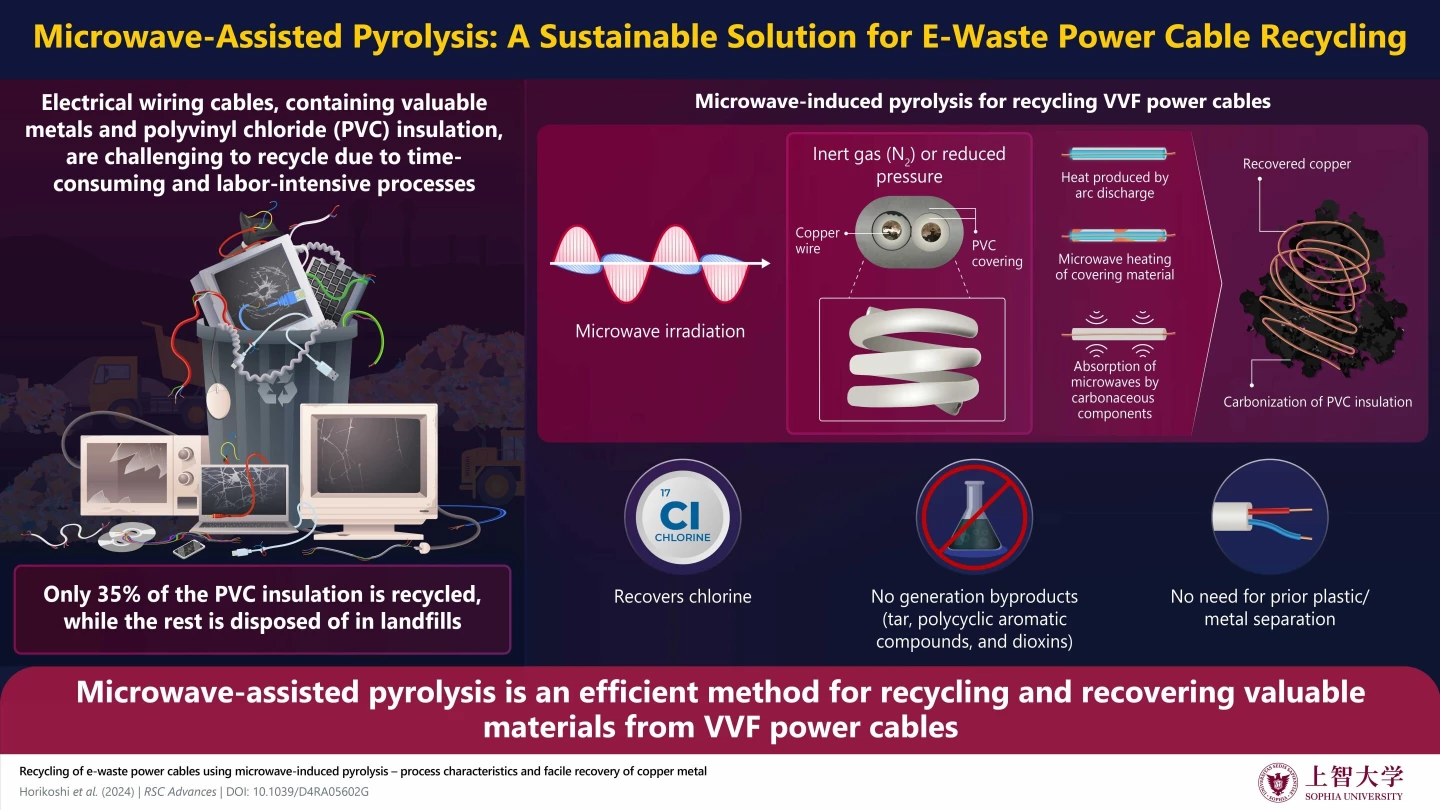

Italian and Japanese researchers have developed a novel method to free copper wire from its PVC coating, by treating electric cables with microwaves. The technique could go a long way towards helping tackle the growing problem of e-waste.

According to the ever-climbing ticker on the electronic waste (e-waste) monitoring site The World Counts, the amount of electronic waste disposed of in 2024 is over 50 million tonnes (or over 55 million tons). Of that, 76% comes from machines with power cords such as dishwashers, air conditioners, and electric shavers. The result is that there are a lot of power cords snaking their way through landfills across the world, where they both add to a growing problem of pollution and hide within them a valuable resource: copper.

Now, researchers from Sophia University in Japan and Università di Pavia in Italy have announced a new method that uses an inexpensive microwave process and the scientific principle of pyrolysis to deal with both issues.

Pyrolysis refers to using high temperatures to turn solids into a gas and a solid residue. This process typically takes place in an inert, or oxygen-free environment.

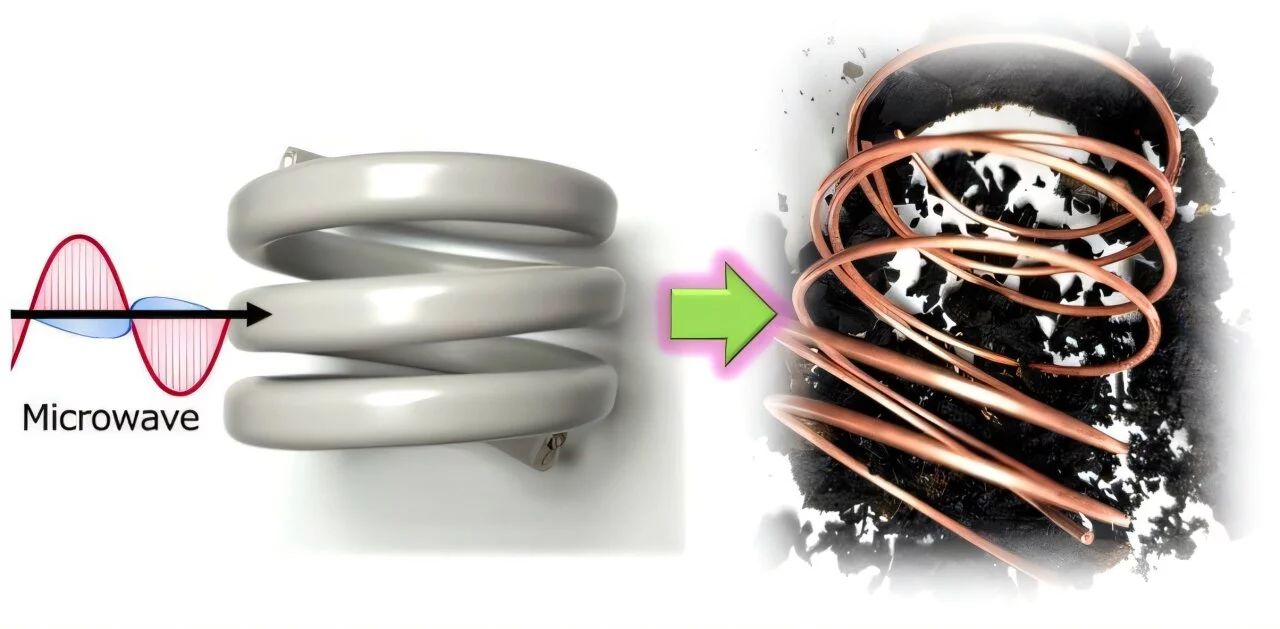

In their study, the researchers started with different lengths of VVF cables – the type of electrical wire often found in power cords – which consist of copper wires covered by a PVC sheath. By placing the cables in a glass reactor, exposing them to varying degrees of microwave radiation, and using nitrogen gas to prevent combustion, they were able to convert the PVC sheathing to chlorine gas and carbon. The copper was left behind to be harvested and reused.

According to study lead author Satoshi Horikoshi from Sophia University, the chlorine gas could be converted into useful hydrochloric acid, while the carbon and activated carbon formed from the PVC could be turned into carbon black, which is often used as a pigment.

The method worked despite the fact that PVC does not absorb microwave radiation. Instead, what happened is that the copper wire inside acted as a sort of antenna that absorbed the microwaves and in turn heated the surrounding PVC. As the PVC heated up and turned to carbon, it got better at absorbing the microwaves as well, which accelerated the entire process.

According to the researchers, only about 35% of PVC is recycled, so their method could dramatically boost that number, freeing up valuable and reusable copper in the process.

"VVF cables are commonly used as power cables in houses and buildings and have a high reuse value among e-waste," said Horikoshi. "Our method is suitable for recycling and recovering e-waste containing metals and requires no pre-treatment to separate the plastics from the metals."

Horikoshi's technique joins other methods of dealing with e-waste we've seen, including using whey from milk to recover gold from electronics; flash-heating ground-up circuit boards and then vaporizing them to recover other precious metals; and using a cryo-mill to freeze electronics to separate out potentially reusable resources.

The new study has been published in the journal, RSC Advances.

Source: Sophia University via Tech Xplore