The Harmonic Drive is a key part of countless robotic applications. Incredibly simple yet quite odd to watch, this gear system is extremely precise with an impressive torque-to-weight ratio, even if it does wobble. So how does it work?

The seemingly bizarre Harmonic Drive gear is actually rather genius in how it functions – its flexible-ellipse-within-a-circle setup creates a wobbling motion as it turns, and places only about a third of its two main gears' teeth in contact with each other at any given point – but the result is a remarkably compact and lightwight little drive gear capable of delivering excellent torque with absolute precision, and zero drive lash or free play.

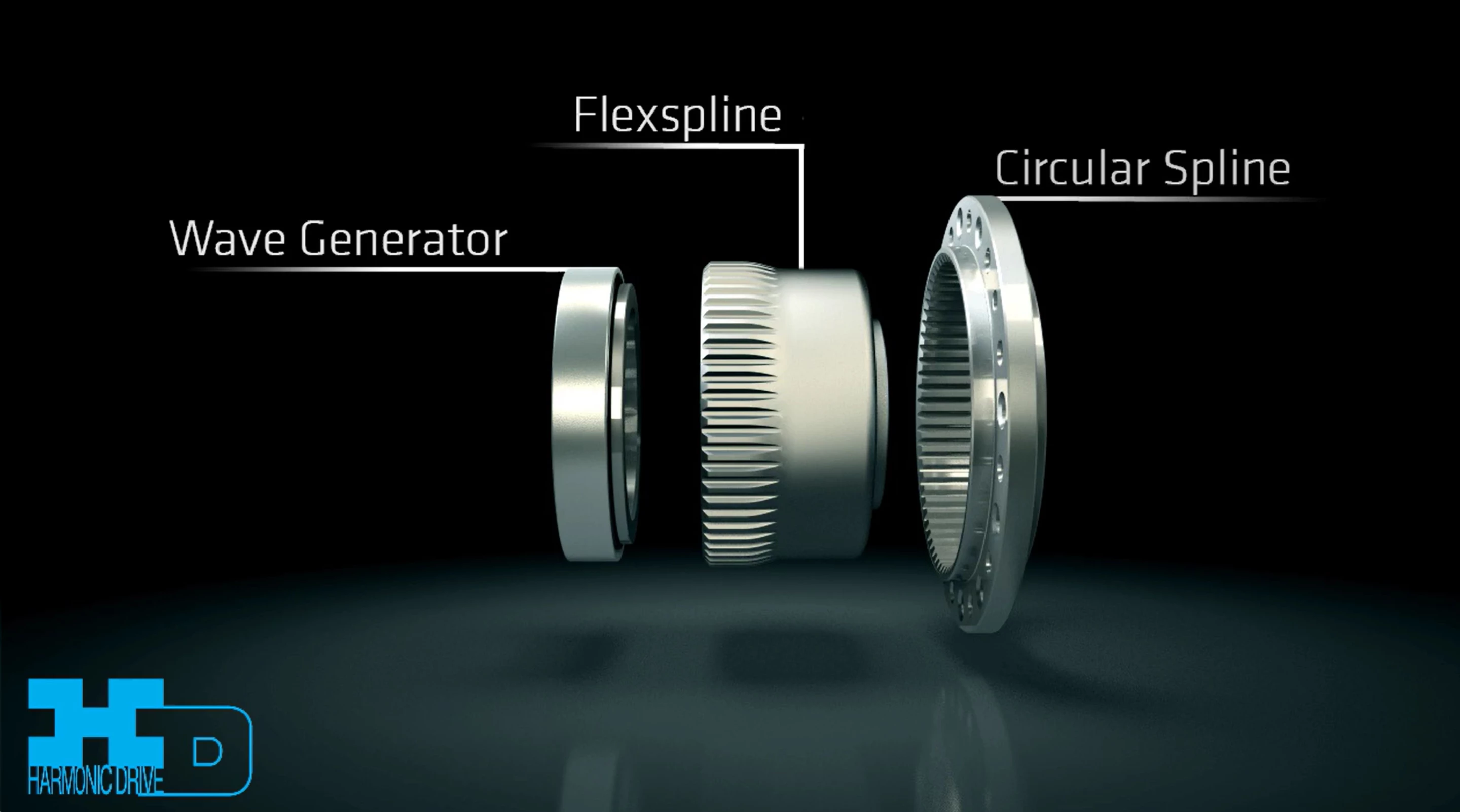

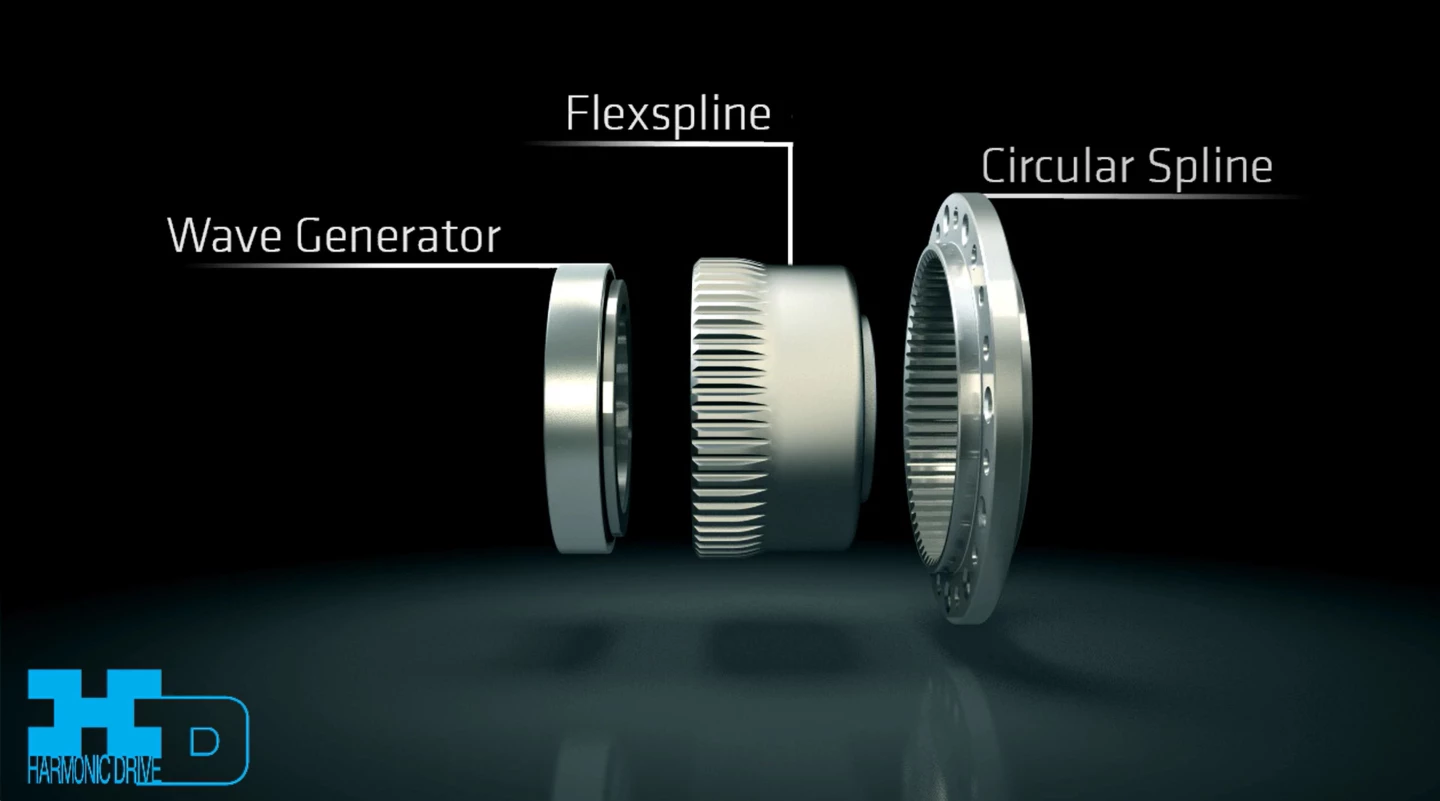

It was first conceived in 1957 by Pennsylvania's C. Walton Musser, a wonderfully creative inventor with patents on everything from power steering systems, recoilless rifles and pneumatic life jacket inflators, through to many key ideas underpinning jet aircraft ejection seats. The Harmonic Drive was first commercialized by the early 1960s. It's made of three key components:

- The wave generator: A slightly elliptical input hub with a ball bearing race around its outer edge.

- The flexspline: A flexible, cup-shaped component with teeth on its outer perimeter. It deforms radially but retains torsional rigidity when the oblong wave generator is inserted.

- The circular spline: A completely rigid ring with internal teeth, similar to a planetary ring gear, and with two more teeth than the flexspline.

When the wave generator spins, about 30% of the flexspline's teeth on either end make contact with the circular spline's teeth at any given time, forming an advancing wave pattern. This causes the flexspline to rotate within the circular spline, but in the opposite direction of the input. Check it out:

Part of this system's genius is its zero backlash – there's no play between the gears, making it ideal for precise, fine motor control. Its compact, lightweight design is also perfect for applications with limited space. And with few moving parts, the Harmonic Drive is highly reliable and durable.

Today, Harmonic Drives are everywhere on and off planet. Industrial robots like those from Fanuc and Universal Robots use them for tasks such as welding and assembly, where repeatable, precise motion is critical.

The da Vinci surgical robot, designed for minimally invasive procedures, relies on Harmonic Drives in its arms, giving it delicate micro-movements with zero backlash for the utmost precision while performing minimally invasive operations on people.

Boston Dynamics' Atlas humanoid and Spot Quadruped robots use them in their arms and legs, among other places, to achieve smooth, controlled motion while still being strong.

Even NASA's Mars rovers, Curiosity and Perseverance, feature Harmonic Drives in their robotic arms and wheels. Sending rovers to another planet with no hope of maintenance or repair stops is a testament to the reliability and durability of this design.

While Musser never lived to see his invention reach Mars, he did at least witness it go to space. The Harmonic Drive was common component in the Space Shuttle's standard-issue Remote Manipulator System – aka "Canadarm" – used on shuttles like Columbia and Challenger to handle payloads and deploy cargo.

Nearly 70 years after its creation, this remarkable invention, with its distinctive yet purposeful "wobble," continues to be found across diverse fields. From precise surgical movements to the exploration of distant planets, the Harmonic Drive's genius lies in its simplicity, reliability, and precision.

Source: Harmonic Drive