Engineers at the University of Minnesota have developed a new system that can move objects without making physical contact. The technique involves ultrasound waves acting on specialized surfaces to push or even pull objects in different directions, which could help in manufacturing and robotics.

If you want to move something, you usually have to touch it, but in some cases where items are fragile or sensitive that’s not ideal. Contactless manipulation is a growing area of research into technologies that could impart a force onto objects to move them without any physical contact necessary.

This often involves using ultrasound waves or light beams, which can exert enough pressure to levitate or move certain objects. But unsurprisingly, these objects usually need to be extremely tiny and/or light, which limits the usefulness of the technique.

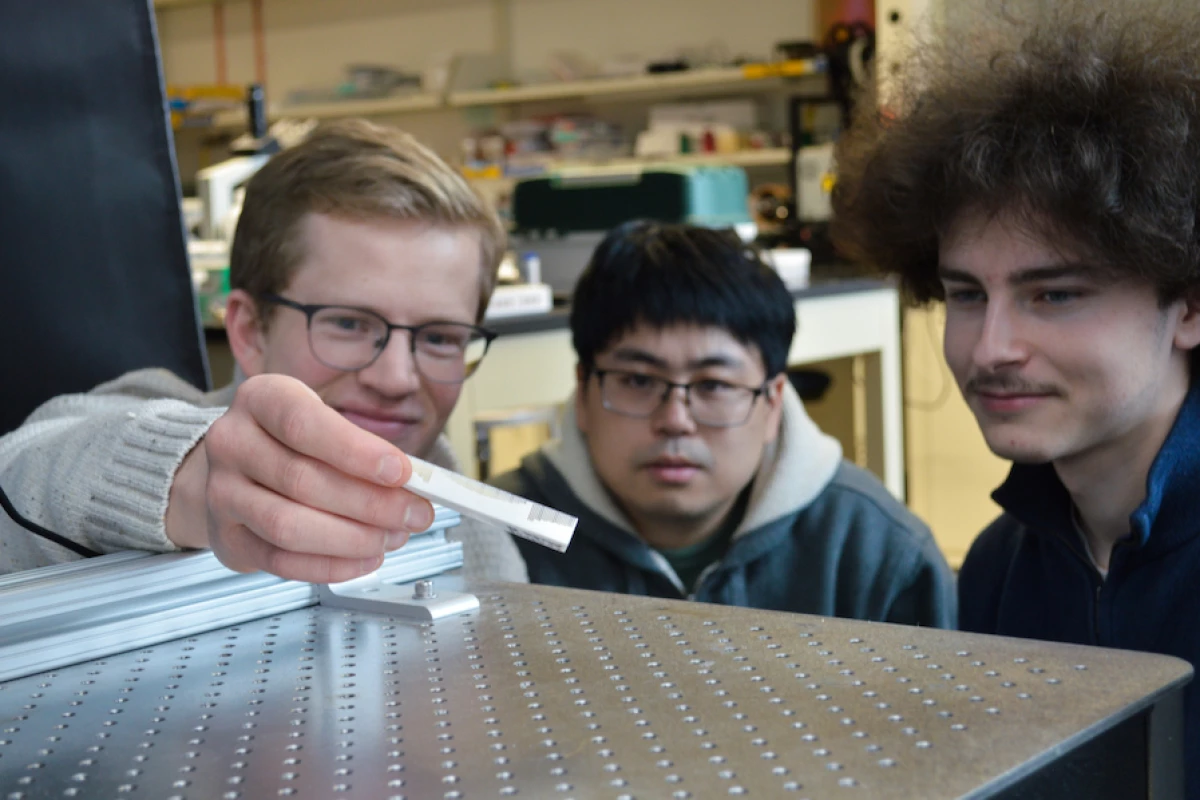

For the new study, the researchers experimented with a new way to move larger objects without touching them. The target object is fitted with a metamaterial surface that’s been specially designed to reflect the sound waves in ways that can move an object backwards, to the side, or even forwards like a tractor beam.

“What sets our research apart is that we can manipulate and trap much bigger objects if we make their surface a metamaterial surface, or a ‘metasurface,'” said Ognjen Ilic, senior author of the study. “When we place these tiny patterns on the surface of the objects, we can basically reflect the sound in any direction we want. And in doing that, we can control the acoustic force that is exerted on an object.”

This technique does introduce its own limitations though. It can’t be used to move just any old thing, since the target needs to have a specific metasurface designed, etched and attached before it’ll work. And after all that, you’d need to swap the metasurface if you wanted the object to move in a different fashion. That said, it could come in handy for specific repeated movements in situations like production lines.

The research was published in the journal Nature Communications. The acoustic metasurface can be seen in action in the video below.

Source: University of Minnesota