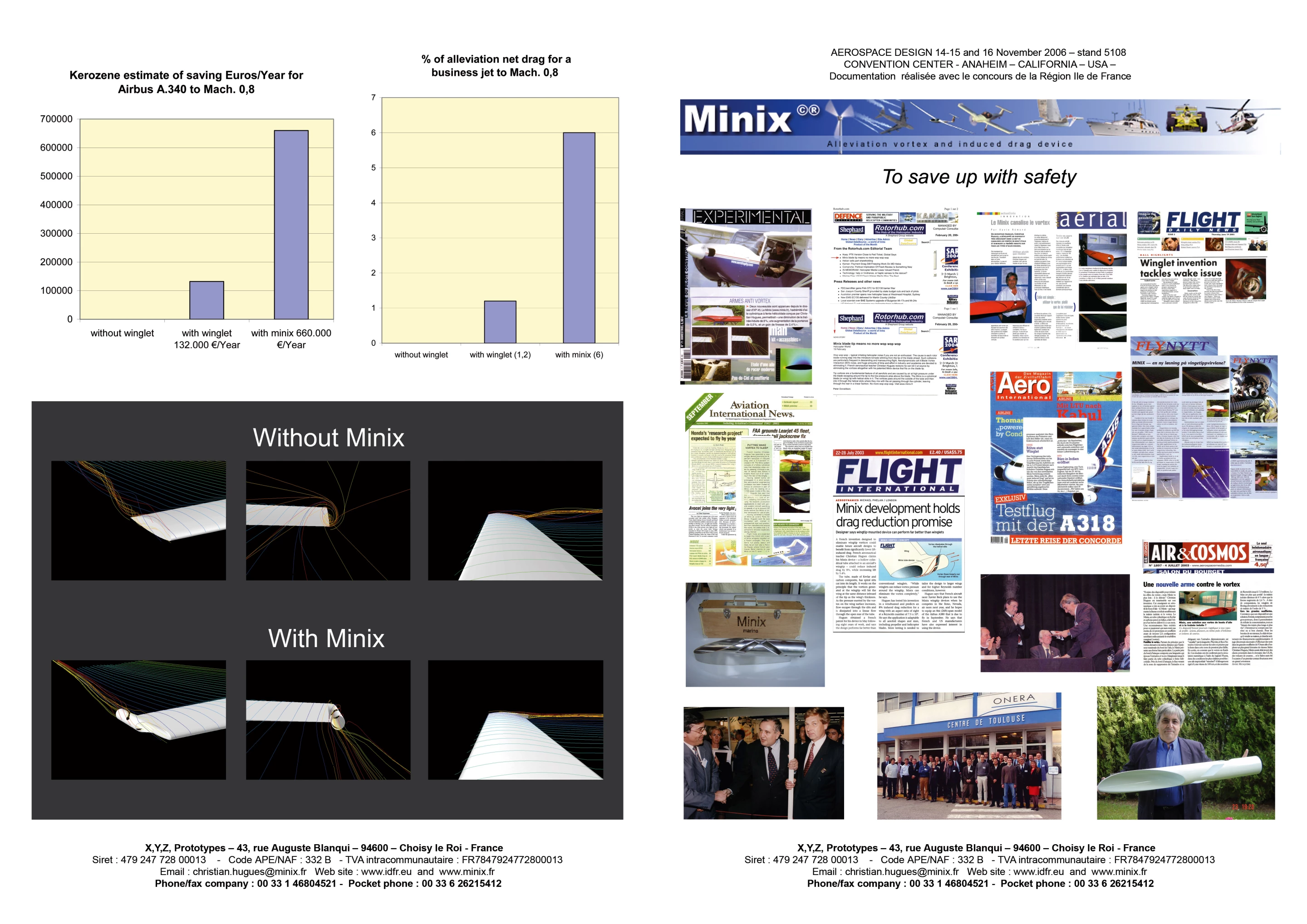

Fuel consumption and greenhouse gas emissions are huge priorities in the aviation industry – passenger airliners chew through amazing quantities of fuel. Take the Boeing 747, which guzzles somewhere around a gallon of jet fuel per second – it's clear that a percentile improvement in fuel consumption can make a huge difference to costs at the end of a long-haul flight. That's why the Minix wing tip deserves close scrutiny. It replaces the tilted winglets at the tip of an aircraft wing, can be retrofitted to any airplane, and smooths out the wing-tip vortex, reducing the aircraft's wing drag. Minix claims the design is five times more effective than a regular winglet and can save as much as 6% on an aircraft's energy costs. For a commercial Boeing 747, that equates to a saving of around 600,000 gallons of fuel per year, per aircraft. Food for thought.

Air travel gets a fair bit of bad press in terms of fuel efficiency and emissions, but in truth, provided you're traveling in excess of 500km, in a plane full of other passengers, the numbers would put it about level with driving that distance solo in an average car.

That's not to say that global air travel doesn't make a significant contribution to emissions, or that it's a super fuel-efficient way to travel - just that it's not as bad on these two axes as many people think.

Still, jumbo jets and other large aircraft do go through a staggering amount of fuel per journey, so an opportunity for a tiny efficiency gain is an opportunity to save significant money, as well as helping lower emissions.

French aeronautics teacher Christian Hugues believes he's come up with an aerodynamics breakthrough that could increase an aircraft's fuel economy by a massive 6% – and Gizmag checked it out earlier this week at the Paris Green Air Show.

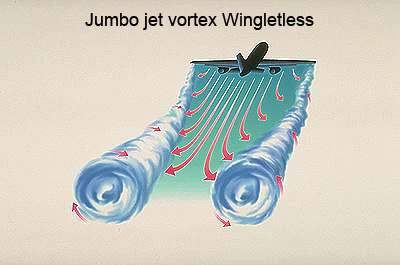

The Minix device sits at the tip of an aircraft's wing as a replacement to the vertical or tilted winglets now common on many craft. Its primary purpose is to smooth out and negate the high-pressure spiral vortices that form when a plane is in motion as the high-speed airflow struggles to deal with the complex pressure differences in the area where the wing terminates.

These vortices not only create a significant amount of drag on the aircraft, they create a turbulent and occasionally dangerous pressure wake that can interfere with other planes that pass through the same airspace. Planes have crashed after taking off too close behind other aircraft and being unable to deal with this vortex effect.

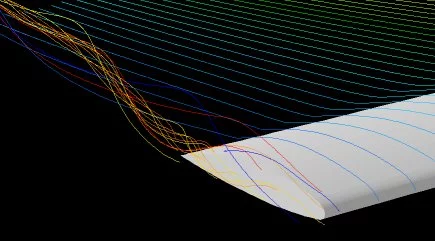

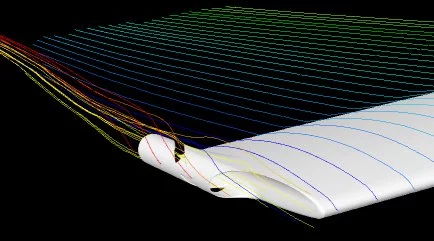

The Minix wing tip can be retrofitted to any aircraft wing. Its cylindrical shape prevents the airstream from trying to 'curl' around the edge of the wing, which is how the wing-tip vortex is created. The simulation diagrams below show how much smoother the airflow comes off the wingtip with a Minix cylinder fitted - and the developer claims that prototype testing has shown a 6% gain in drag efficiency at Mach 0.8 - the typical speed of an airliner.

Above: regular wing tip showing turbulent vortex

Above: Minix wing tip showing smooth airflow with no vortex

On top of the reduced vortex effect and overall aerodynamic drag, the Minix system produces increased lift at the wing tip, which is especially useful during landing. And Hugues claims it should also be cheaper to produce than a traditional winglet.

The Minix system can also be fitted to wind turbine blades for a similar gain in performance as wing-tip drag is eliminated. Hugues claims an extraordinary 14% greater annual electrical output from a minix-fitted turbine.

Pie in the sky? It's hard to tell. But the claimed figures make a very compelling argument for further testing. We'll keep our eye on this one!