Whether they're caused by injury, disease or other factors, missing sections of bone can be quite difficult to replace. A new injectable hydrogel could change that, however, by transforming into a robust bone regeneration material when exposed to visible light.

While bone injuries such as fractures typically heal on their own, large sections of missing bone (known as "bone deficits") often never grow back.

As a result, they typically have to be filled with a piece of bone tissue harvested from one of the patient's leg bones. Not only is this an invasive and painful procedure, it also simply shifts the bone deficit from one part of the skeleton to another.

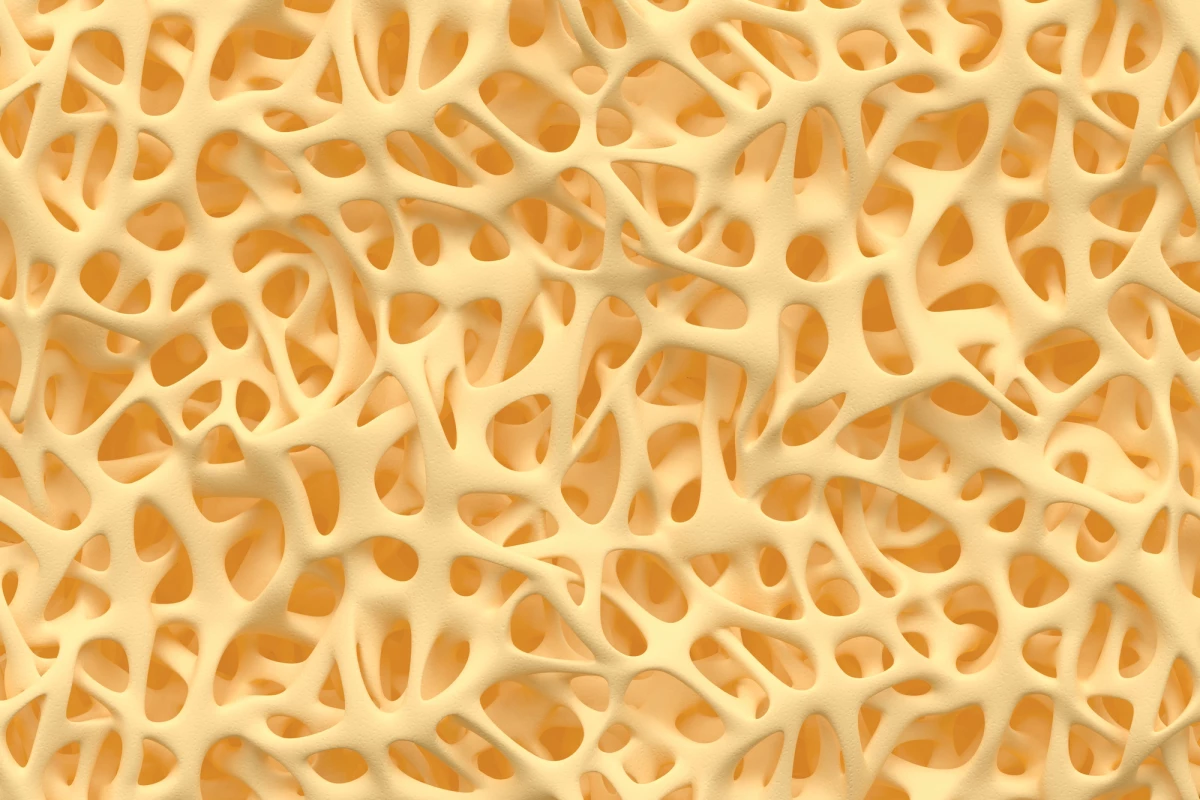

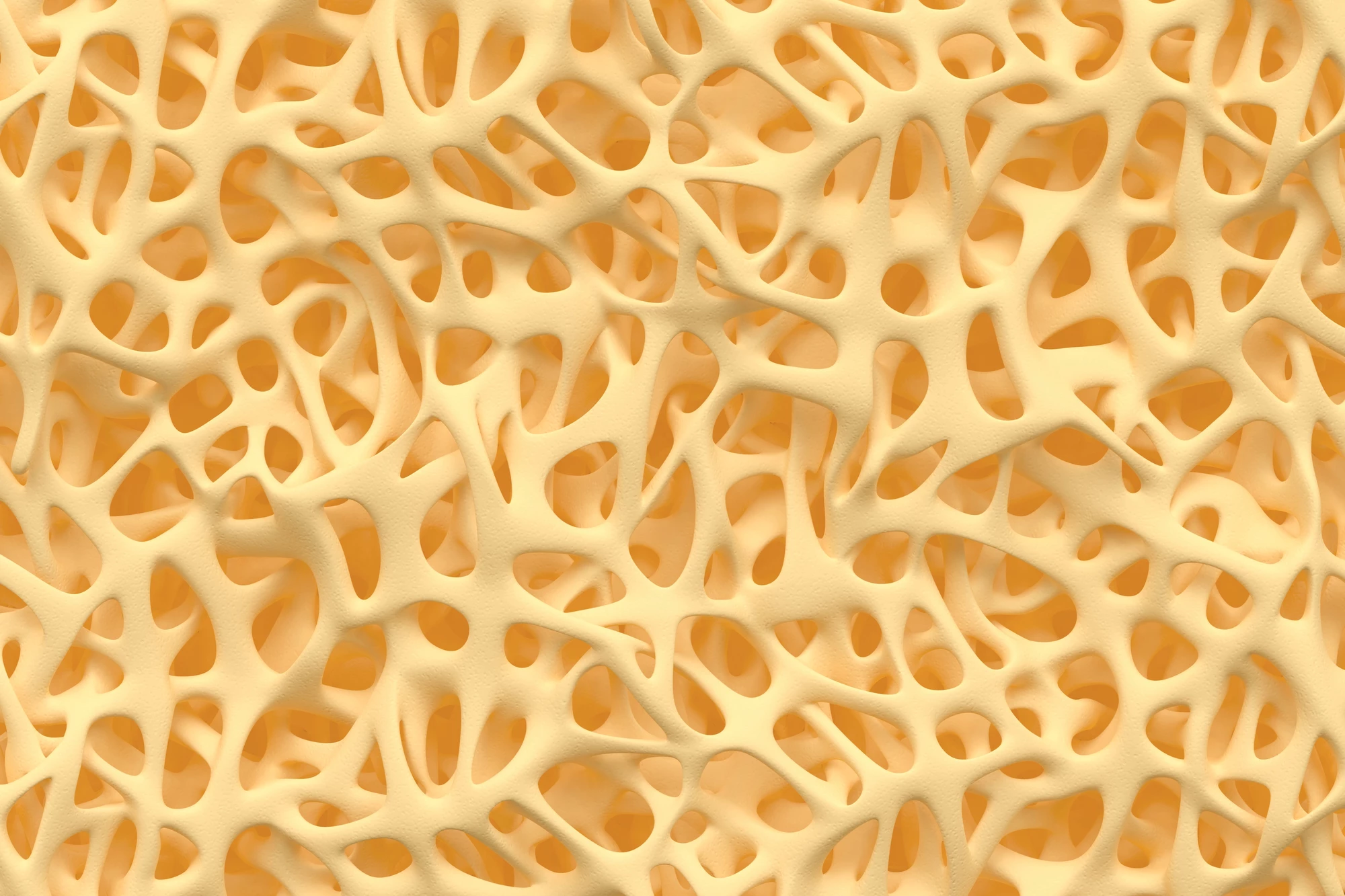

Seeking a more effective alternative, some groups are developing bone-like porous materials that are placed in the deficit instead of real bone.

Cells from the adjacent bone tissue gradually migrate into such a material, where they proceed to reproduce as the material harmlessly biodegrades. Eventually, the implanted material ends up being completely replaced by new, natural bone.

Some of these experimental bone regeneration materials are initially 3D-printed outside of the body, then secured into the deficit using an adhesive. Unfortunately, such adhesives sometimes fail.

Another approach involves injecting the material directly into the deficit, in the form of a gel that subsequently hardens into a solid. While this may sound like a better technique, some of these substances take a long time to set, they aren't sufficiently biodegradable, and/or they lack mechanical strength.

That's where the new material comes in.

Created by Prof. Hyung Joon Cha and colleagues at Korea's Pohang University of Science and Technology (POSTECH), it's a hydrogel made up of alginate (derived from algae), a bioengineered mussel adhesive protein, calcium ions, a chemical known as phosphonodiol, and a photoreactive agent.

When the gel is injected into a bone deficit then irradiated with harmless visible light, its polymer chains crosslink with one another, causing it to become a strong, porous, biodegradable solid that securely bonds with the adjacent bone tissue.

At the same time that this is happening, amorphous calcium phosphate forms within the material. This very bone-like compound serves as a "roost" for the adjacent bone cells, boosting the rate at which they move in, reproduce, and replace the material with real bone.

The hydrogel has been successfully tested on rats with femoral bone deficits. There is currently no word on when human trials may commence.

"The injectable hydrogel system for bone regeneration developed by our research team represents an innovative alternative to conventional complex treatments for bone diseases and will greatly advance bone tissue regeneration technology," says Cha.

A paper on the study was recently published in the journal Biomaterials.

Source: POSTECH