Plastics are durable and strong, which is great while they’re being used but frustrating when they end up in the environment. Scientists at RIKEN in Japan have developed a new type of plastic that’s just as stable in everyday use but dissolves quickly in saltwater, leaving behind safe compounds.

The benefit of plastics is that they’re made with strong covalent bonds that hold their molecules together, meaning they take a lot of energy to break. This is why they’re so sturdy, long-lasting and perfect for everything from packaging to toys.

But those same strong bonds become a problem after the useful life of a plastic product is over. That cup you used once and threw away will sit in landfill for decades, even centuries, before it fully breaks down. And when it does, it forms microplastic pieces that are turning up in all corners of the natural world, including our own bodies, where they wreak havoc on our health in ways we’re only just beginning to understand.

RIKEN researchers have now developed a new type of plastic that can work just as well as the regular stuff when it’s needed, and break down readily into safe compounds when it’s not. It’s made of what are known as supramolecular polymers, which have reversible bonds that function like sticky notes that can be attached, removed and reattached, according to the team.

The team wanted to make a specific type of supramolecular polymer that would be strong enough for the usual uses of plastic, but could also be made to break down quickly when required, under mild conditions and leaving only non-toxic compounds.

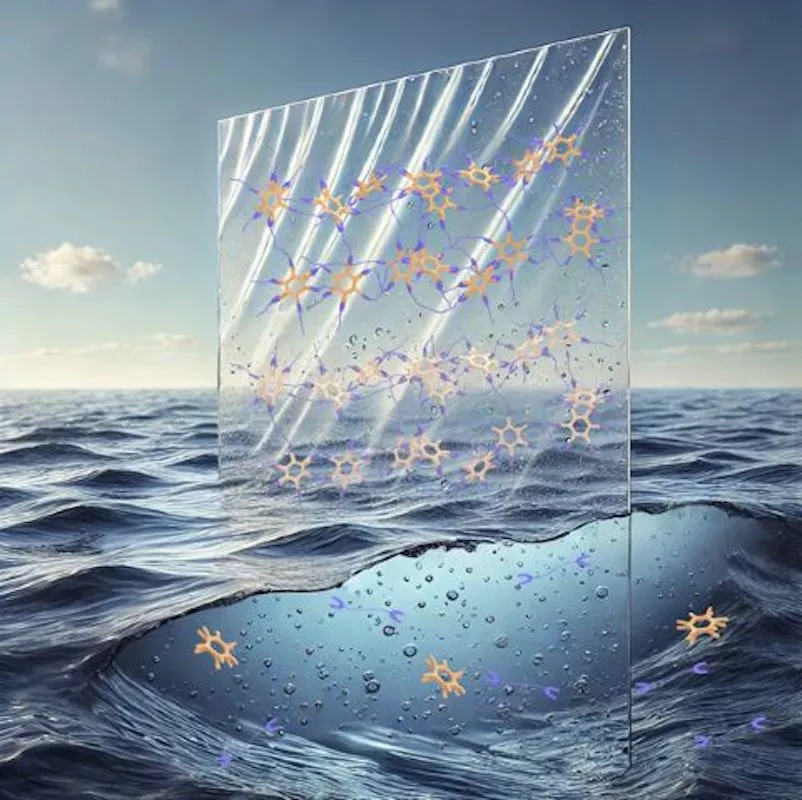

After screening a range of molecules, the researchers identified a particular combination that seemed to have the right properties – sodium hexametaphosphate, which is a common food additive, and monomers based on guanidinium ions, which are used in fertilizers. When these two compounds are mixed together in water, they form a viscous material that can be dried to form plastics.

A reaction between the two ingredients forms “salt bridges” between the molecules that make the material strong and flexible, like conventional plastic. However, when they’re soaked in saltwater, the electrolytes unlock those bonds, and the material dissolves.

In practice, the team found that the material was just as strong as normal plastic during use, and was non-flammable, colorless and transparent. Immersed in saltwater though, the plastic completely dissolved in about eight and a half hours.

There’s one major hurdle with any degradable plastic material of course: what if it comes into contact with the catalyst for its destruction before you want it to? A plastic cup is no good if certain liquids can dissolve it, after all.

In this case, the team found that applying hydrophobic coatings prevented any early breaking down of the material. When you eventually want to dispose of it, a simple scratch on the surface was enough to let the saltwater back in, allowing the material to dissolve just as quickly as the non-coated sheets.

While some biodegradable plastics can still leave behind harmful microplastics, this material breaks down into nitrogen and phosphorus, which are useful nutrients for plants and microbes. That said, too much of these can be disruptive to the environment as well, so the team suggests the best process might be to do the bulk of the recycling in specialized plants, where the resulting elements can be retrieved for future use.

But if some of it does end up in the ocean, it will be far less harmful, and possibly even beneficial, compared to current plastic waste.

A paper describing the research was published in the journal Science.

Source: RIKEN