Over the past few years, chocolate fans may have noticed a concerning change in the taste and texture of their favorite brands, due to confectioners adjusting their recipes in response to global cocoa shortages and sky-high prices.

According to the International Cocoa Organization (ICCO), cocoa production dropped in 2023/2024 specifically from Africa, which exports the majority of the world’s supply. This was caused mainly by factors such as drought, climate issues and crop diseases.

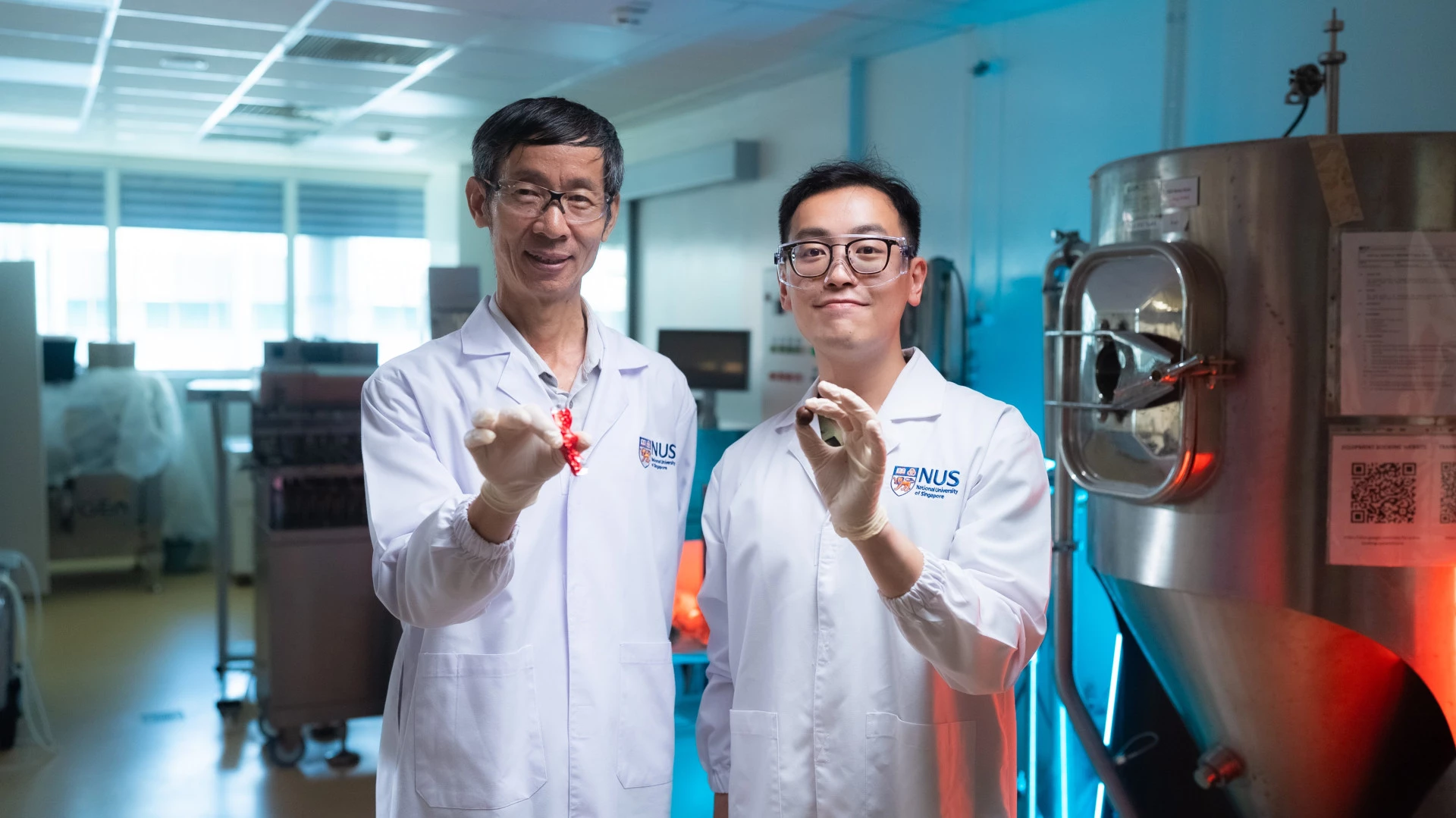

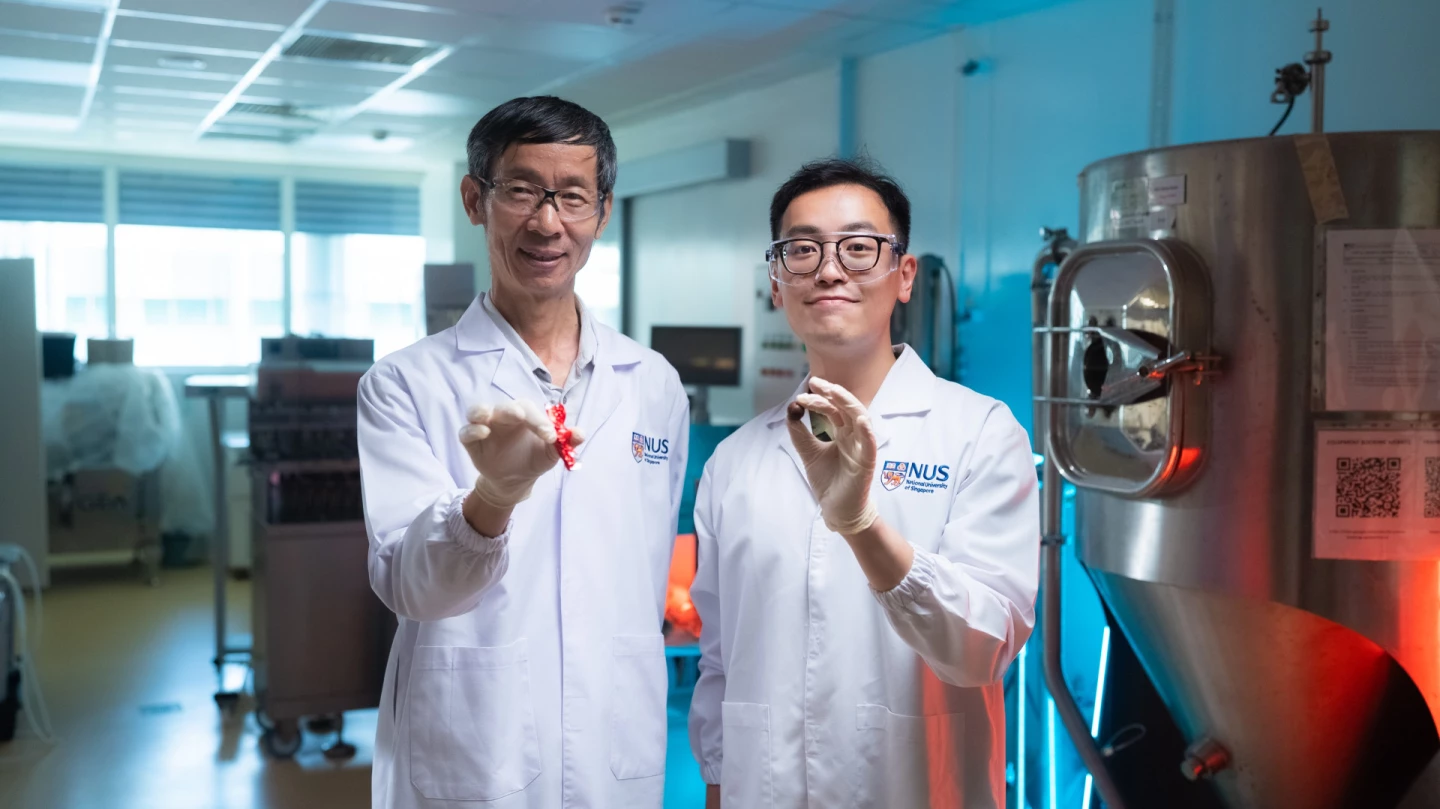

In response to this concern, a research team from the National University of Singapore (NUS) led by Assoc. Prof. Liu Shao Quan has developed two innovative processes to improve the taste of carob pulp to produce a sustainable cocoa alternative.

Carob pulp is a by-product derived from locust bean gum, a thickening agent used in the food industry that produces an aroma similar to that of cocoa when roasted. However, it lacks the rich roasted flavors found in cocoa. Carob on its own has a natural sugar content, is less bitter than chocolate, caffeine-free and rich in d-pinitol, a compound that has been shown to have anti-diabetic effects.

The carob tree (Ceratonia siliqua) is a robust drought-tolerant tree native to the Mediterranean region, where it thrives in the arid climate. On the other hand, the Theobroma cacao tree – the source of cocoa – requires rainy humid regions with stable temperatures, where it's sheltered from the wind.

In the first of the NUS processes, an enzyme-treated soy protein is applied to the carob pulp. Doing so increases the carob's bitterness (making it taste more like chocolate), produces the flavor compounds 2-methylbutanal and 3-methylbutanal (making it smell more like chocolate), reduces its less desirable carob-like odors, and generally balances its overall taste to match that of dark chocolate.

In the second process, a food-friendly enzyme is utilized to promote the creation of naturally occurring sugars in the carob during roasting by inducing a caramelizing reaction. This generates sweet caramel-like aroma compounds (oxygenated-heterocycles) that result in a more rounded, smoother flavor balance.

Currently, carob is most often found in health-conscious cafes and restaurants due to its reputation as a naturally sweet chocolate substitute, and mainly ignored by major chocolate manufacturers due to its muted taste. The NUS researchers hope their flavor enhancements will inspire major confectioners to adopt carob usage to a wider degree, which could reduce the industry’s reliance on cocoa.

“Our research is not just about replicating the flavor of cocoa – it’s about diversifying the ingredients we use to make chocolate alternatives,” explained PhD student Manfred Ku, first author of the study. “By turning to hardy, climate-resilient crops like carob, we can help the industry adapt to environmental challenges while giving consumers a product they will enjoy.”

The researchers also predict the lower production costs will be an enticement for chocolate makers to create carob-based treats, since the carob pulp is a by-product from locust bean gum refinement.

“Our carob-based innovation meets the relatively untapped and nascent market of alternative chocolate sources," said Assoc. Prof. Liu. "Additionally, our new techniques improve the taste of carob itself, without the use of additives such as flavorings. So, consumers can have the best of both worlds – better flavor and a simple ingredients list. With these innovations, we aim to make a meaningful contribution towards addressing the current challenges and needs of the chocolate industry."

A paper on the research was recently published in the Journal of Food Science.

Source: National University of Singapore