Prepare to start seeing unprecedented shapes and designs in the motocross world. Spanish company Stark Future is taking titanium 3D printing out of the prototyping lab, and into mass production of its insane electric dirtbikes.

This represents a world-first in the automotive industry, according to the company, and a significant moment in manufacturing history.

By now, everyone's aware of the incredible capabilities that 3D printing opens up – such as virtually waste-free production of lightweight titanium parts in shapes that would be impossible to achieve with CNC milling, casting or forging – not to mention the ability to tailor each unit to a customer's specific requirements.

Titanium 3D printing is already well-established as a key production method in sectors like aerospace – where it can significantly bring down the crucial weight of structural aircraft components – and medicine, where custom-tailored titanium implants can be created to perfectly integrate with a patient's own physiology, while encouraging bone regrowth.

In automotive, though, where weight typically isn't as crucial and volume is king, it's been viewed as too slow, too expensive and too fiddly, so it's mainly been used for rapid prototyping and concept work – and the odd ultra-exclusive hypercar.

There's no better example of the latter than the extraordinary Czinger 21C, which uses more than 350 3D-printed components to keep its entire chassis weight down to just 120 kg (265 lb). Using 3D metal printing allows Czinger to take full advantage of generative (or evolutionary) design, resulting in strong, lightweight, skeletal, organic-looking part designs – and a car that simply couldn't be built any other way.

But Czinger only ever promised to build 80 hypercars. Stark Future, on the other hand, makes the hottest electric dirtbike on the market, and while production might not yet be at Honda levels, the company claimed in June that it was making 1,000 bikes per month, and is on track to become the fastest-growing startup in Spain.

The Stark Varg is an absolute weapon of a dirt-squirter – a battery-electric dirtbike that weighs little more than a fully-fueled 450cc race bike, while going just as far between top-ups and absolutely demolishing the ICE bikes on power (80 hp / 60 kW) and torque (692 lb-ft / 938 Nm at the rear wheel). This thing is a serious contender.

It does struggle to offset the weight of its battery, though, and as a result comes in at an unfortunate 260 lb kg (118 kg), which makes it a little harder to throw around than, say, the "race ready" 240-lb (108-kg) KTM 450 SX-F.

This may cease to be an issue with the next model. Stark Future has signed onto a strategic partnership with German company Farsoon Technologies, to bring large-format titanium printing into its production line.

Farsoon will supply Stark with its 8-ton FS721M CAMS machine, capable of continuously printing parts up to 72 x 42 x 65 cm (28 x 17 x 26 inches) in size, using no less than eight 500- or 1,000-W lasers to print some 500 cc (30.5 cubic inches) of material per hour.

"Farsoon’s cutting-edge large-format metal 3D printing technology empowers us to scale production of a technology previously only used in F1, space and prototyping," says Stark CEO Anton Wass, in a press release, "while maintaining our rigorous standards for performance and durability. Together, we are raising the bar in the motorcycle industry and are confident that this partnership will drive innovations that have never been done before in production vehicles. Stark expects to be the first automotive manufacturer to mass-produce components in titanium 3D printing."

And that's the fun part: that wild Varg above doesn't currently use any titanium parts. This new partnership appears to be focused on a future Stark model that could take what Czinger has done in the hypercar world and roll it out in a mass-market motorcycle product at scale.

We have no doubt this will result in one of the craziest-looking production motorcycles ever to ship – and we're fascinated to learn just how much weight can be saved, and where the companies will use the technique throughout the bike.

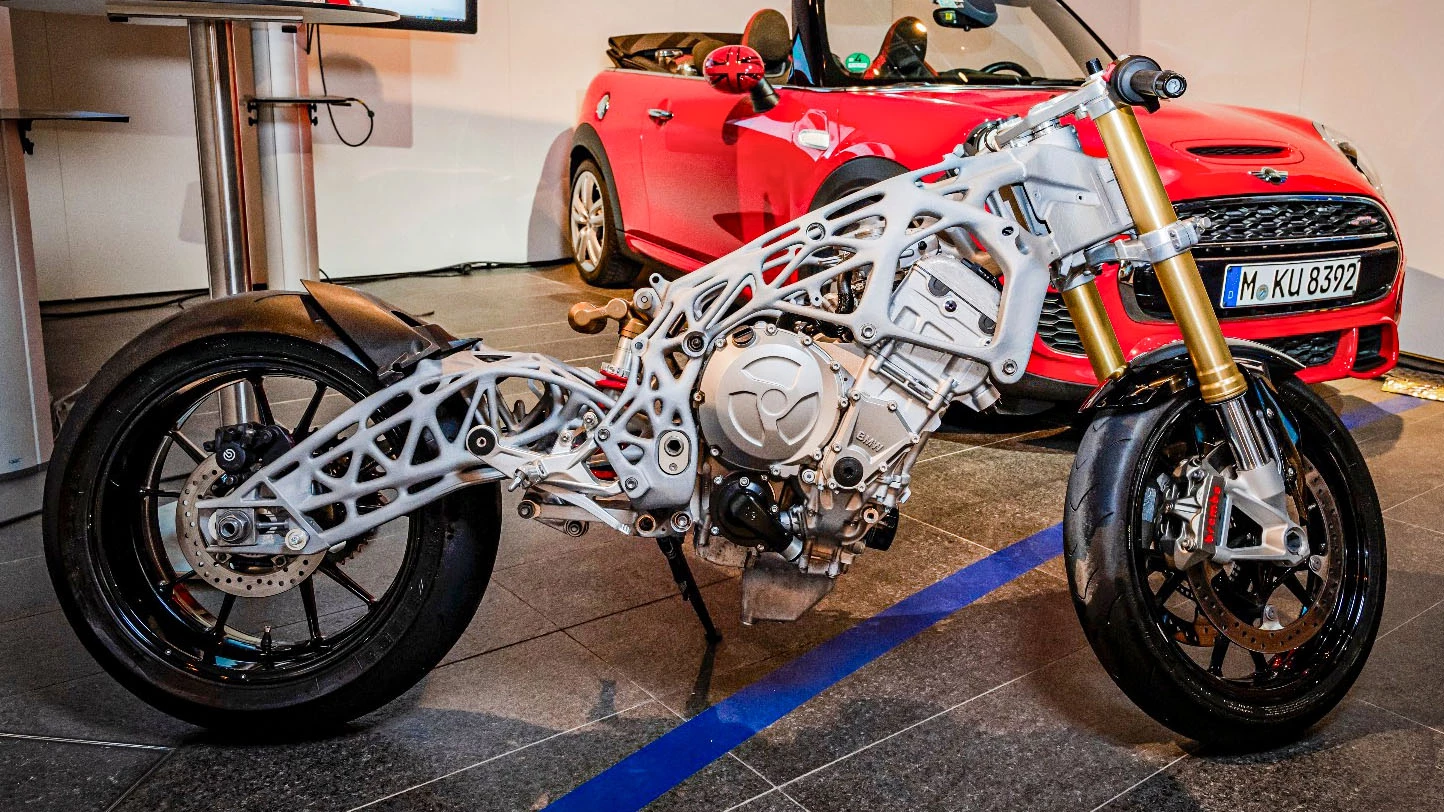

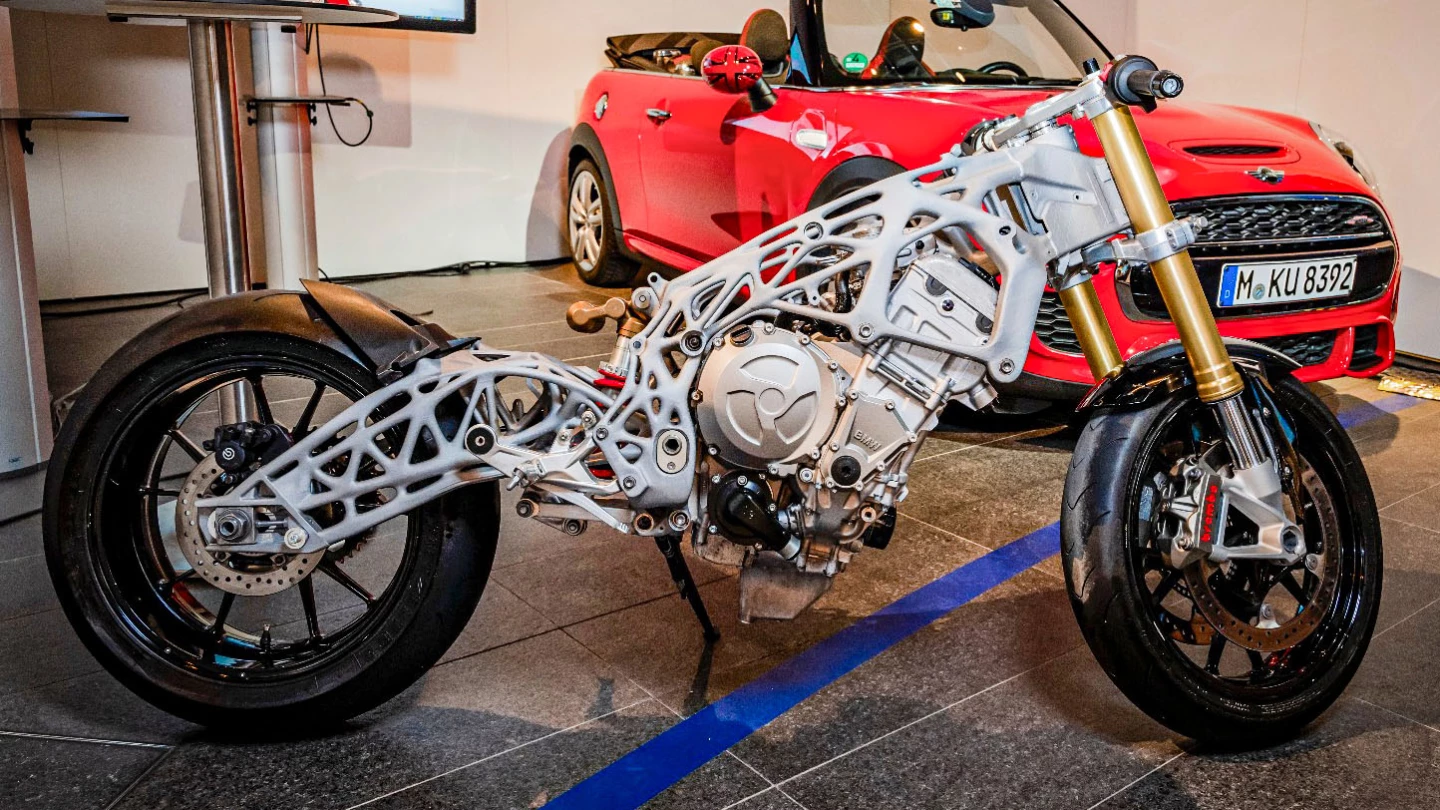

But to get some sense of what's possible, take a look at what BMW was able to achieve using generative design and 3D printing to create this wild S1000R superbike chassis prototype back in 2018:

We can't wait to see what Stark will build with this crazy technology – but we're certain it'll be nothing short of revolutionary.

Source: Farsoon Technologies via MCNews.com.au