrees from the main tower shaft. The lower turbine is set to rotate in one direction, and the upper one, mounted on a pole that runs up the middle of the lower one, is set to rotate in the other direction.

The blades are simple and fixed, and harvest useful torque from the wind most of the way around, much like sailboats can.

"The only time it will not catch speed is when it's going directly upwind, or directly downwind," WWW CTO Hans Bernhoff told us in an interview last year. "As a vertical axis blade goes around, it more or less gets torque on 300 degrees of the 360."

The generator resistance can be managed by the microsecond to control the speed of the turbine.

Thus, whichever way the wind's blowing, the floating double VAWT passively tilts to an optimal angle, and the two turbines begin turning in opposite directions, effectively doubling the speed at which the "rotor" is turning in the "stator."

"You can think of that as a way to double your power generation, or as a way to reduce your generator cost by half," former WWW CEO Trond Lutdal told us. "So it's lower cost, it's much more scalable, and any maintenance happens at the bottom and not hundreds of feet up in the air."

The torque placed on the structure by the wind is effectively neutralized by the two opposing rotations. On top of this, the conical sweep of each rotor reduces blade tip speed, and produces less of a wake effect behind it, so in a practical wind farm situation, the company says they can be deployed closer together, generating more energy from a given area and reducing connection cabling.

Using some interesting materials choices, WWW says it sees a clear path to scale these machines up to a monstrous 400 m (1,312 ft) tall, at which point a single tower could harvest an enormous 40 MW – nearly twice what the world's largest wind turbines can do – and more importantly, it could massively drop the Levelized Cost of Energy (LCoE) for offshore wind to less than US$50/MWh – that's less than half the cost of what regular horizontal-axis towers are shooting for by 2027.

So they're a very exciting prospect, as well as a fascinating thing to look at, which is why we're happy to hear the team has signed an agreement to begin testing a small-scale prototype in partnership with AF Gruppen, one of Norway's largest industrial construction groups.

The 19-m prototype will be tested at AF's Envinronmental Base in Vats, nestled deep in the hills, on the banks of a fjord, off a fjord, off a fjord, off a fjord, on the heartbreakingly beautiful southeast Norwegian coast. Right among Slartibartfast's greatest and most fiddly work.

While there's no timetable laid out for this test, the company says its next prototype will be a much larger 1.5-MW pilot, scheduled to begin testing in early 2025 – and it hopes to launch a commercial 24-MW turbine before 2030, which would be the world's largest offshore turbine by a decent margin if it launched today.

“We are very proud to test our first prototype in cooperation with AF Gruppen,"says Bjørn Simonsen, new CEO of WWW, in a press release, "and look forward to the launch and subsequent test program, as well as exploring further opportunities for collaboration. We very much appreciate the support we have received from the AF team so far and are very grateful that they are letting us use their yard at Vats for the test."

Bring it on! If these massive machines do what they say on the tin, the world needs them yesterday.

Source: World Wide Wind