What has opposable thumbs and is the most dexterous tool on the planet? The human hand, obviously. Well … not anymore. At least according to engineers at École Polytechnique Fédérale de Lausanne’s (EPFL) school of engineering, who have developed a robotic hand capable of outperforming human dexterity in controlled manipulation tasks.

For centuries, researchers have regarded the human hand as the benchmark for dexterity. As a result, robotic hands were typically designed to replicate the structure and functionality of human hands. However, this also meant replicating their limitations. While human-inspired robotic hands, from grippers to bionics, are capable of pinching, grasping, and lifting just fine, their functionality has always been limited by what we think is possible.

Think about it. What would we be able to do with more than one thumb? What if our fingers could bend outward and not just inward towards our palms? Can one hand perform more than one task at a time, say picking up a pen while grasping a bottle?

“We can easily see the limitations of the human hand when attempting to reach objects underneath furniture or behind shelves, or performing simultaneous tasks like holding a bottle while picking up a chip can,” says Aude Billard, head of the Learning Algorithms and Systems Laboratory (LASA) in EPFL’s School of Engineering.

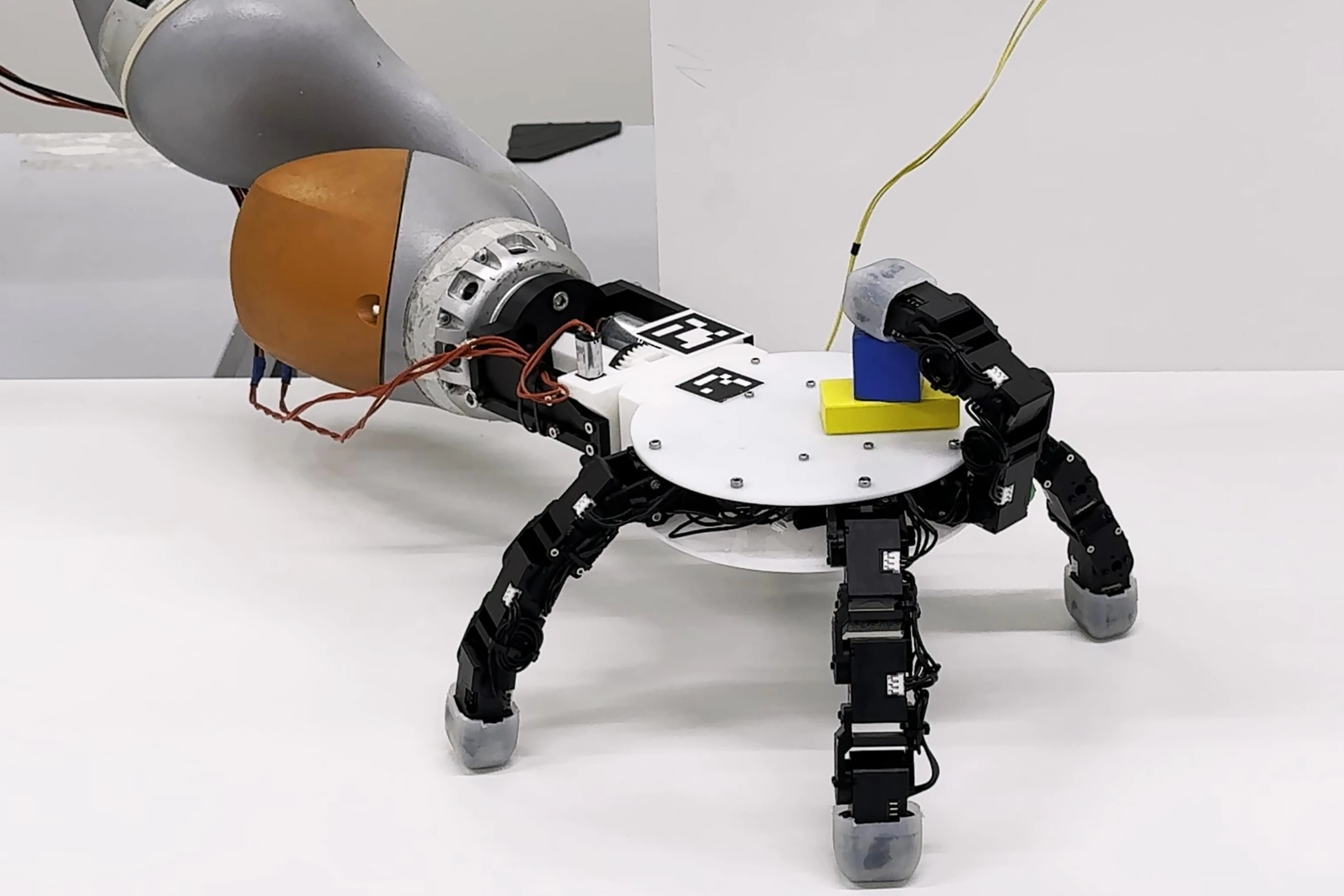

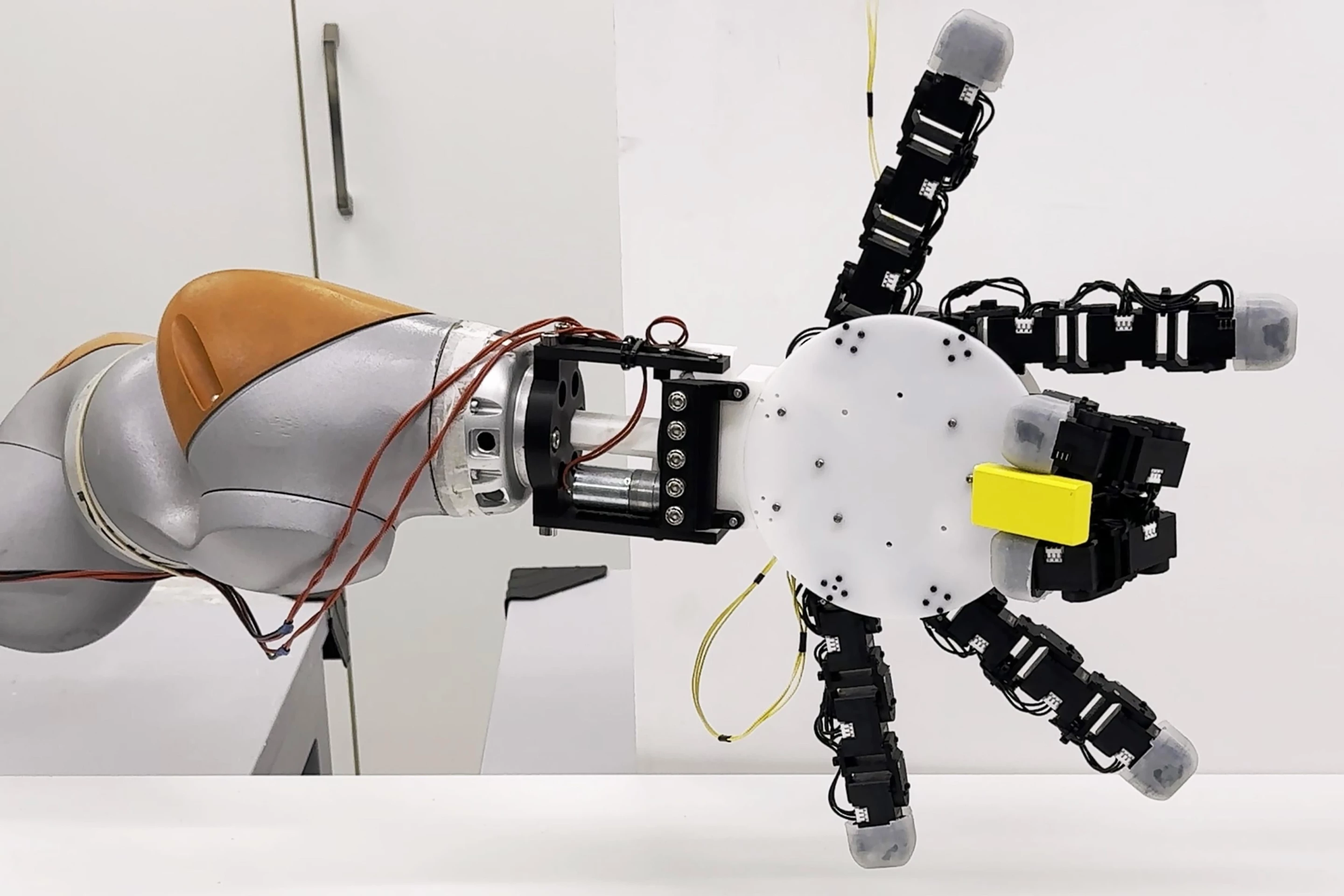

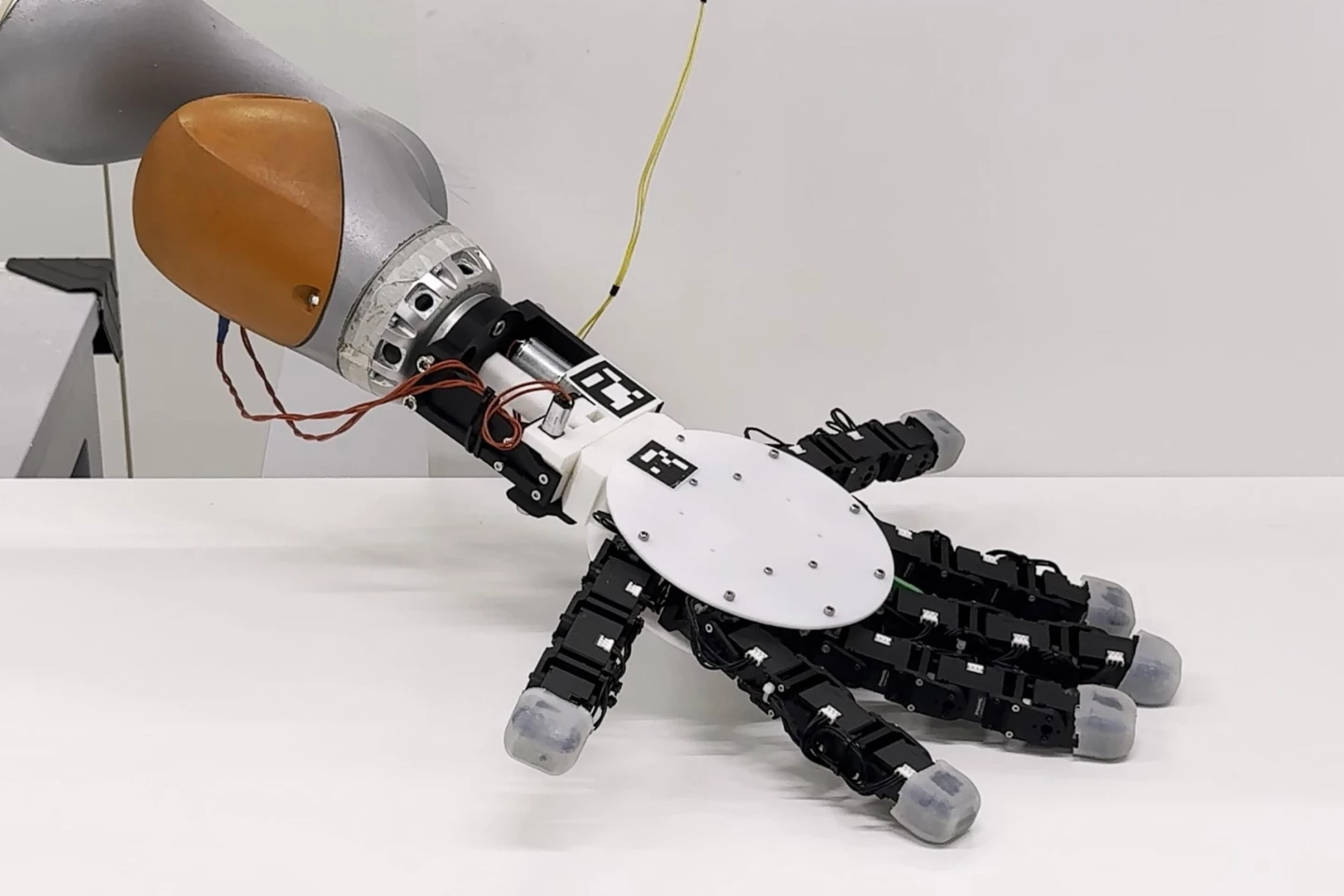

To answer these questions and build beyond human limitations, the team at EPFL designed and produced a highly dexterous, modular robotic hand. This device, which features up to six identical silicon-tipped fingers, is capable of performing 33 different types of human grasping motions. Departing from traditional human asymmetric design, the hand features symmetrical architecture that allows any combination of fingers to form a thumb-like pinch.

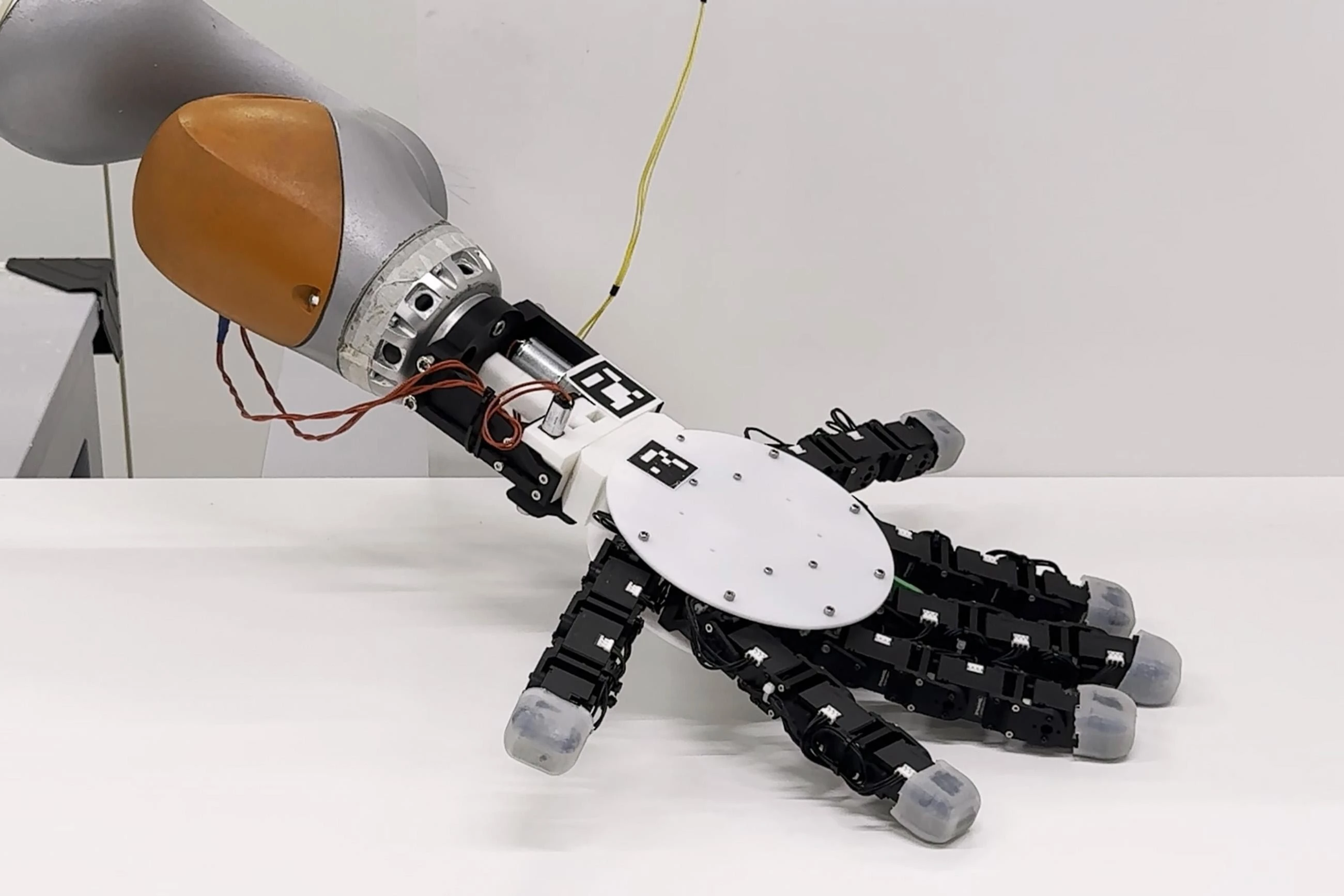

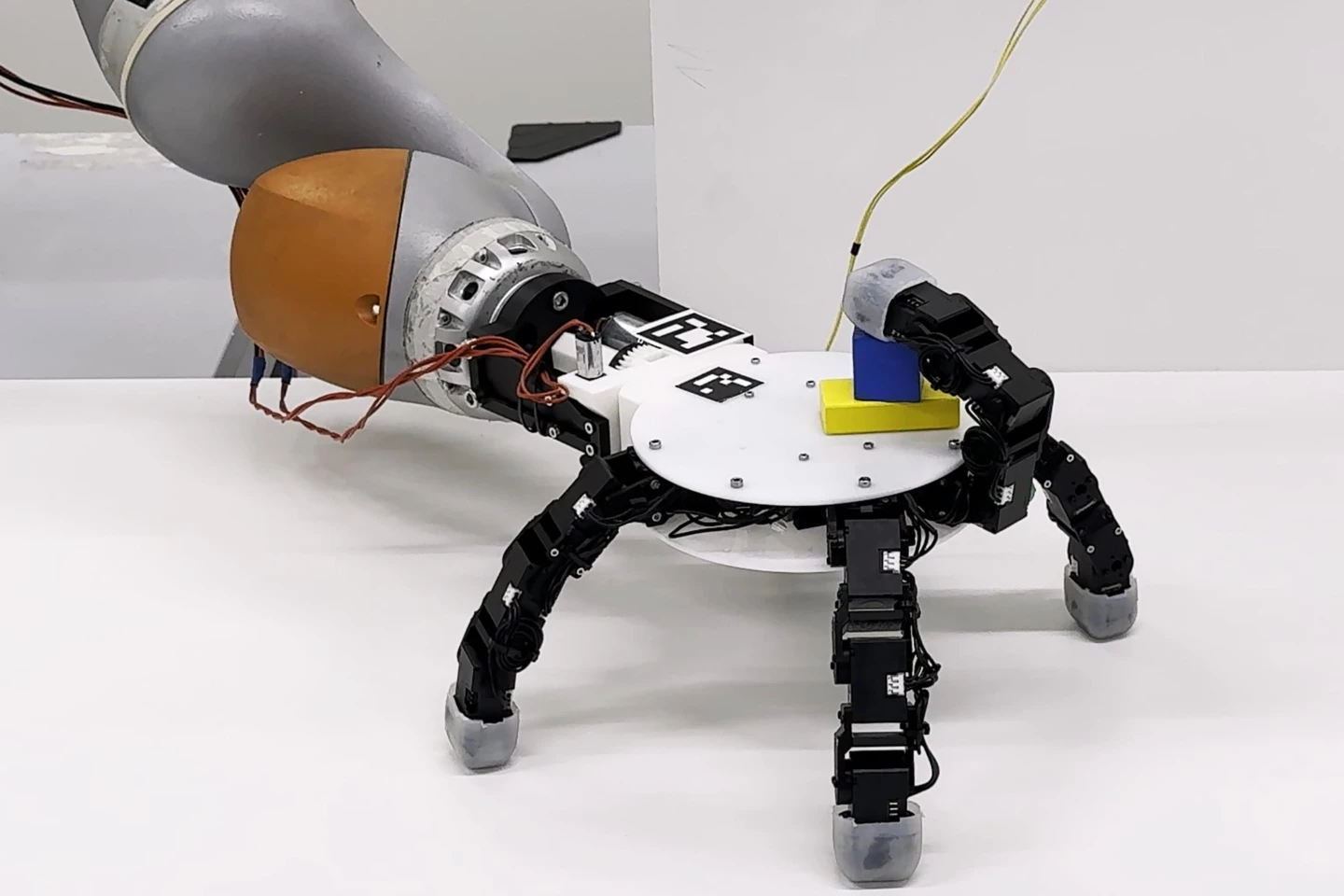

What’s more, the two outermost fingers can reposition to form opposable thumbs at either end of the hand. That’s two opposable thumbs per robotic hand. Take that, human hands! Further symmetrical design eliminates the limitations of a defined “palm” and “back” of the hand. The fingers can simply bend backward, reversing the position of the “palm.”

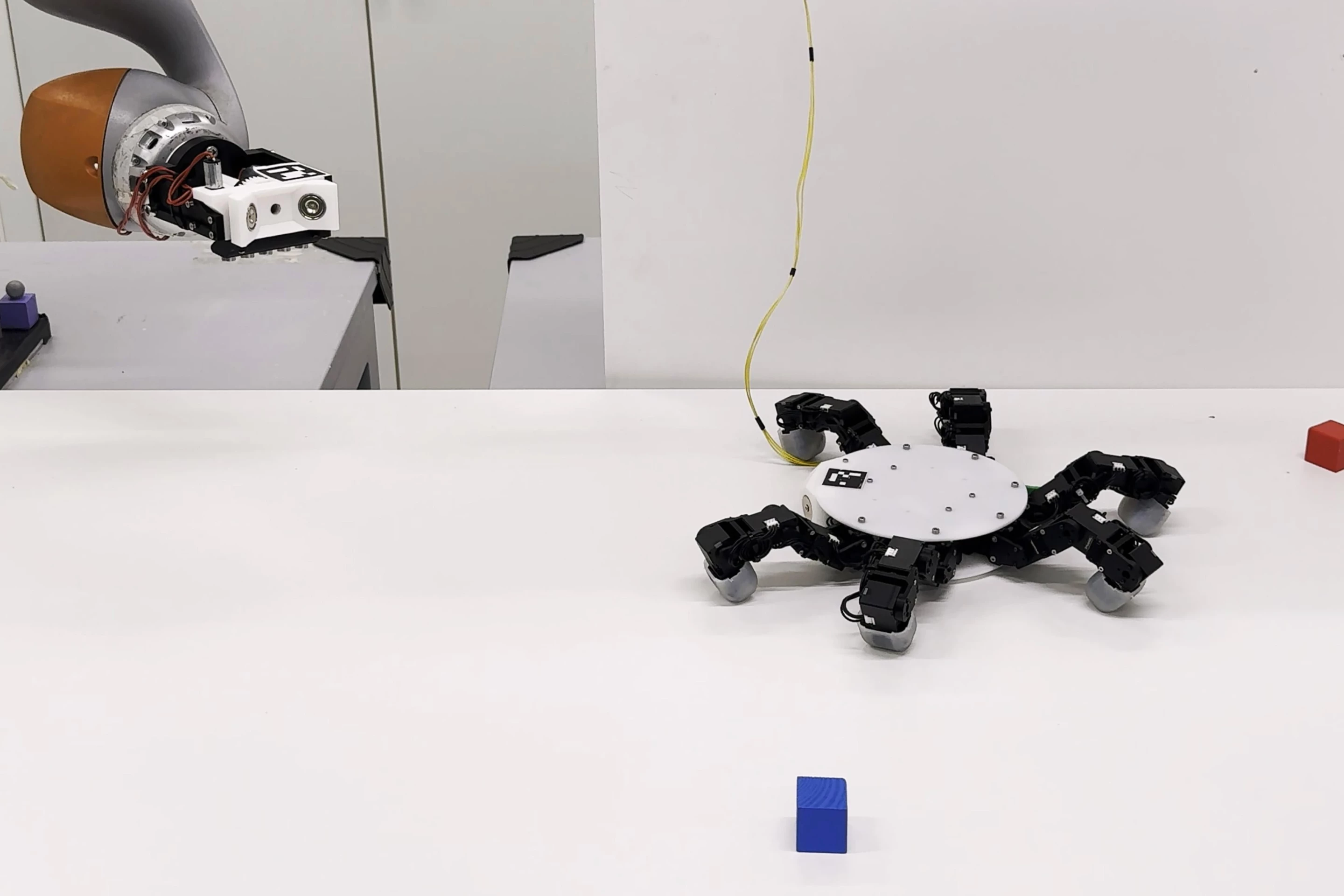

Have you ever had to utilize a tool or reposition your body to interact with an object that was out of reach? This scenario does not pose a challenge for the robotic hand, as it can detach from the robot arm. Each one of the fingers is capable of operating autonomously, allowing the hand to crawl beyond the arm’s reach.

“Our device reliably and seamlessly performs ‘loco manipulation’ – stationary manipulation combined with autonomous mobility – which we believe has great potential for industrial, service, and exploratory robotics,” Billard explains.

For fans of the fictional Addams family, this capability makes the device eerily reminiscent of the character, “Thing,” except with far more dexterity. In reality, the researchers cite nature as the primary inspiration for the hand’s design.

“Many organisms have evolved versatile limbs that seamlessly switch between different functionalities like grasping and locomotion. For example, the octopus uses its flexible arms both to crawl across the seafloor and open shells, while in the insect world, the praying mantis use specialized limbs for locomotion and prey capture,” Billard says

The combination of autonomous mobility and the various dexterity features of the robotic hand provides capabilities far beyond human hands and existing devices. Its symmetrical design and ability to independently control each identical finger mean the hand can crawl, secure objects on its “back,” and manipulate tools all at once.

The team of researchers believe that their design has far-reaching applications, particularly in settings that demand high dexterity, adaptability, compactness, and autonomous control. For example, while medical robotic arms already demonstrate impressive precision, the team’s hand could provide an exponentially beneficial layer of functionality. The ability to retrieve, hold, and operate multiple tools simultaneously would undoubtedly increase the speed and accuracy of surgical procedures.

The same advantages extend to military and defense contexts, such as bomb disposal or the retrieval of objects from confined or hazardous spaces. Industrial assembly is another natural fit, where delicate, multi-step manipulation is often required. In fact, any task or industry that relies on fine dexterity, from sewing to coffee making, could benefit from such a system.

“The symmetrical, reversible functionality is particularly valuable in scenarios where users could benefit from capabilities beyond normal human function,” Billard says

You may be wondering whether this robotic hand could replace a real human hand. While the hand is not currently designed as a prosthetic, the researchers believe that it can be adapted for this purpose.

A paper detailing this research was recently published in the journal Nature Communications.

Source: EPFL