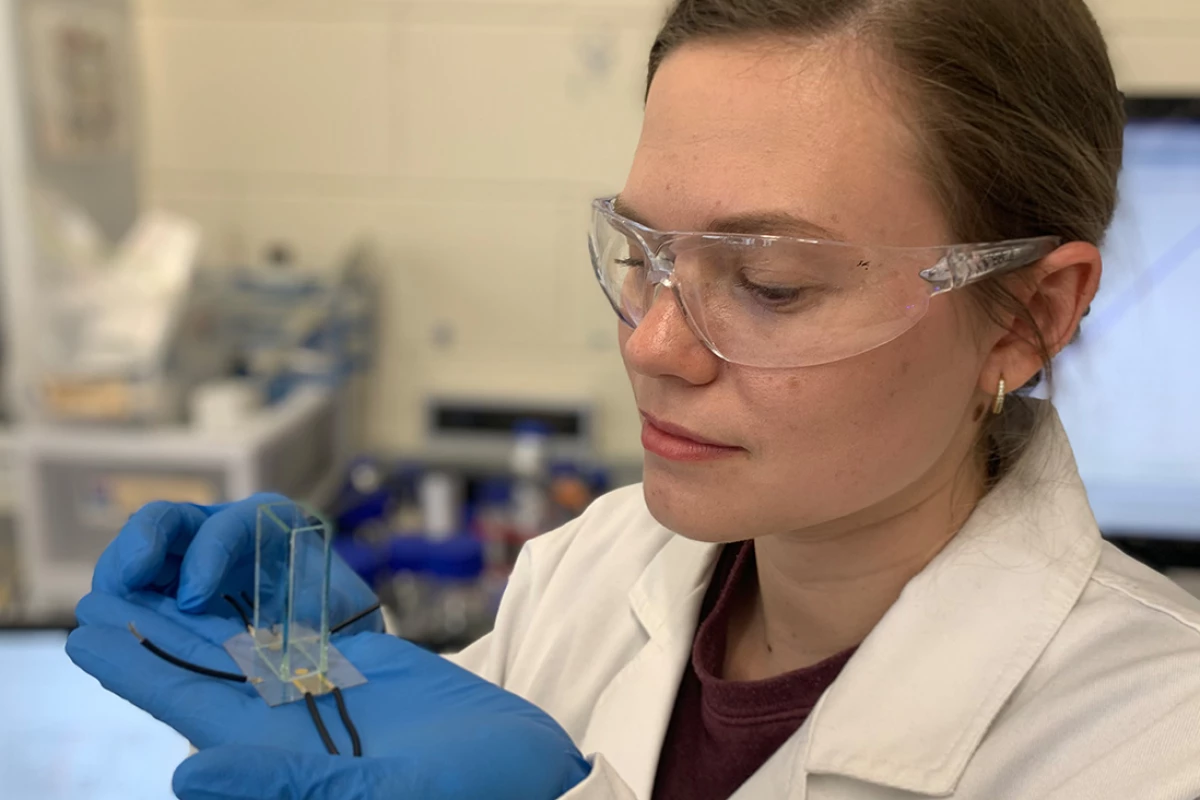

RMIT researchers say they've unlocked cheaper, more energy-efficient green hydrogen production with a new electrolysis technique boosted by sound waves. With these high-frequency vibrations active, standard electrolysis produces 14x more hydrogen.

Where batteries can't carry enough energy, or take too long to charge, green hydrogen is rising as an important zero-emissions fuel that carries a higher density of electrons and supports fast refueling. Green hydrogen is created through electrolysis; splitting water molecules into hydrogen and oxygen using renewable energy to attract each gas to a different electrode, where the hydrogen can be captured, compressed and stored.

So why does this process work so much better when the RMIT team plays a 10-MHz hybrid sound wave? Several reasons, according to a research paper just published in the journal Advanced Energy Materials.

Firstly, vibrating the water has the effect of "frustrating" the water molecules nearest to the electrodes, shaking them out of the tetrahedral networks they tend to settle in. This results in more "free" water molecules that can make contact with catalytic sites on the electrodes.

Secondly, since the separate gases collect as bubbles on each electrode, the vibrations shake the bubbles free. That accelerates the electrolysis process, because those bubbles block the electrode's contact with the water and limit the reaction. The sound also helps by generating hydronium (positively charged water ions), and by creating convection currents that help with mass transfer.

In their experiments, the researchers chose to use electrodes that typically perform pretty poorly. Electrolysis is typically done using rare and expensive platinum or iridium metals and powerfully acidic or basic electrolytes for the best reaction rates, but the RMIT team went with cheaper gold electrodes and an electrolyte with a neutral pH level. As soon as the team turned on the sound vibrations, the current density and reaction rate jumped by a remarkable factor of 14.

So this isn't a situation where, for a given amount of energy put into an electrolyzer, you get 14 times more hydrogen. It's a situation where the water gets split into hydrogen and oxygen more quickly and easily. And that does have an impressive effect on the overall efficiency of an electrolyzer. "With our method, we can potentially improve the conversion efficiency leading to a net-positive energy saving of 27%," said Professor Leslie Yeo, one of the lead researchers.

Between faster reactions, energy savings and much lower cost materials and electrolytes, the team believes its work could help bring down the price of green hydrogen.

The research is open access in the journal Advanced Energy Materials.

Source: RMIT