3D printing promises that one day we may be able to print out goods in our own homes rather than popping down to the shops or ordering widgets online. But what happens when the printers are able to print themselves? Boots Industries’ BI V2.0 takes a step down that road with a design aimed at self-replication. Currently the subject of a Kickstarter campaign, the open-source printer is capable of printing its own core components.

Founded in 2012 by Jean Le Bouthillier and François Crête, Boots Industries already has several other printers on the market, but the BI V2.0 is something of a departure for the company. It’s an open, large build-volume printer with clearances designed to allow for maximum use of the space inside the frame for high-precision printing.

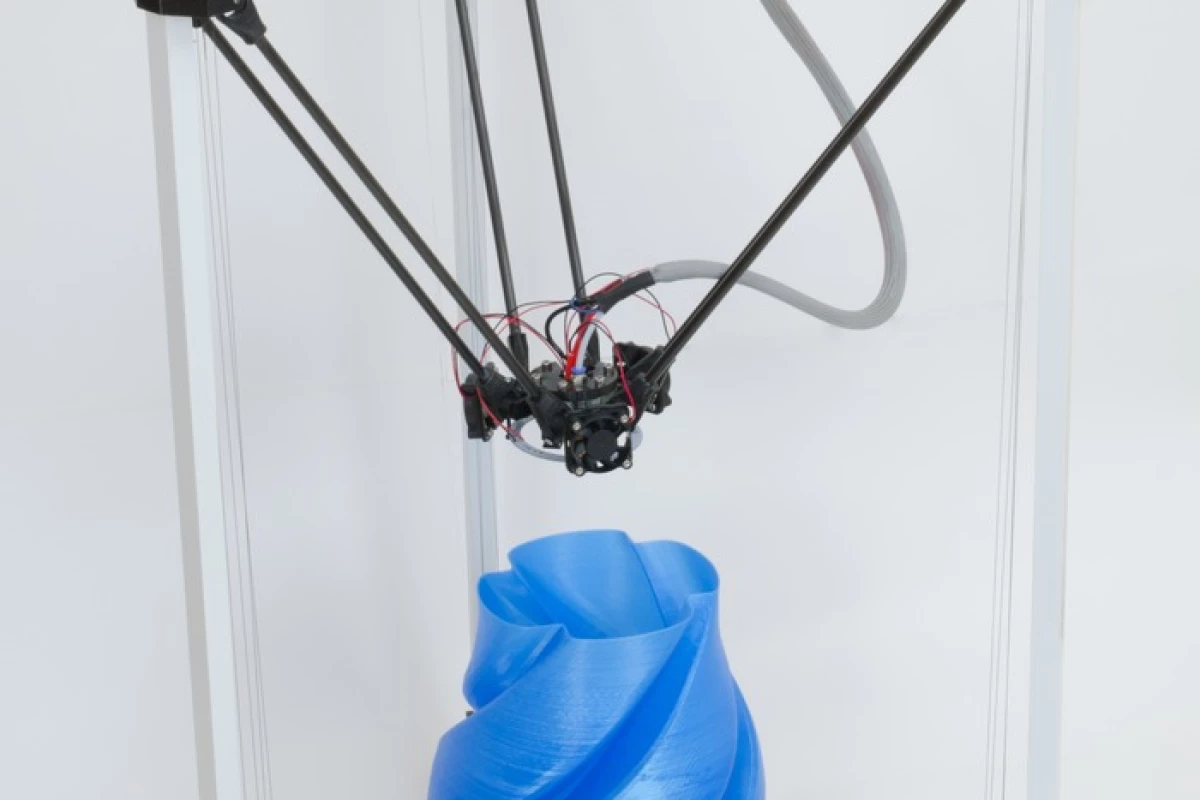

The key to the BI V2.0 is that it’s a delta-style 3D printer, based on the delta robots developed in the 1980s for picking up small objects rapidly and precisely. From each edge of the triangular frame sprout arms that meet at in effector head in the middle. These arms form parallelograms, which keep the effector level as the arms change position.

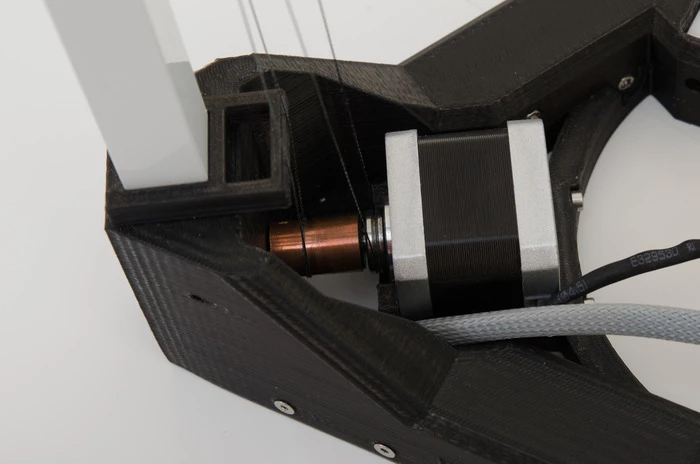

The arms are powered by NEMA 17 motors with 32x microstepping, and are raised and lowered using pulleys strung with 50-lb (22.6-kg) test spectra line to eliminate stretching These are set in vertical aluminum extrusions, which are held together with steel-reinforced 3D-printed corners and 0.75-in (19-mm) anodized aluminum extrusions to form a 300-mm (11.8-in) wide, 300-mm high printing area. The arms run on 3D- printed linear bearings, which are as precise as ball bearings, but quieter.

The design incorporates sleeved wiring with quick disconnects for easy maintenance, and the company says that the whole printer takes only 30 minutes to an hour to put together.

The working end of the printer is a redesigned 0.4-mm JHead for the extruder that can use a wide variety of 1.7-mm plastic filaments at temperatures up to 250º C (482º F). Boots says that the modifications allow faster printing speeds and, by eliminating backflow, clogging is "virtually non-existent." There’s also an auto-level probe that measures the height of the extruder over the test bed and adjusts accordingly, so layering is consistent.

The printer is operated using its onboard LCD controller, which allows the user to move the printer, set speeds and temperatures, and start printing from patterns on the 4 GB SD card that comes as standard. Also standard is the heat bed that forms the base of the printer, which allows proper adhesion, and prevents warping. Meanwhile a triple fan assembly controls temperature in the workspace and an LED ring provides illumination.

But the singular feature of the BI V2.0 is Boots’ ambition to make it self-replicating. Of course, since the printer can only handle plastic, it can’t make a complete replica of itself, but Boots says that it can make copies of its own core components and that the other parts of the machine are designed to be readily obtainable. The company also intends to make all of its 3D models open source in the Sketchup format.

Though Boots claims to already have the BI V2.0 fully developed, it's running a Kickstarter campaign until January 22 to raise funds for fine-tuning the printer kits for packaging, as well as working with local providers to improve packaging and shipping. If the campaign is successful, the BI V2.0 will be available to those who pledge US$685 as a premium and the Kickstarter printers will ship before the online store opens, where the BI V2.0 will sell for $799.

The video below introduces the Boots Industries BI V2.0 3D printer.

Sources: Boots Industries, Kickstarter