Concrete is made of a combination of cement, an aggregate such as gravel, and water. If that mixture dries too quickly, then cracks can form within it as it cures. Now, however, scientists have determined that the use of coal-ash spheres can help keep that from happening.

Typically, in order to ensure that poured concrete doesn't dry too rapidly, contractors take measures such as covering it with membranes or spraying it with water.

Doing these things can be a hassle, though, which is why some groups have developed lightweight, porous aggregate materials that initially absorb water and then slowly release it within the concrete matrix. The idea is that by using these, the concrete will dry at a more controlled, uniform rate without having to be covered or sprayed.

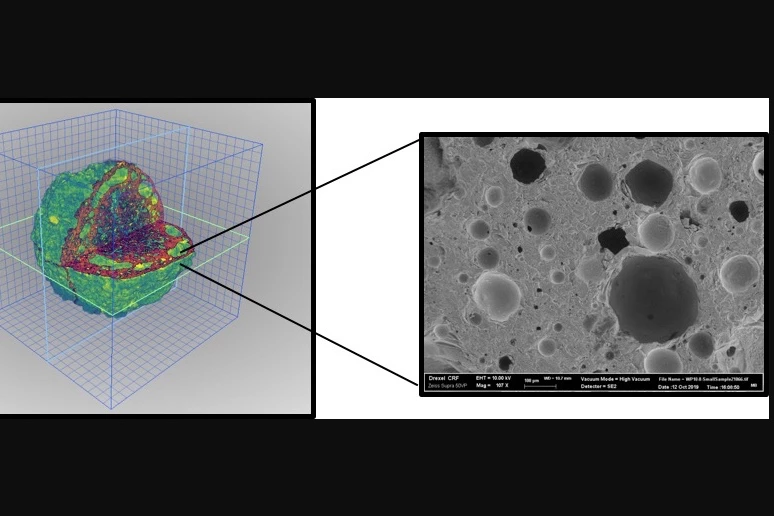

Looking for a cheaper, more abundant form of such porous aggregates, researchers at Philadelphia's Drexel University turned to the "fly ash" waste that is produced when coal is burned at power plants. Led by Asst. Prof. Yaghoob Farnam, they combined the ash with bonding chemicals, formed it into tiny spheres, then baked those spheres at a temperature of 1,160 ºC (2,120 ºF) for a few minutes.

The resulting material is known as SPoRA, which stands for "spherical porous reactive aggregate." Not only is it cheap and easy to manufacture, but it can absorb almost half of its weight in water – this is considerably better than some commercially-available aggregates. That water is gradually dispersed from the spheres and into the concrete matrix as it dries and cures, ensuring that no cracks form.

"The solution we came up with involved recycling this waste product, coal ash, into a porous, lightweight aggregate with excellent performance characteristics that could be produced at a lower cost than current natural and synthetic options," says Farnam. "This material and process would not only benefit the concrete industry by improving the quality of their products, but it could also help keep coal ash out of landfills."

A paper on the research was recently published in the journal Cement and Concrete Composites.

And as a side note, scientists at Rice University previously reported that fly ash could also be used as an eco-friendly alternative to traditional Portland cement.

Source: Drexel University