Several feet below city streets around the world lurks a dangerous and unspeakably gross threat to our way of life: fatbergs.

These are giant concrete-like clusters of cooking oil, grease, nappies, wet wipes and such that congeal into masses in our sewers, clogging networks. They're not only hard to break up, but can also grow to immense proportions. In 2017, London saw a monstrous fatberg grow to a length of 820 ft (250 m) and reach 130 tons (118 tonnes) – about the same as two Airbus A318 planes.

Clearing these blockages before they cause sewage backups in our streets requires constant manpower and monitoring. In the US, it's estimated to cost the country as much as US$25 billion a year to break these up and fix the damage they cause.

A team of engineers at Australia's RMIT University are working on two ways to reduce these buildups – and they could save cities billions of dollars each year globally.

How do fatbergs form in the first place? Fat, oil, and grease (collectively known as FOG) mix with sewer water and calcium released from concrete sewer pipes, and solidify over time. FOG in particular comes from domestic and commercial kitchen wastewater, and while plumbing devices called grease traps intercept a large amount of FOG before it enters sewer lines, some of its still gets through.

Stopping grease in its tracks

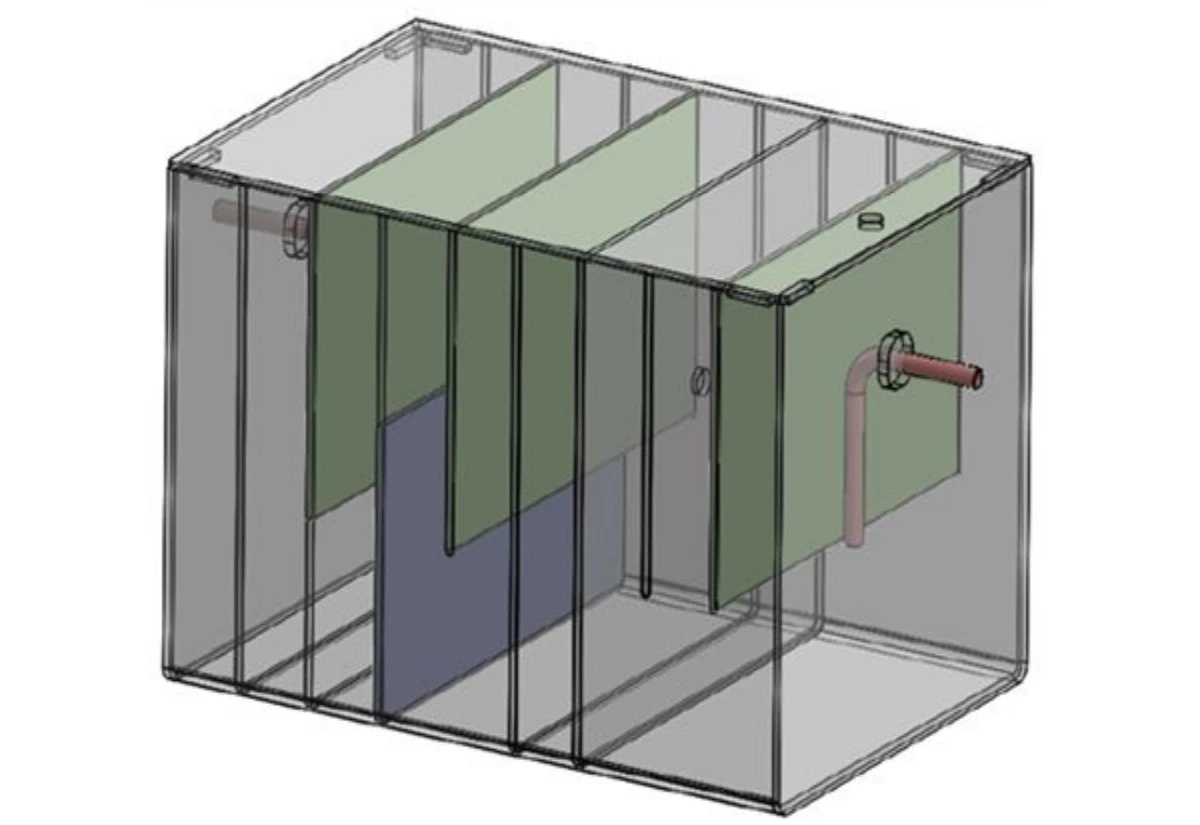

To further reduce FOG from entering sewer systems at the source, the RMIT team built a better grease trap that's more than twice as good at capturing fats than current systems. The researchers' design looks like a conventional grease trap on the outside, but actually features a a series of physical baffles which slow the flow of wastewater and separate larger fat particles. Next, alum – a water treatment chemical – is added to the contents to clump together smaller, suspended fats so they can be easily removed.

“While traditional interceptors only remove around 40% of fats, our system achieved up to 98% – even when tested with actual kitchen wastewater,” said Dr. Nilufa Sultana, lead author on the paper describing this system that appeared in the journal ACS ES&T Water in July.

She also noted that it worked effectively with high temperatures and when dish detergent flowed in along with the wastewater. What's more, this tech can be retrofitted to existing grease management systems for kitchens large and small.

The system isn't perfect yet, though: the researchers are working to incorporate fluid dynamics principles so they can enhance FOG removal without the need for chemical treatment – so it can be commercialized in line with public infrastructure regulations.

Better pipes = fewer fatbergs

For the second part of their one-two punch, engineers from the same research center developed a new coating for the interior walls of sewer pipes.

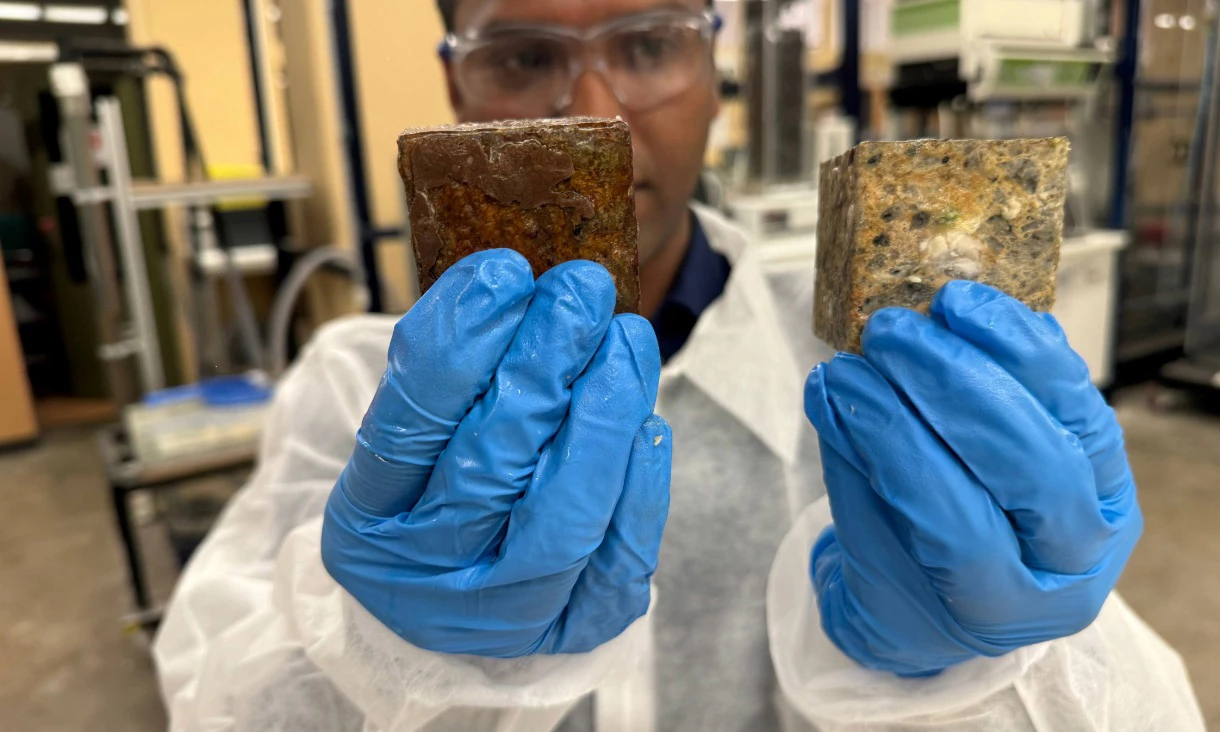

First, they mimicked the setting in which fatbergs form using concrete blocks (similar to sewer pipes) and synthetic FOG water under controlled conditions over the course of 30 days. That allowed the fatberg to form on regular concrete blocks, and on blocks with the new zinc-enhanced polyurethane coating they had concocted.

The coating reduced the release of calcium by 80%, and that in turn reduced the build-up of FOG on concrete by 30%. It's also self-healing, which means that if it's scratched or dinged up by hard materials flowing through sewer lines, the coating can repair itself and extend its lifespan.

That's a big win over the coatings that are commonly used at present. “Traditional coatings like magnesium hydroxide, widely used for over two decades, are effective in controlling sewer corrosion but can inadvertently contribute to FOG build-up by interacting with fatty acids,” explained Dr. Biplob Pramanik, who led the study into this novel coating that appeared in the Chemical Engineering Journal last November.

Dr. Pramanik's team is working to further improve the coating's mechanical strength so it can further reduce FOG deposition, and also improve its self-healing capabilities. He's additionally leading a project to create advance grease interceptors that will find use in restaurants, in collaboration with the Australian Research Council.