A light weight and slim form are two very desirable attributes when it comes to next-gen armor materials, and we're seeing scientists make impressive gains in this area, inspired by everything from sea snails, to animal scales, to finely tuned foams. The latest example comes from material scientists at MIT, who have used advanced nanoscale engineering to craft a new armor material they say outperforms Kevlar and steel.

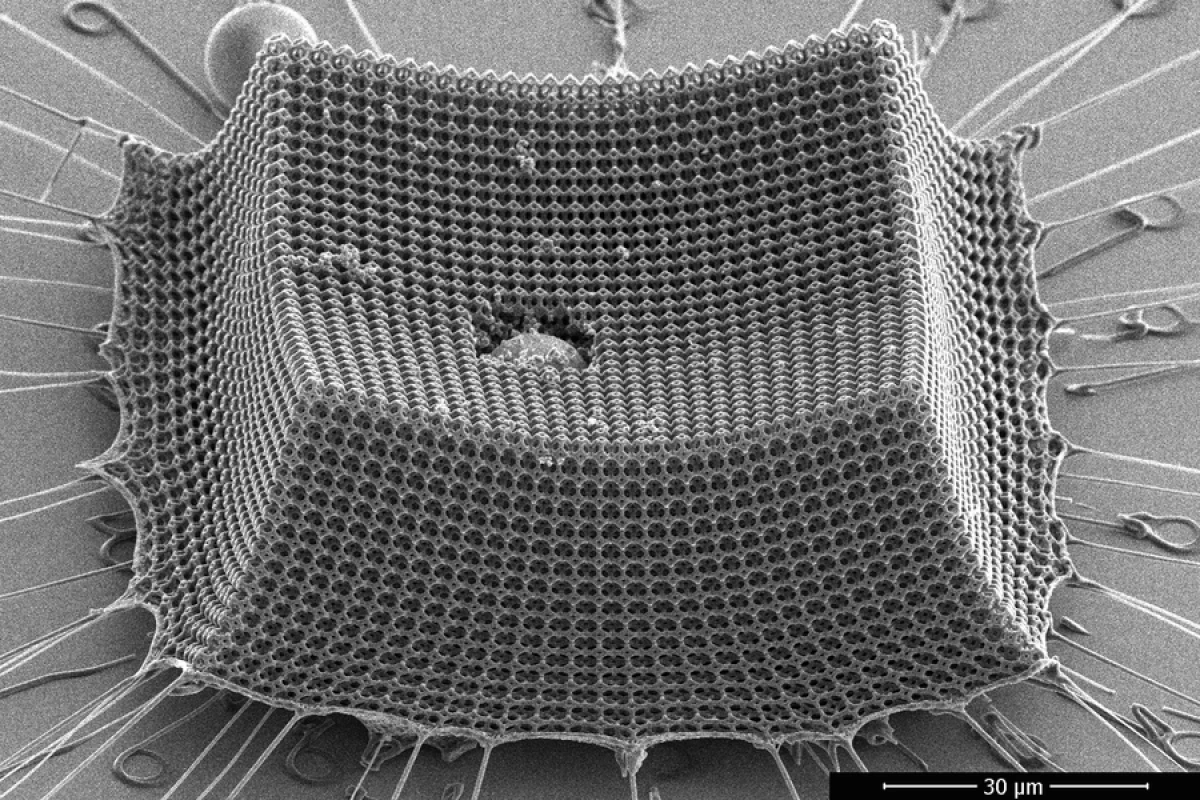

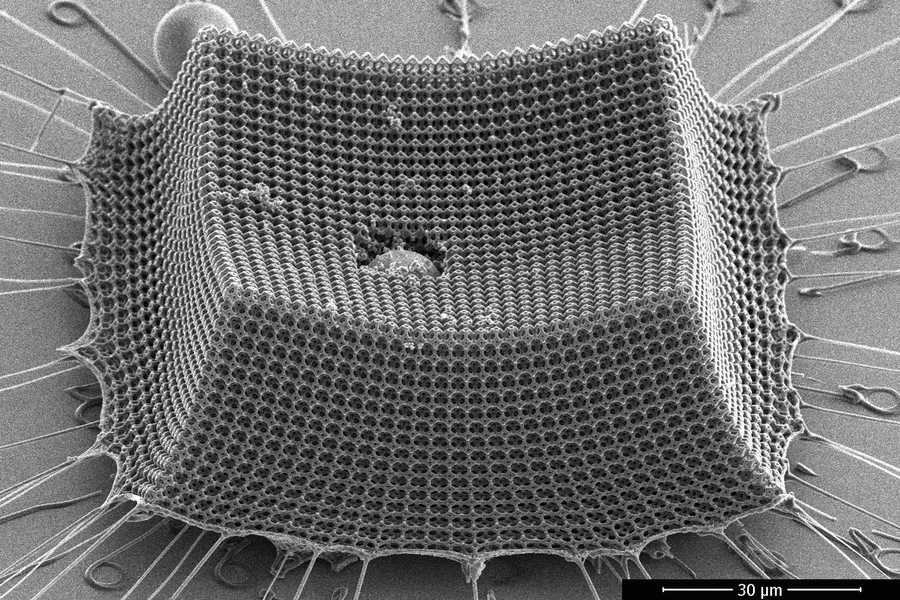

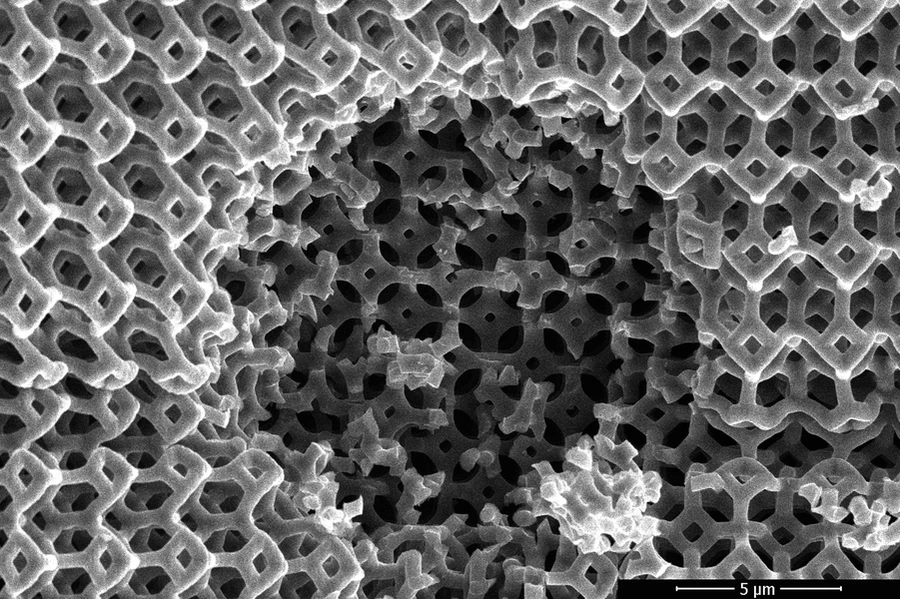

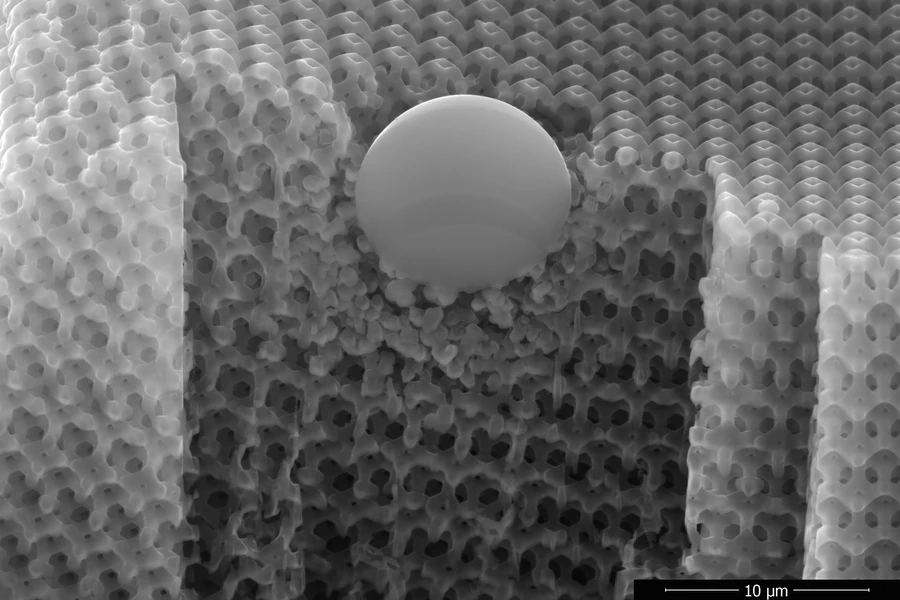

The starting point for the promising new material was a photosensitive resin, which was treated with lasers to form a lattice pattern made up of repeating microscopic struts. This material was then put in a high-temperature vacuum chamber, which converted the polymer into an ultralight carbon with an architecture originally inspired by special foams designed to absorb impacts.

“Historically this geometry appears in energy-mitigating foams,” says lead author, Carlos Portela. “While carbon is normally brittle, the arrangement and small sizes of the struts in the nanoarchitected material gives rise to a rubbery, bending-dominated architecture.”

The team found the properties of this lattice material could be altered by tweaking its finely tuned architecture, with different arrangements of the carbon struts giving it different properties. This is a common characteristic of materials made up of nanoscale structures, but the team used an interesting approach to study these effects under real-world conditions.

“We only know about their response in a slow-deformation regime, whereas a lot of their practical use is hypothesized to be in real-world applications where nothing deforms slowly,” says Portela.

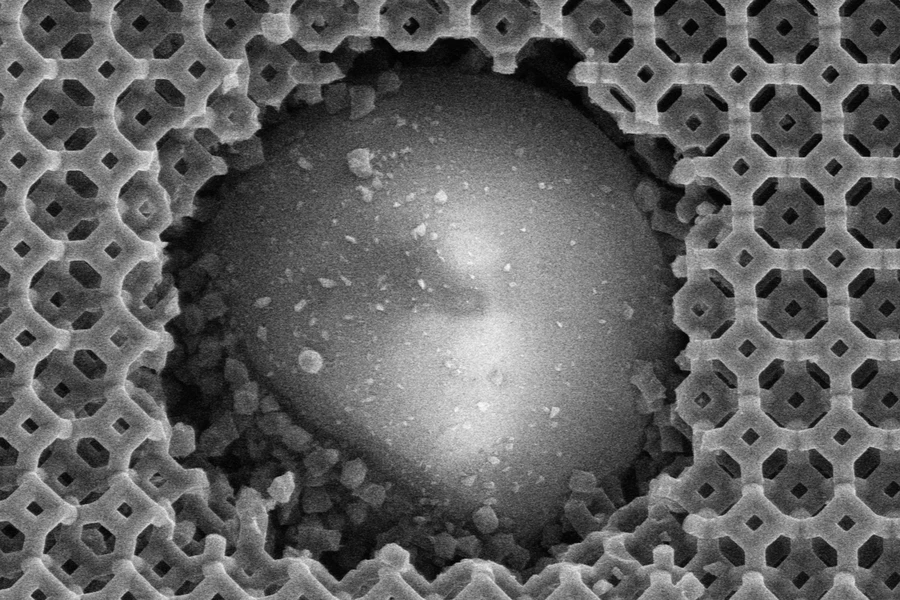

The impact experiments involved a glass slide coated with a gold film and silicon oxide particles on one side. An ultrafast laser is then beamed at the slide and generates a plasma, or rapidly expanding gas, which sends the particles flying off the surface towards the target. Adjusting the power of the laser in turn adjusts the speed of the projectiles, allowing the scientists to experiment with a range of velocities in studying the potential of their new armor material.

This included firing particles at speeds ranging from 40 to 1,100 meters per second (89 to 2,460 mph), which is deep into supersonic velocity territory, with high-speed cameras used to capture the impact events for study. The approach also enabled testing of different designs with carbon struts of differing thicknesses, and allowed the team to land on the optimal design through which particles embedded in the material, rather than tore right through it.

"We show the material can absorb a lot of energy because of this shock compaction mechanism of struts at the nanoscale, versus something that’s fully dense and monolithic, not nanoarchitected,” Portela says.

According to the team's analysis of the material, which is thinner than the width of a human hair, it could absorb impacts more efficiently than steel, aluminum or even Kevlar of a comparable weight. Scaling up the approach could therefore see it serve as the basis for alternative armor that is lighter and tougher than traditional materials.

“The knowledge from this work … could provide design principles for ultra-lightweight impact resistant materials [for use in] efficient armor materials, protective coatings, and blast-resistant shields desirable in defense and space applications,” says co-author Julia R. Greer.

The research was published in the journal Nature Materials.

Source: MIT