It’s hard to imagine a world without the lithium-ion batteries that power today’s laptops and mobile devices, but the technology does have its limits. One way scientists are working to break a bottleneck of energy density and greatly extend the battery life of these devices (and many others) is by bringing pure lithium metal into the mix. A new battery architecture from researchers at the University of California San Diego offers a solution to a key drawback of this approach, using sound waves as a way of preventing dangerous growths that cause lithium metal batteries to catch fire and fail.

The reason lithium metal is seen as a “dream material” by some battery researchers is because of its incredibly high energy density. By using this as the anode component in place of the copper and graphite used today, we could theoretically double the capacity of today’s very best lithium batteries. That would mean electric cars that can travel twice as far on a charge, or smartphones that last for days at a time.

So there are plenty of reasons to pursue this as a battery architecture, but lithium metal brings its share of problems, too. As the lithium ions travel between the cathode and lithium metal anode, they do so via a static electrolyte liquid, which causes the lithium to be unevenly distributed and build up on the anode. That leads to the growth of tentacle-like structures known as dendrites, which in turn make the battery degrade quickly, or even cause short circuits and result in the battery catching fire.

We have seen some promising breakthroughs of late that could overcome this problem. One solution from scientists at MIT makes use of a solid electrolyte rather than a liquid one, which avoids the unwanted reactions from the lithium metal. Another we looked at from researchers in Australia this week uses a unique mix of materials to form a protective layer on the surface of the lithium metal anode, which gives the dangerous dendrites no opportunity to form.

The University of California San Diego researchers see the static nature of the liquid electrolyte as one of the key problems with current lithium metal battery designs. To change the nature of this, the team turned to ultrasound, which actually plays a role in today’s smartphones, which use high frequency sound waves to filter cellular signals and filter and identify voice calls or data.

“Advances in smartphone technology are truly what allowed us to use ultrasound to improve battery technology,” says James Friend, a professor of mechanical and aerospace engineering and study co-author.

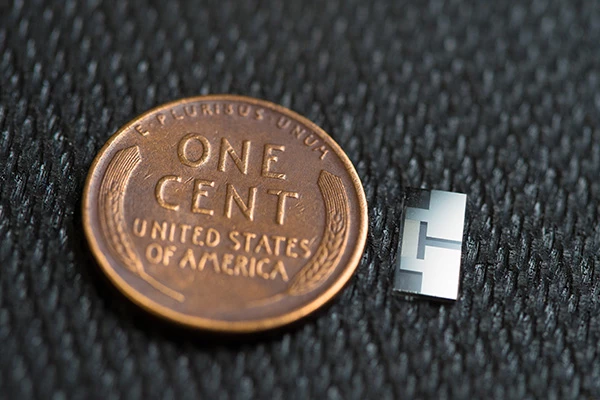

The team took off-the-shelf components to build a tiny ultrasound device and incorporated it into a lithium metal battery. There, it sends high-frequency sound waves ranging from 100 million to 10 billion hertz through the electrolyte liquid, which causes it to flow rather than remain static. Instead of uneven clumps, this leads to neat, uniform deposits of lithium on the anode and avoids the formation of dendrites.

In testing, the team’s lithium metal battery proved stable across 250 charging cycles, and was able to be charged from zero to 100 percent in just 10 minutes.

“This work allows for fast-charging and high energy batteries all in one,” says Ping Liu, professor of nanoengineering and study senior author. “It is exciting and effective.”

While lithium metal batteries were the immediate focus for the research team, they say the ultrasound device could be easily fitted to other battery types, too. They tested it as part of a lithium-ion battery, which lasted for 2,000 cycles, and see huge potential in this area.

“Our next step will be to integrate this technology into commercial lithium-ion batteries,” says Haodong Liu, the paper’s co-author.

The research was published in the journal Advanced Materials.