One of the biggest difficulties in helping people affected by natural disasters is transporting and providing them with essential resources like safe drinking water. Researchers at Australia's RMIT University and five Chinese institutes have devised a simple and clever contraption that could solve that, by pulling potable water out of thin air.

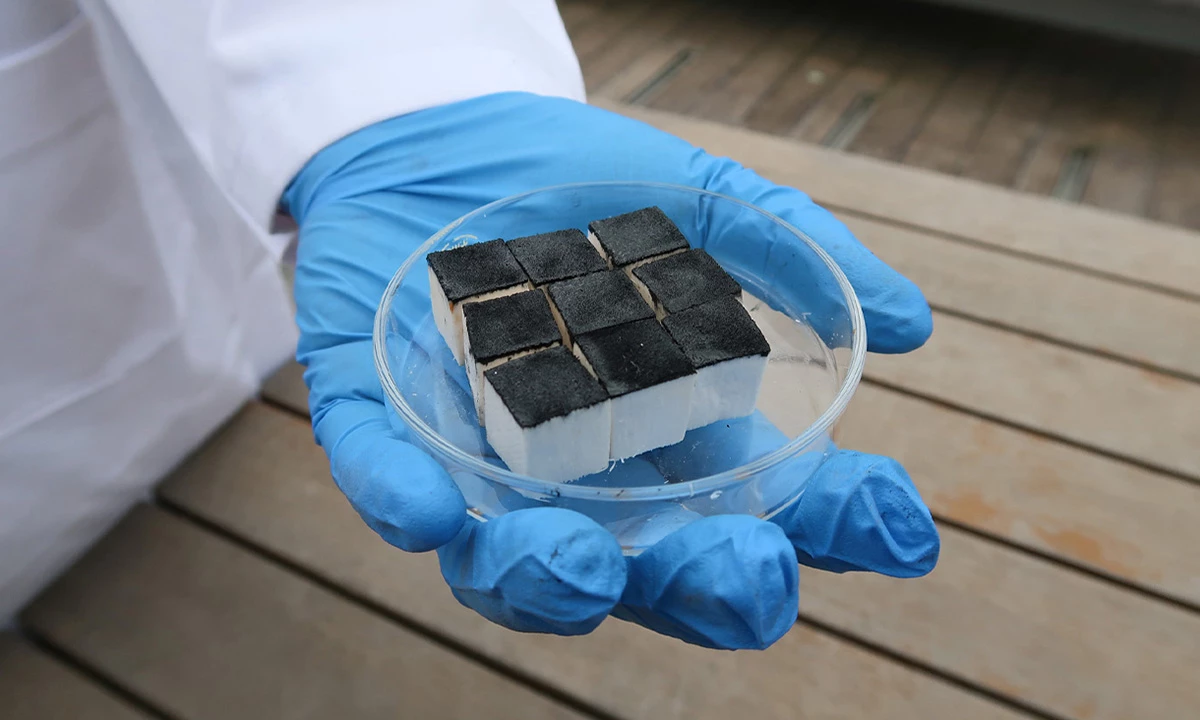

The team's invention uses a newly developed composite material based on porous, lightweight balsa wood shaped into small cubes; these are installed into a cup with a domed lid, a simple cooling mechanism, and an activation system powered by the Sun.

The spongy material, known as WLG-15, also contains lithium chloride to improve water absorption, and iron oxide nanoparticles that help the sponge's surface layer to absorb sunlight, and turn the absorbed water into vapor. The latter also helps the water release from the material.

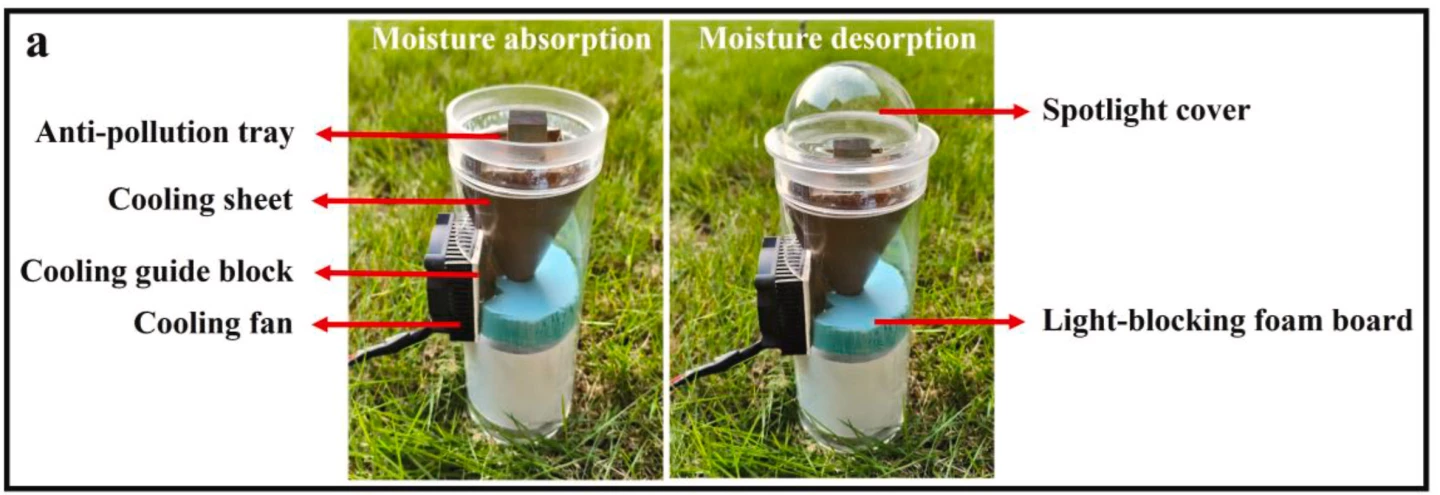

The device itself is pretty simple: when the cup's lid is open to the air, the WLG-15 material absorbs moisture from the atmosphere. When the lid is closed under sunlight, water is released into the cup. The domed lid initiates solar evaporation and facilitates the collection of the released water; a cooling plate, a heat sink block, and a cooling fan powered by a solar panel enhances condensation within the system.

The researchers noted that under lab conditions, their device absorbed about 0.03 fl oz (2 ml) of water per gram of WLG-15 material at 90% relative humidity, and released nearly all the water within 10 hours under the Sun. That doesn't seem like much, but when you consider that the blocks are awfully small and lightweight, it could prove to be effective in a larger configuration, or in an array of collection devices.

For reference, a set of nine little sponge cubes shown below – each of which weigh less than a gram – can release 0.5 fl oz (15 ml) into the cup. The researchers published the results of their work in the Journal of Cleaner Production in March.

According to the team, this level of efficiency is higher than most other known methods like fog harvesting and radiative cooling, and cheaper thanks to the use of widely available and inexpensive balsa wood. In a bigger setup, it could potentially find use as a portable water harvesting system for emergency aid in disaster-stricken areas, with solar energy powering the cooling system.

Dr. Junfeng Hou from Zhejiang A&F University, who led the Chinese institutes' collaboration with RMIT, noted that WLG-15 also worked just fine after being stored at sub-zero temperatures for weeks, and could be reused multiple times without much of a decline in efficiency. As such, the material could even be "deployed in real-world applications such as water collection in remote or arid regions.”

If you've been reading New Atlas for a bit, you've probably come across commercially available atmospheric water generators (AWG) – electronic appliances that promise to do the same thing, with far greater speed and volumes. Why not just deploy those to disaster-stricken locations and far-flung areas where water is hard to come by?

They seem like an ideal solution for water-scarce regions, but the main reason is AWGs use substantial amounts of electricity to condense water vapor from air. Many water-stressed regions have unreliable or no electrical grid access, so you'd likely have trouble powering these machines. Solar-powered options exist, but add significant cost and complexity to the equation.

Plus, AWGs work best in environments with above-60% humidity; that may not be the case in many of the locations you're thinking of. And finally, these systems can be expensive, both to purchase upfront and to maintain with specialized technical expertise and custom parts. So while they might indeed do what it says on the tin, AWGs aren't necessarily an easily applicable solution for water scarcity.

Back to WLG-15: the researchers used AI to predict the air-to-water device's performance under a range of environmental conditions. Similar tech could also help them uncover more combinations of materials for efficient water capturing composites. The team is currently exploring ways to pilot production of this material with industry partners and test it in the field.

Oh, and incidentally, RMIT University has come up with another sponge-inspired innovation recently: a super strong-material inspired by sea sponges that could find use in constructing more durable buildings.

Source: RMIT University