Auto and motorcycle enthusiasts with a bit of CAD savvy will soon have access to a remarkably affordable dream machine – the US$5,000 MarkForged Mark One. Touted as the world’s first 3D printer capable of printing in carbon fiber, the device could trigger an avalanche of aftermarket carbon fiber bolt-on parts.

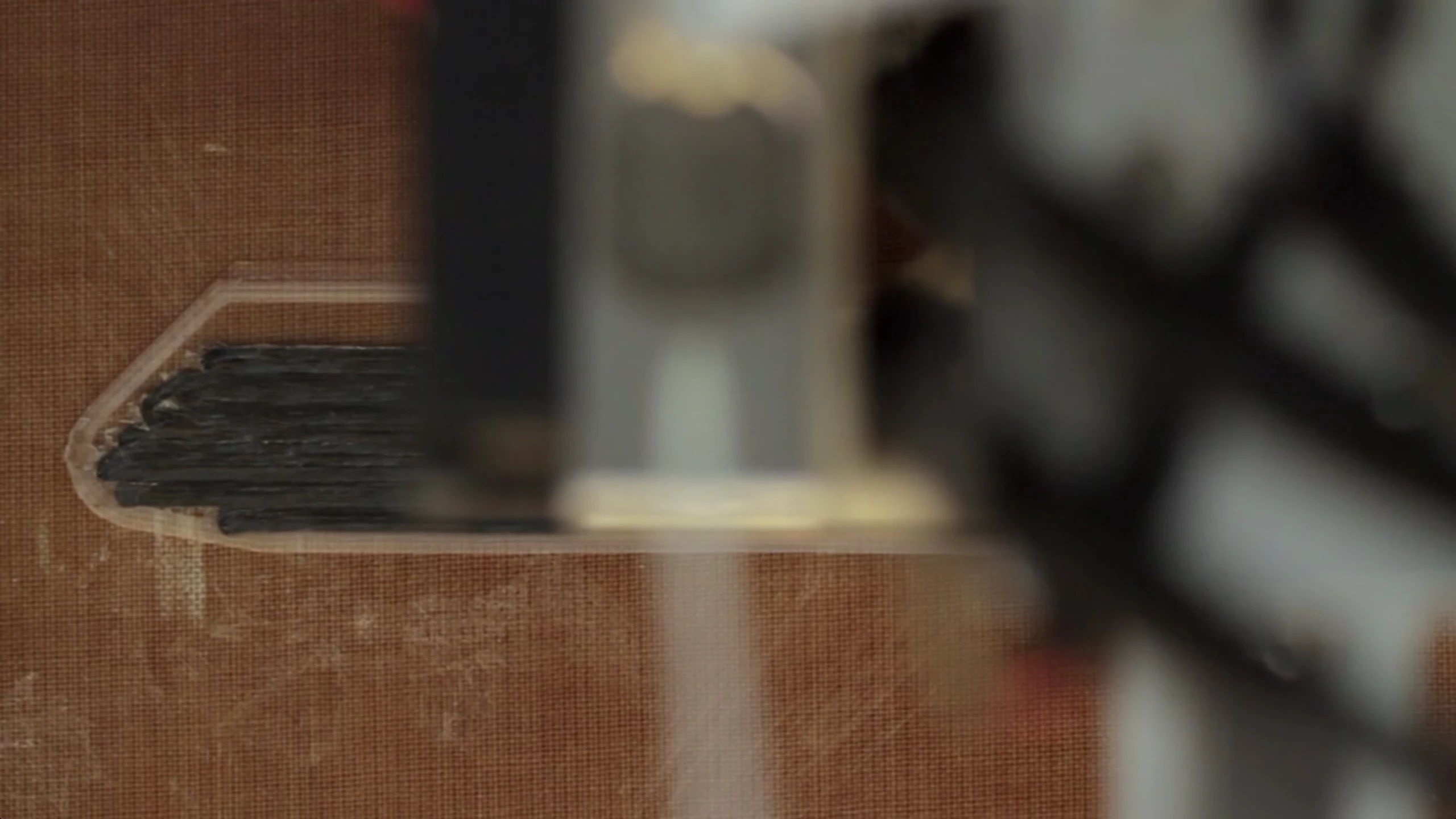

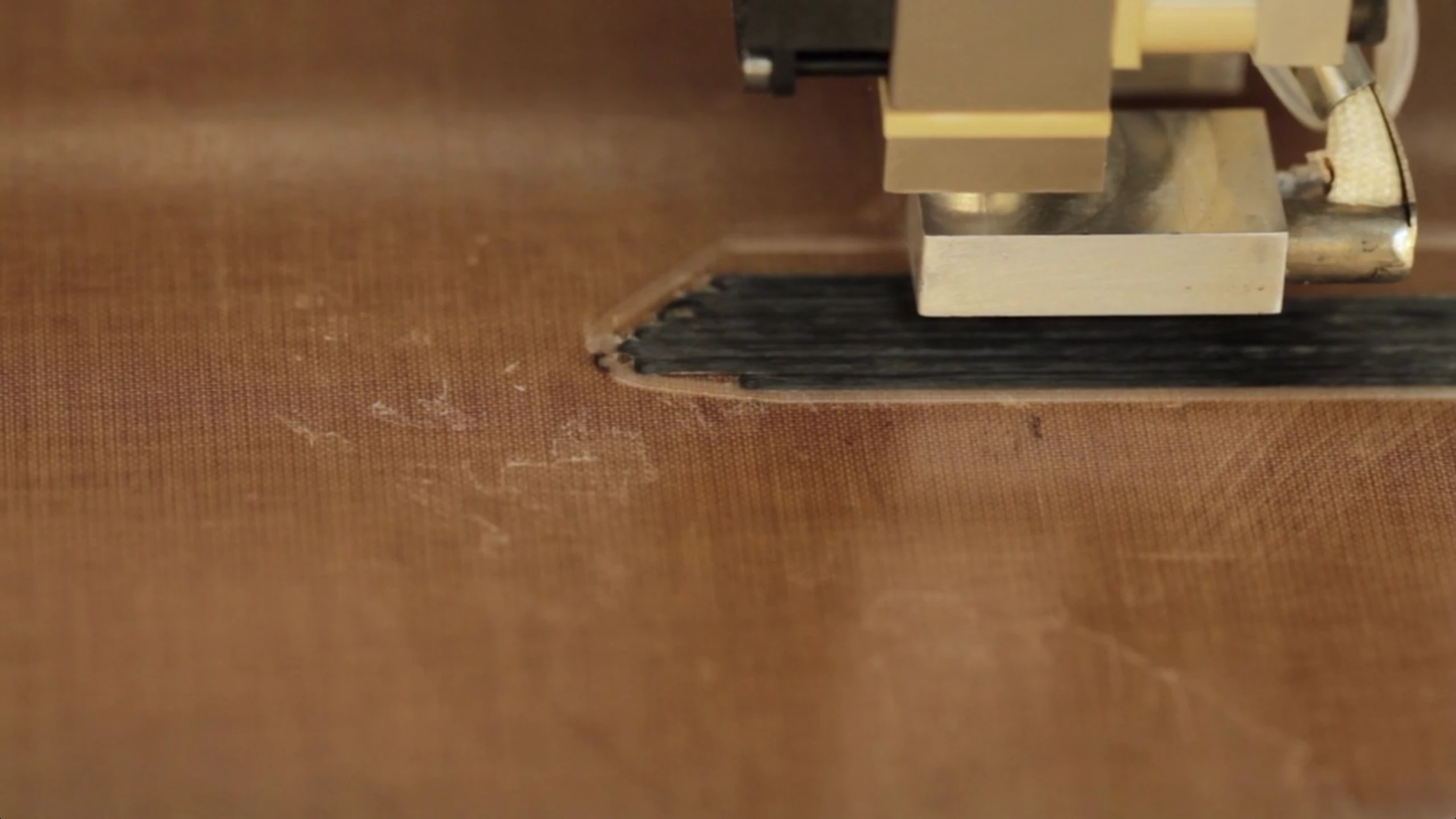

Carbon fiber (CF) has long been a material of choice for automotive and aerospace applications due to its light weight and extreme strength – to the point where its trademark weave pattern has become synonymous with high performance vehicles. Carbon fiber bolt-on parts, or even plastic ones designed to look like CF, are hot items in the aftermarket auto parts industry, and the ability to 3D print such items will presumably open up all sorts of new applications in this and other areas.

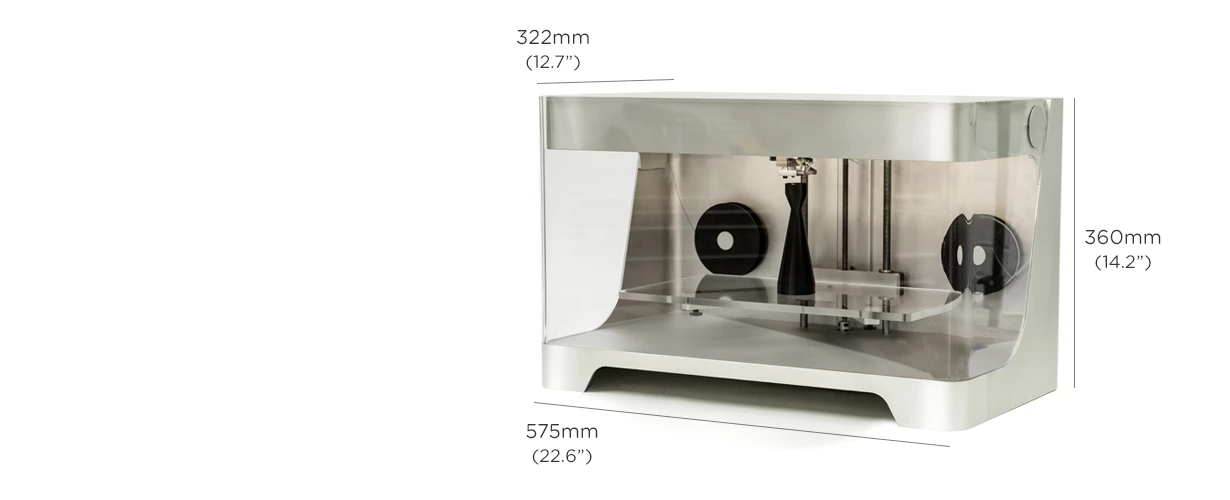

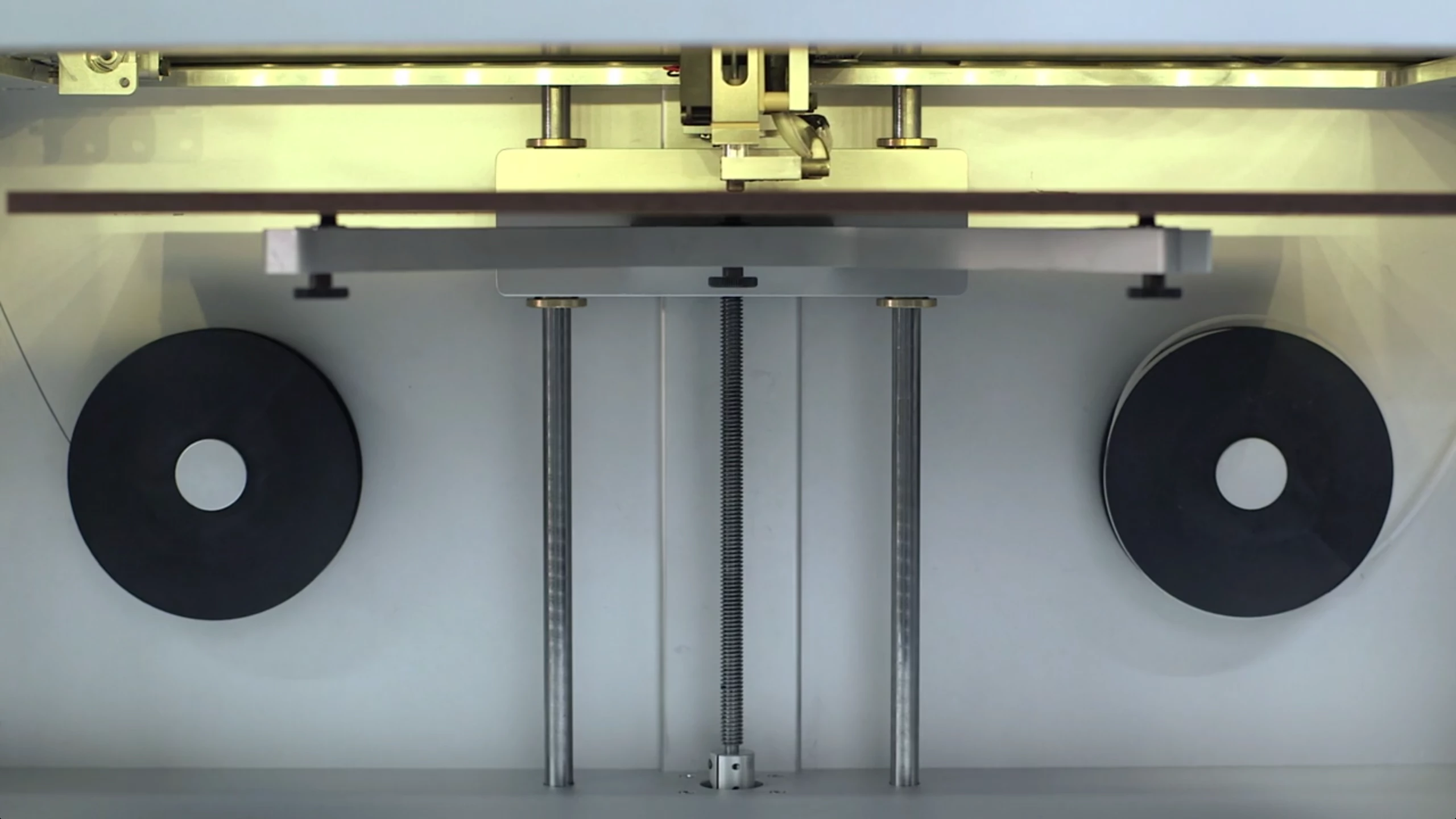

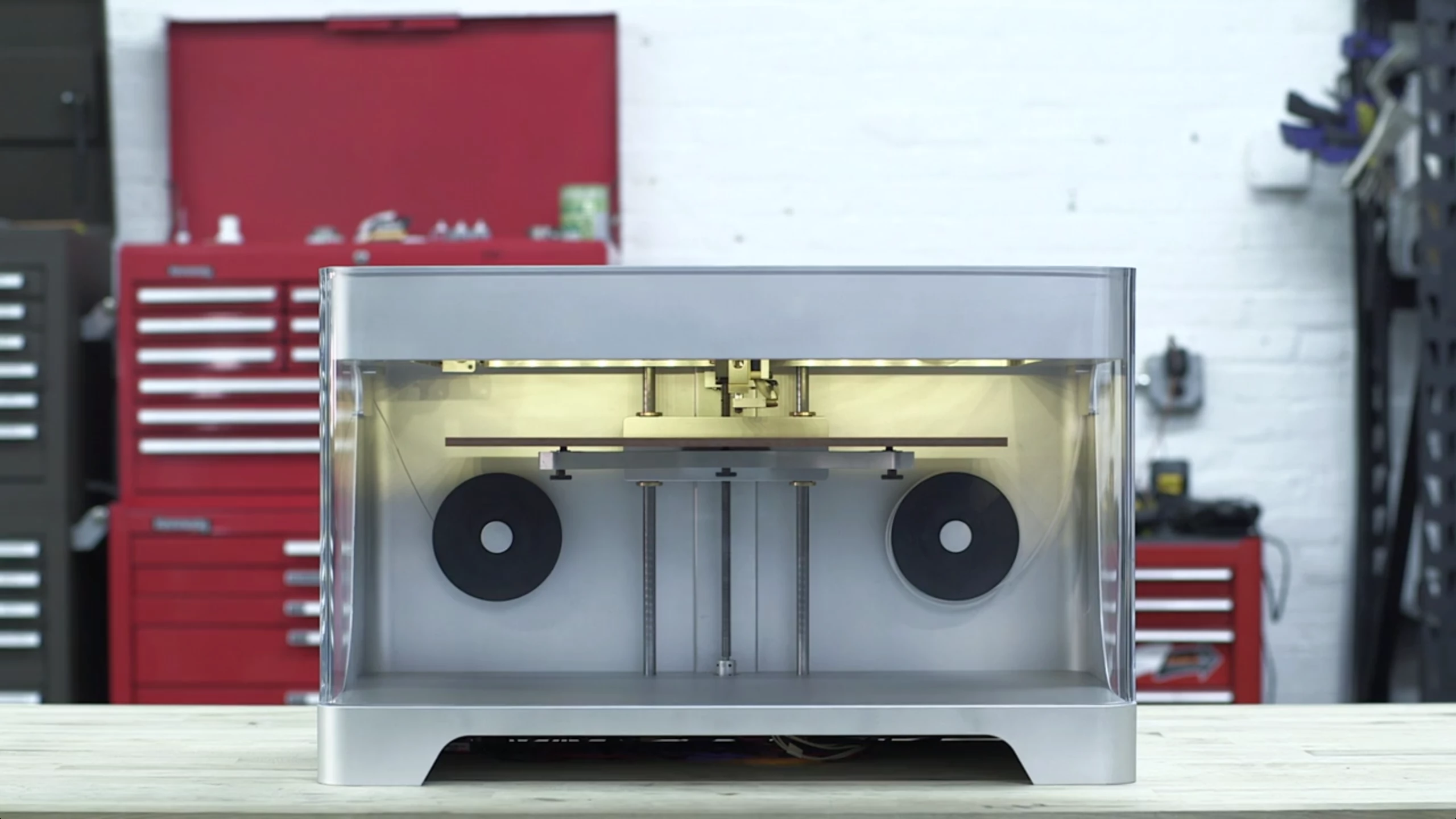

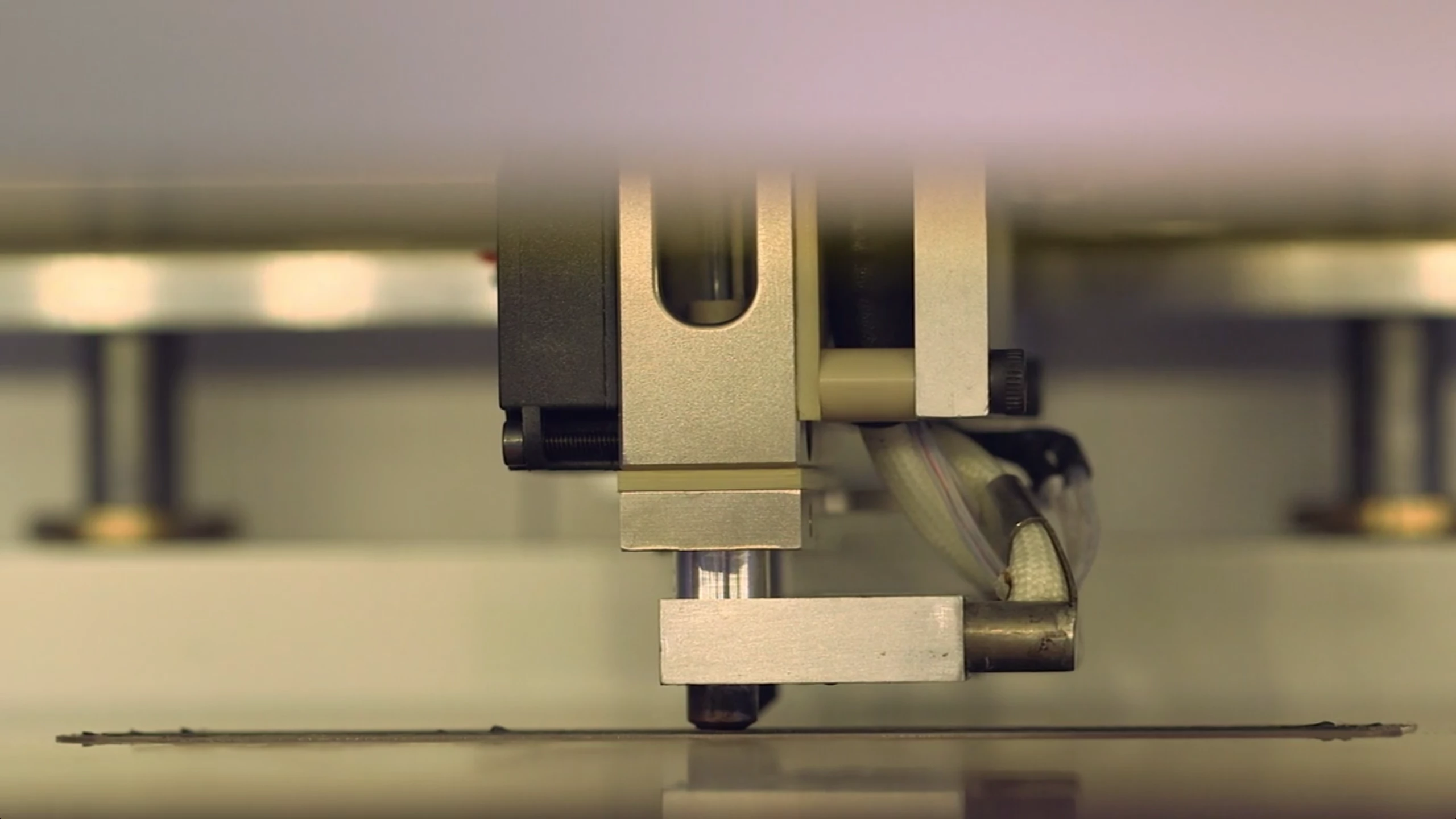

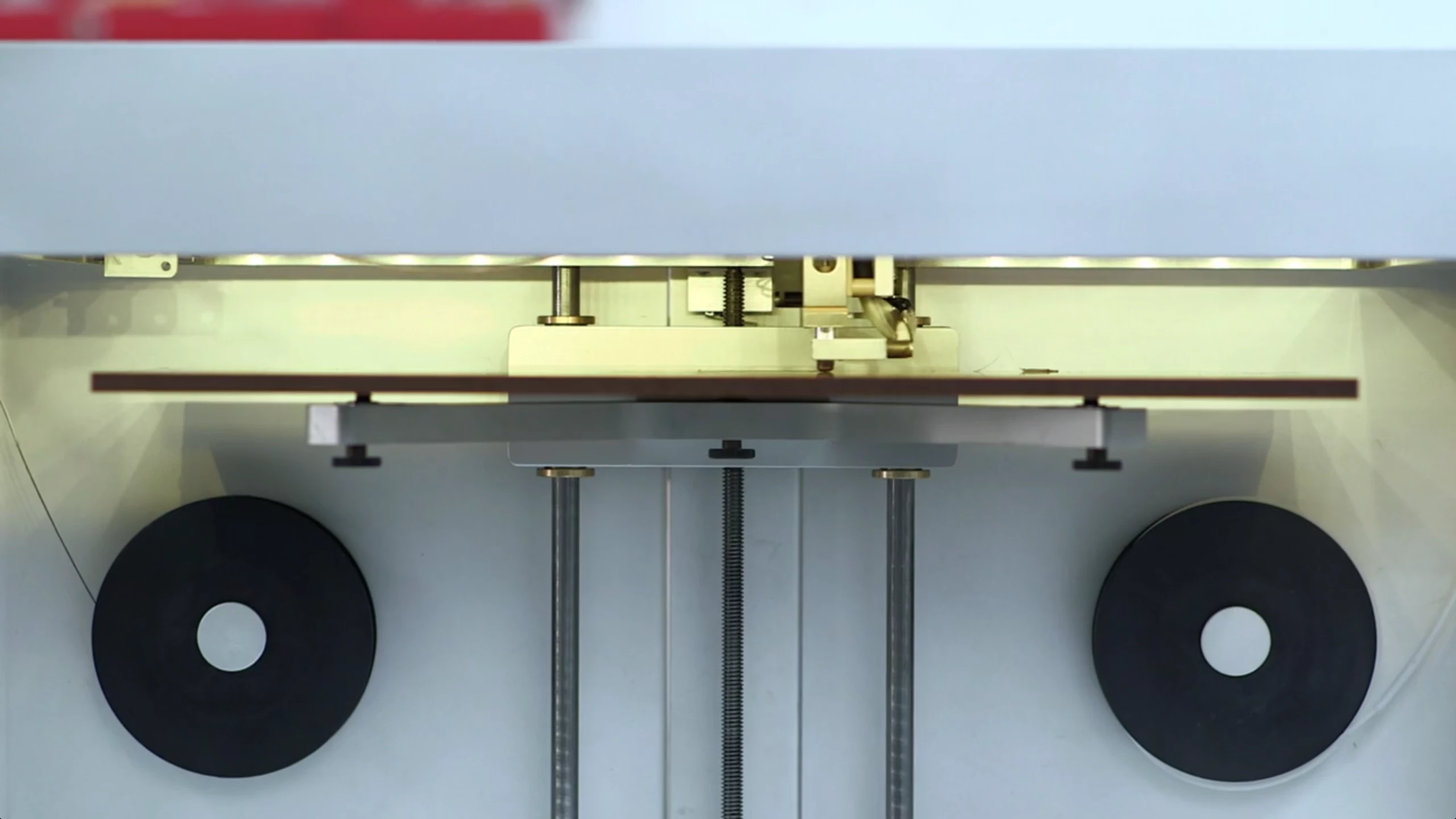

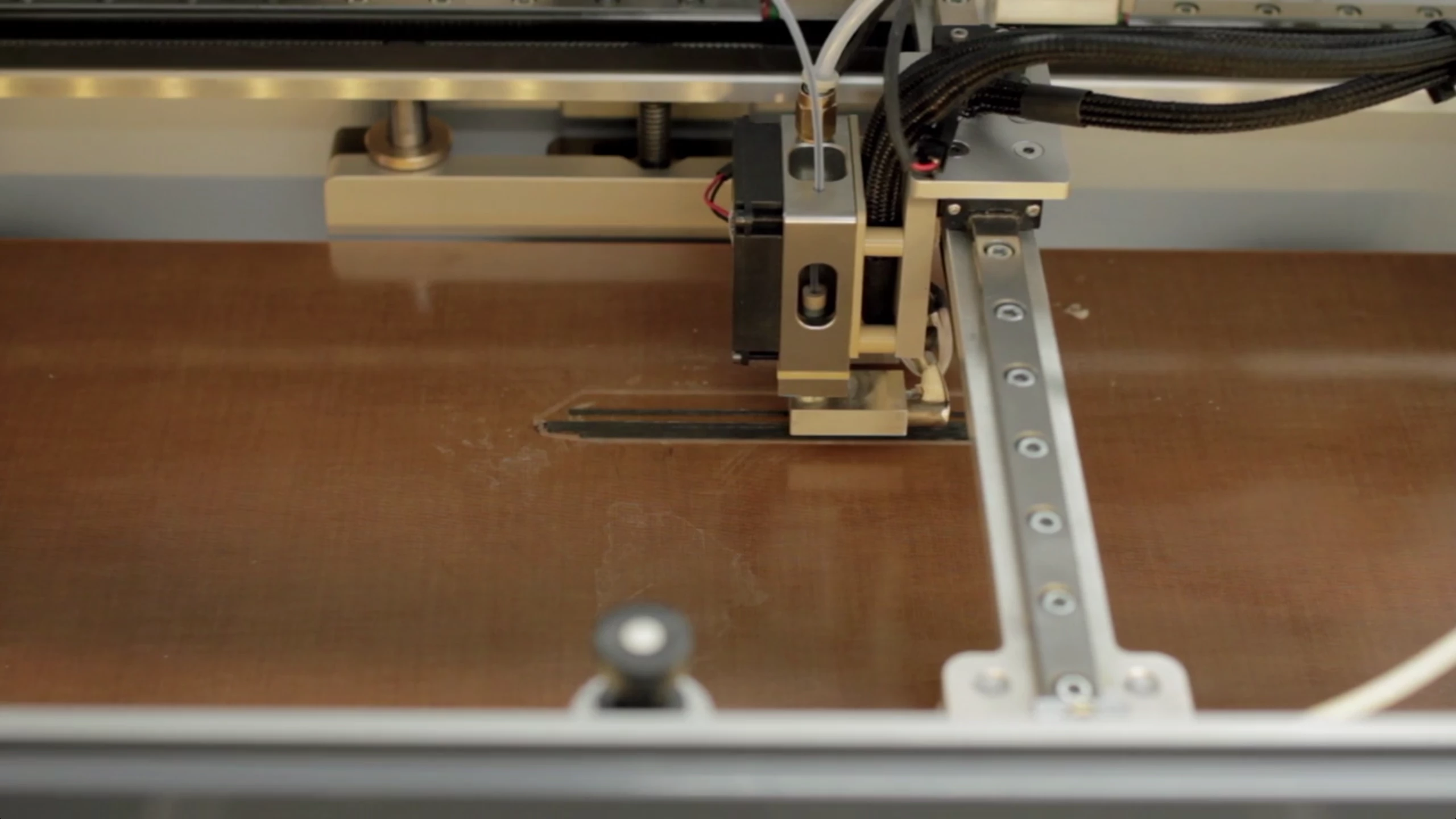

Designed and manufactured by MarkForged, the Mark One can print to a maximum size of 305 x 160 x 160 mm (12 x 6.25 x 6.25 in). In addition to CF, it can also print in fiberglass, nylon and polylactic acid (PLA) – although it only prints one material at a time through its dual extrusion print head. And since it's vital to be able to remove and replace the print tray in exactly the same place between layer runs, the Mark One's removable platform clips back in with 10-micron accuracy.

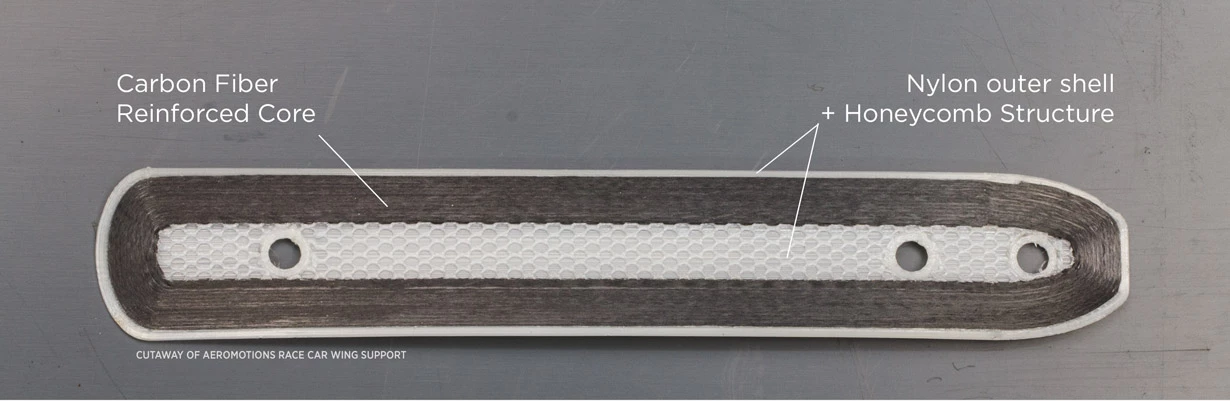

Automotive applications will be close to the heart of MarkForged President Gregory Mark, who also co-owns Aeromotions – a company that produces some really impressive computer controlled aerodynamic CF spoiler wings for high-performance race cars.

Of course, this kind of technology puts custom carbon parts within reach of all sorts of other industries as well, and allows intricate shapes to be formed that would be very tough to create using traditional CF manufacturing techniques.

At just $5,000, the Mark One will be well within the price range of many custom auto builders, and even possibly some backyard thumb-bangers with a flair for computer design. Exciting stuff! MarkForged says the Mark One will be "available soon."

The Mark One can be seen churning out some carbon fiber 3D prints in the following video.

Source: MarkForged via 3Dprint.com